Device for measuring shearing force of metal part

A measuring device and shearing force technology, applied in the direction of measuring device, using stable shearing force to test material strength, using force balance force measurement, etc., can solve the problem of not fully reflecting the real situation and strength, calibration and solution Problems such as complicated process and complicated testing and testing equipment can achieve the effect of high testing efficiency, high measurement response speed and precision, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

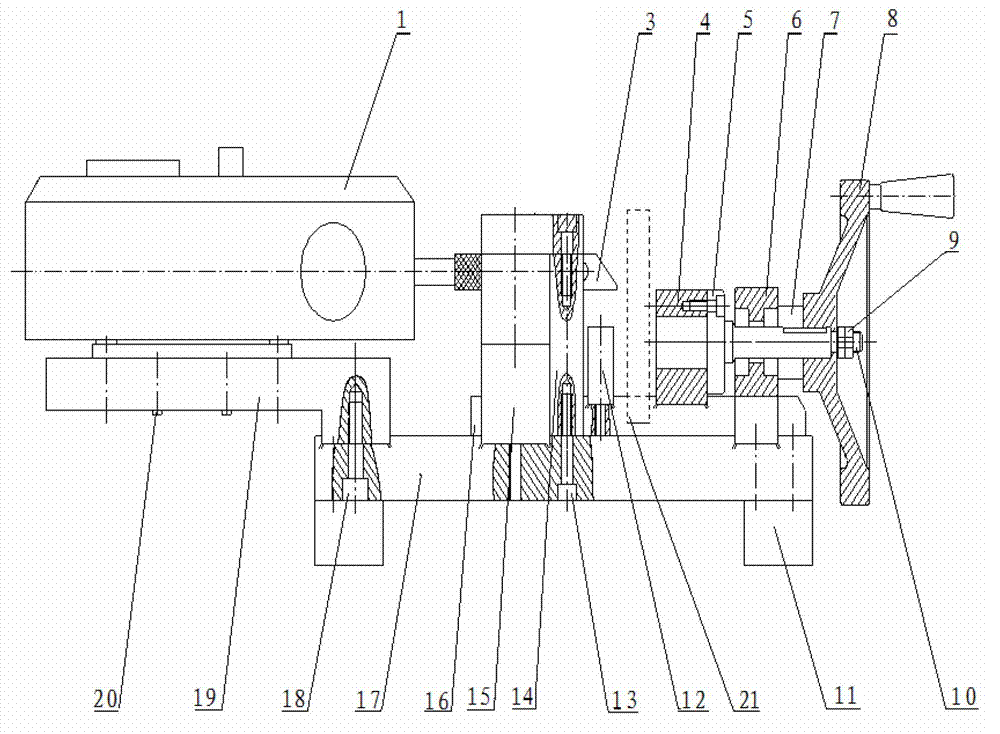

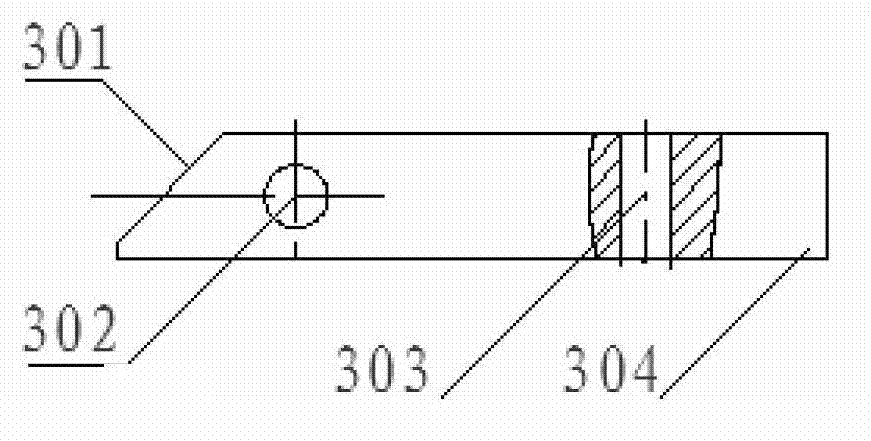

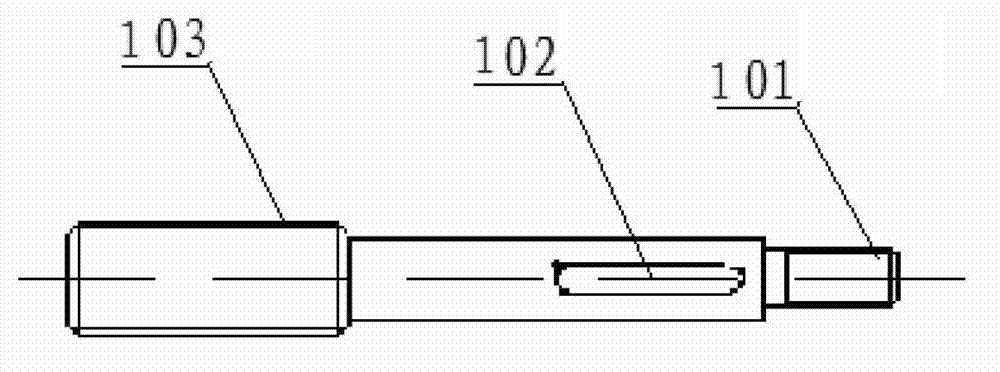

[0013] Such as figure 1 As shown, a metal piece shear force measurement device includes a large base plate 17, the top of the large base plate 17 is connected to the side support plate 19 through the first hexagonal socket screw 18, and the dynamometer 1 is fixed on the side support plate 19 through the small screw 20. , the shaft end of the dynamometer 1 is connected to one end of the working block 3 . The structure of work block 3 is as follows figure 2 As shown, one end is directly connected to the shaft end of the dynamometer 1 at a straight angle, and the other end has an oblique shear surface 301 and faces one end of the module 21 to be tested. There are horizontal holes 302 and vertical holes 303 on the working block 3, The horizontal hole 302 is connected to the clamping block 14, and the clamping block 14 is fixed to the slide plate 16 by the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com