Process and device for preparing alkali by full-brine mechanical steam recompression method

A mechanical steam and recompression technology, which is applied in the field of industrial soda production, can solve the problems of electrolytic cell current efficiency drop, heat energy loss, and large footprint, so as to reduce the dependence on boiler equipment, reduce the dependence on boiler equipment, and occupy an area of equipment The effect of less area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

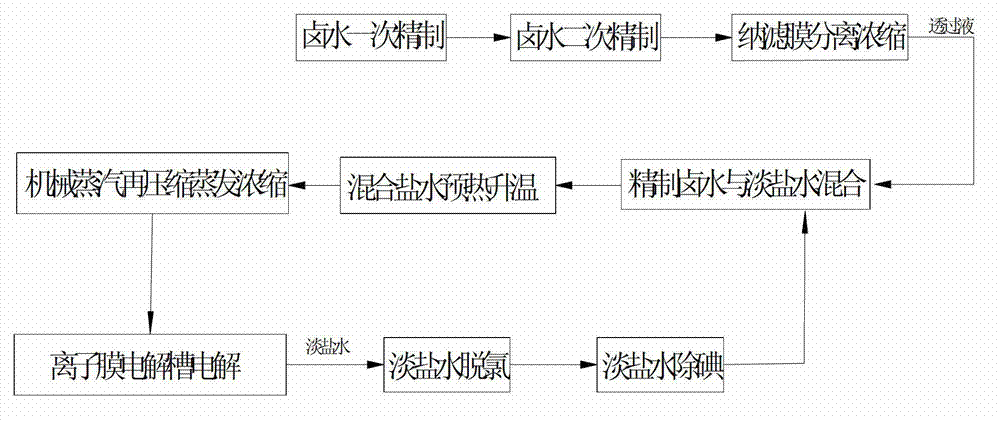

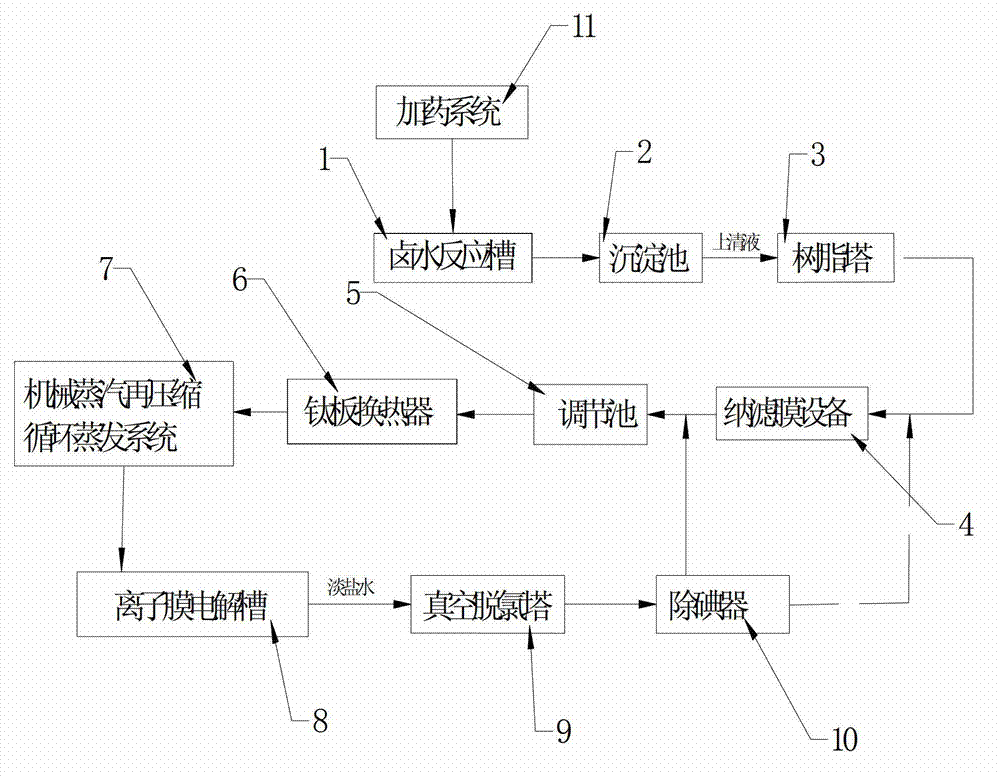

[0039] Please refer to figure 1 , the whole brine mechanical steam recompression method alkali making process of the present invention comprises the following steps:

[0040] 1) One-time refining of brine: put caustic soda-soda ash into raw brine to make Ca 2+ , Mg 2+ 、Ba 2+ 、Al 3+ 、Sr 2+ Metal ions react chemically to form precipitates, thereby removing Ca 2+ , Mg 2+ 、Ba 2+ 、Al 3+ 、Sr 2+ and other metal ions;

[0041]2) Secondary refining of brine: the brine after primary refining is sent to the chelating resin tower for ion exchange to further remove Ca 2+ , Mg 2+ 、Ba 2+ 、Al 3+ 、Sr 2+ Wait for metal ions, reduce the concentration of metal ions in brine, and meet the requirements of entering the ion-exchange membrane electrolyzer;

[0042] 3) Nanofiltration membrane separation and concentration: After step 2), the brine treated in step 2) is first adjusted to a pH between 5-8 and a temperature between 20-38°C, and then separated and concentrated through a nanof...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 is that after the brine is firstly refined, the precipitated salts and impurities are firstly filtered and purified through a tubular membrane filter, and then the brine is secondarily refined.

Embodiment 3

[0052] The difference between this example and Example 1 is that in order to protect the ion-exchange membrane electrolyzer and prolong its service life, the brine evaporated and concentrated in step 7) was first adjusted to a pH of 11 and a temperature of 65°C before electrolysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com