Light cured alkali resistant coating

A light-curing and alkali-resistant technology, used in anti-corrosion coatings, polyester coatings, polyether coatings, etc., can solve the problems of low degree of double bond reaction, accelerated hydrolysis of ester groups, and inability to solve the bottleneck of alkali resistance of films, and achieves improvement. Comprehensive anti-corrosion performance, strong alkali corrosion resistance, good anti-corrosion effect

Inactive Publication Date: 2013-01-02

SNTO TECH GRP

View PDF6 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

On the one hand, the main chain of the resin or monomer raw materials used in photocurable coatings is rich in ester groups, and the ester groups are prone to accelerated hydrolysis under alkaline conditions, thereby destroying the main chain structure of the coating film.

On the other hand, due to the characteristics of the photocuring technology itself, the rapid curing of the coating film can be achieved at room temperature, while the movement of molecular chains is limited at low temperatures, and the molecular chains cannot be fully fused and collided, resulting in the degree of reaction of double bonds. Not high, it is difficult to form a dense cross-linked network structure on the coating film

Chinese patent CN1014007650A on April 15, 2009 disclosed a UV-curable polyaniline anti-corrosion coating and its preparation method. The UV-curable polyaniline anti-corrosion coating uses polyaniline as the main anti-corrosion material. , polyaniline, fillers, photoinitiators, and additives are blended according to the ratio, stirred, ground, filtered, etc., to obtain a UV-curable polyaniline anti-corrosion coating, but the coating adopts a physical mixing method and cannot form a dense coating on the coating film. The cross-linked network structure cannot solve the alkali resistance bottleneck under the film

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0020]

Embodiment 2

[0022]

Embodiment 3

[0024]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

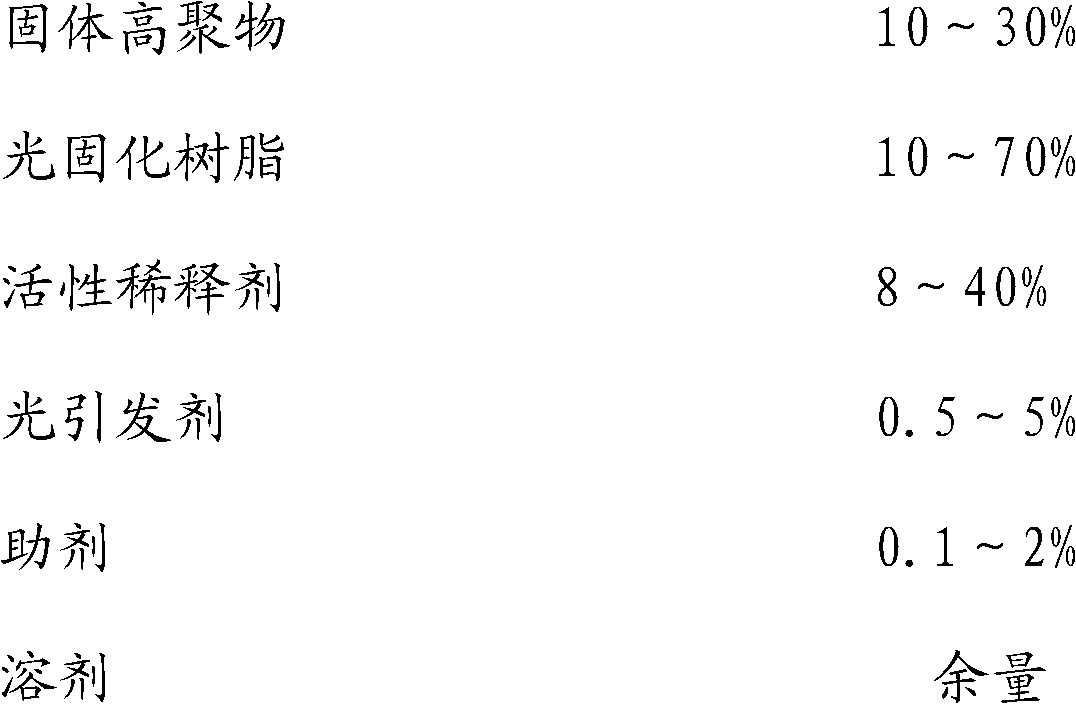

Login to View More Abstract

A light cured alkali resistant coating is prepared from (by wt%) solid high polymer 10-30, light curing resin 10-70, reactive diluent 8-40, photoinitiator 0.5-5, assistant 0.1-2, and solvent in balance. The invention introduces solid high polymer into preparation raw material of current UV-light cured coating, and on the basis of original frame of UV-light cured coating, utilizes network structure constructed by solid high polymer acrylate high molecular chain, to thereby improve comprehensive anti-corrosive property of light cured coating effectively, especially improve alkali resistance of coating under thin coating condition.

Description

technical field [0001] The invention belongs to the technical field of ultraviolet curing coatings, in particular to a photocuring alkali-resistant coating. Background technique [0002] Ultraviolet curing coatings (UV curing coatings) use the energy of ultraviolet light to initiate polymerization and crosslinking reactions between low-molecular prepolymers or oligomers in coatings and monomer molecules as reactive diluents to obtain hardened paint films. Compared with traditional natural drying or heat-curing coatings, light-curing coatings have high energy utilization rate, suitable for heat-sensitive substrates, no pollution, fast film-forming speed, high-quality coating film, suitable for continuous large-scale production And other characteristics, known as environmentally friendly coatings. [0003] Existing UV-curable coatings are usually composed of oligomers, reactive diluents, photoinitiators and additives. Oligomers are also called photosensitive resins and oligom...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D163/00C09D175/14C09D171/00C09D167/06C09D133/04C09D169/00C09D175/04C09D127/06C09D123/12C09D5/08

Inventor 梁勇

Owner SNTO TECH GRP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com