Mine polyethylene tube

A polyethylene pipe, high-density polyethylene technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of maximum pressure limit, poor low temperature resistance, no flame retardancy, etc., to achieve resistance Excellent flammability, good aging resistance, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

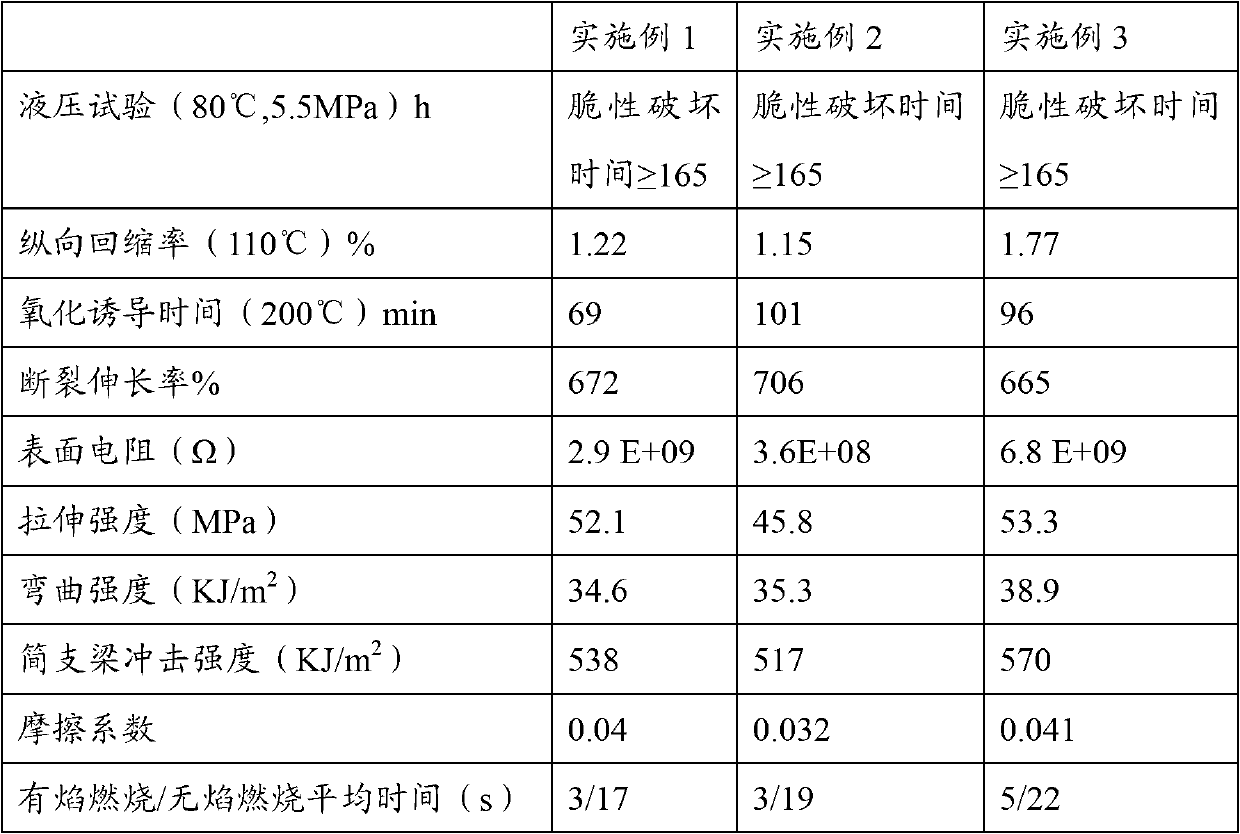

Embodiment 1

[0032] The mine-use polyethylene pipe of the present invention comprises the following components in parts by weight: 55 parts of high-density polyethylene, 10 parts of ethylene-propylene rubber, 10 parts of polypropylene, 10 parts of low-density polyethylene, 3 parts of lubricant, and 5 parts of compatibilizer, 2.0 parts of vulcanizing agent, 5 parts of flame retardant, 20 parts of carbon black.

[0033] Wherein, the melt index of the high-density polyethylene resin is 10g / 10min, and the density is 0.958g / cm 3 , an HDPE resin containing the following a) and b) components: a) a low molecular weight ethylene copolymer having a weight average molecular weight of 5,000 amu and a short chain branching index of 4.5; b) a weight average molecular weight of 60,000 amu and A high molecular weight ethylene copolymer with a short chain branching index of 1.5.

[0034] The ethylene-propylene rubber is EPDM rubber; the vulcanizing agent is dimorpholine disulfide;

[0035] The polypropyl...

Embodiment 2

[0047] The mine-use polyethylene pipe of the present invention comprises the following components by weight: the mine-use polyethylene pipe comprises the following components by weight: 75 parts of high-density polyethylene, 5 parts of ethylene-propylene rubber, polyethylene 8 parts of propylene, 5 parts of low density polyethylene, 8 parts of lubricant, 2 parts of compatibilizer, 1.0 part of vulcanizing agent, 8 parts of flame retardant, 15 parts of carbon black, 2 parts.

[0048] Wherein, the melt index of the high-density polyethylene resin is 5g / 10min, and the density is 0.960g / cm 3 , an HDPE resin containing the following a) and b) components: a) a low molecular weight ethylene copolymer having a weight average molecular weight of 50,000 amu and a short chain branching index of 3.5; b) having a weight average molecular weight of 800,000 amu and A high molecular weight ethylene copolymer with a short chain branching index of 2.5.

[0049] The ethylene-propylene rubber is ...

Embodiment 3

[0062] The mine-use polyethylene pipe of the present invention comprises the following components by weight: the mine-use polyethylene pipe comprises the following components by weight: 80 parts of high-density polyethylene, 10 parts of ethylene-propylene rubber, polyethylene 5 parts of propylene, 3 parts of low-density polyethylene, 5 parts of lubricant, 3 parts of compatibilizer, 0.1 part of vulcanizing agent, 6 parts of flame retardant, 10 parts of carbon black, and 1 part of sulfur.

[0063] Wherein, the melt index of the high-density polyethylene resin is 8g / 10min, and the density is 0.965g / cm 3 , an HDPE resin containing the following a) and b) components: a) a low molecular weight ethylene copolymer having a weight average molecular weight of 10,000 amu and a short chain branching index of 2.5; b) a weight average molecular weight of 800,000 amu and A high molecular weight ethylene copolymer with a short chain branching index of 1.6.

[0064] The ethylene-propylene rub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com