Online cooling water temperature difference measuring system for wireless blast furnace

A measurement system and cooling water technology, applied in cooling devices, inspection devices, etc., can solve the problems that lines are susceptible to high temperature, water vapor erosion, affecting temperature measurement, wiring difficulties, etc., to achieve easy sealing, simple transmission, and good interchangeability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

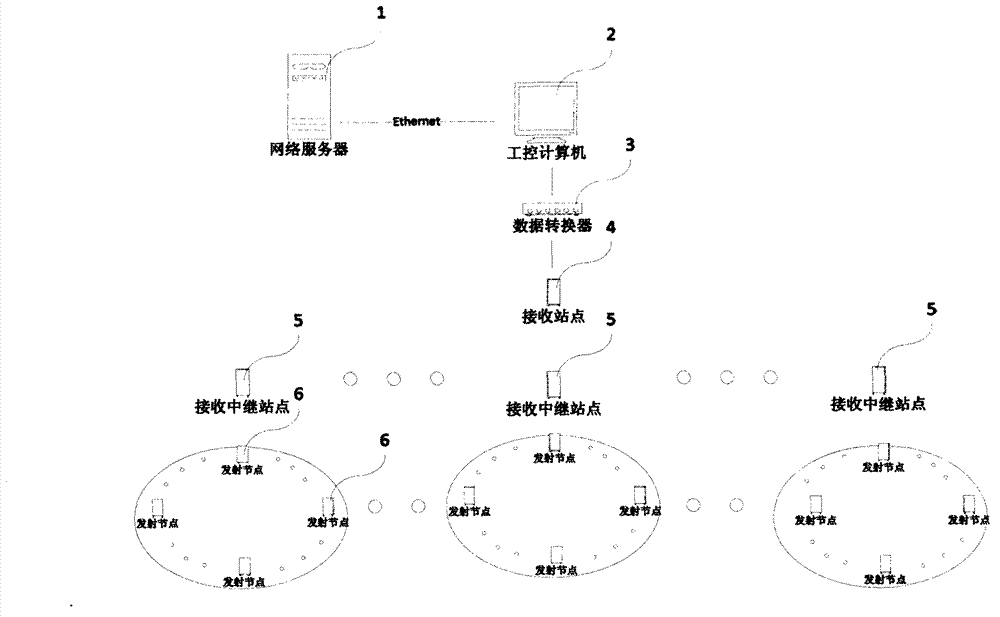

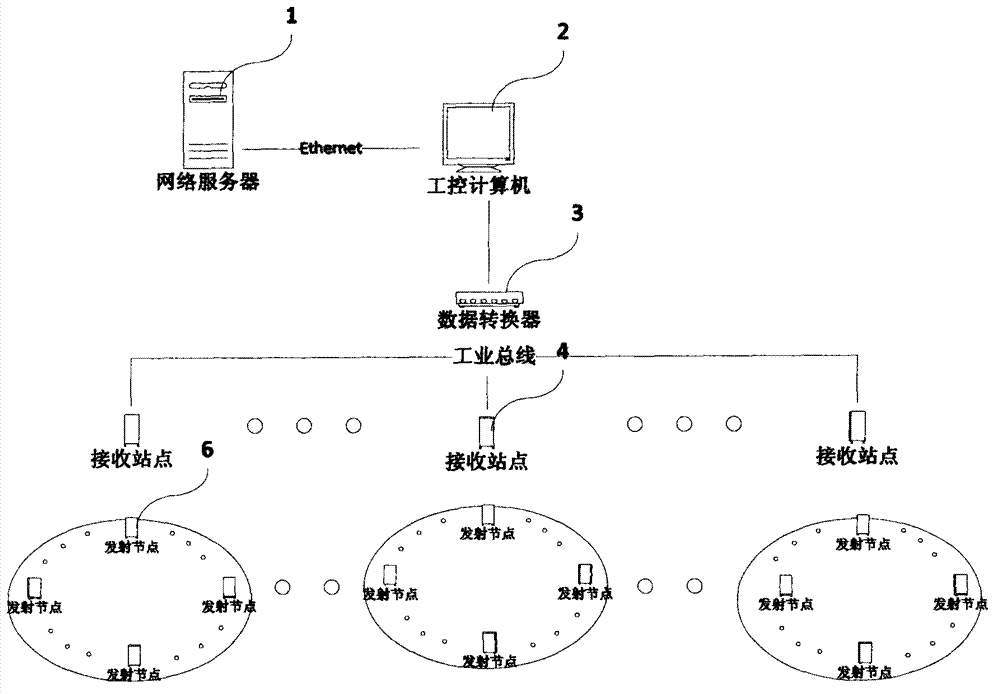

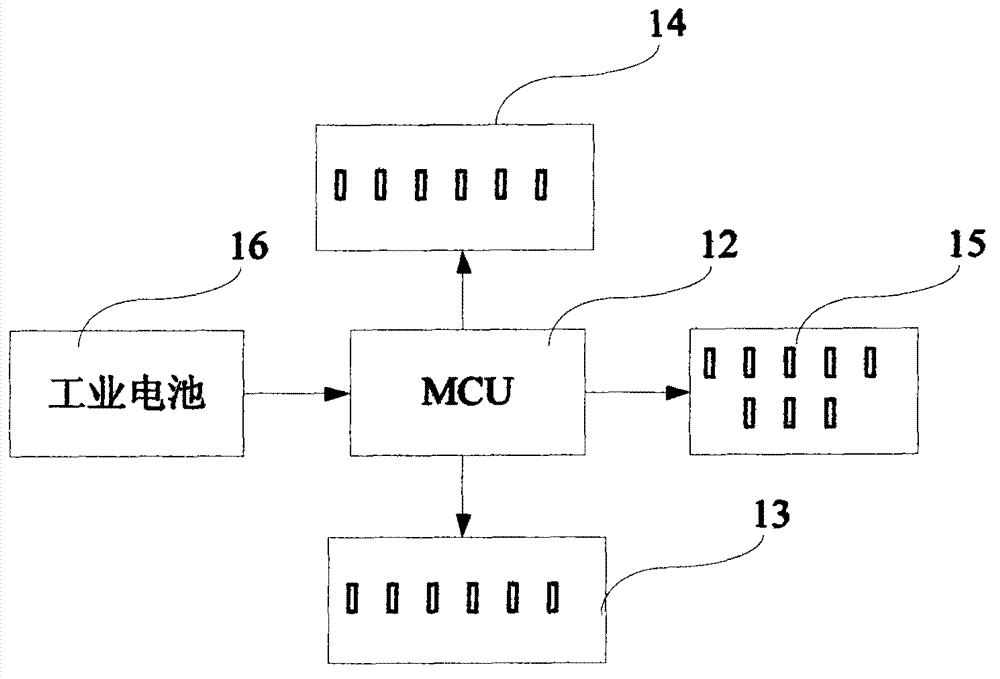

[0026] The sending and receiving process of the wireless blast furnace cooling water temperature difference online measurement system provided by the present invention is realized by using a high-performance and low-power radio frequency chip. The communication between the receiving (relay) and transmitting modules adopts a one-to-many method. Generally, one receiving (relay) site collects temperature data of multiple transmitting nodes.

[0027] The whole system works in the 2.4G or 433M frequency band, using IEEE802.15.4 / Zigbee or other low-power personal area network protocols. The system includes a network server, an industrial control computer, a data converter, multiple receiving (relay) sites and multiple transmitting nodes.

[0028] In order to avoid mutual interference between s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com