Anti-rutting additive

An anti-rutting additive and epoxy resin technology, applied in the field of anti-rutting additives, can solve the problems of threatening driving safety, water accumulation, affecting driving stability and comfort, etc., and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

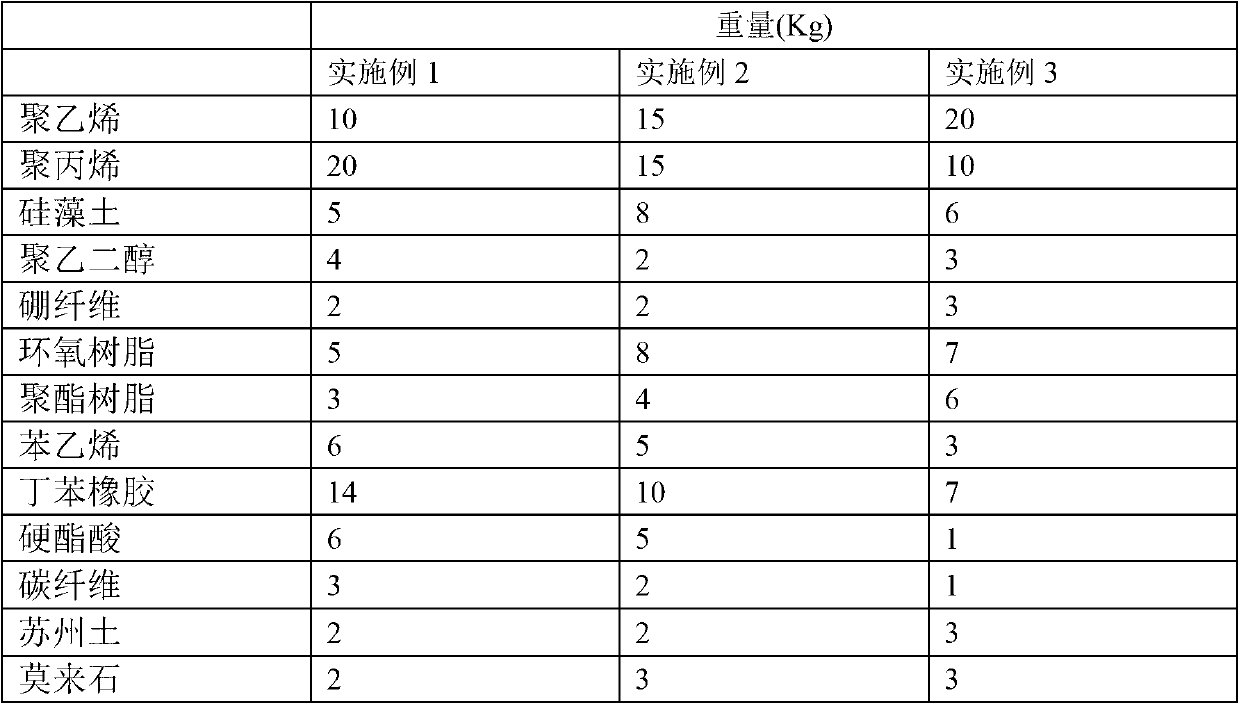

[0012] Get each component raw material by weight proportion in Table 1.

[0013] The weight proportion of table 1 embodiment 1~embodiment 3

[0014]

[0015] The molecular weight of the polyethylene mentioned above is 100,000-300,000.

[0016] The above-mentioned epoxy resin is a bisphenol A type epoxy resin.

[0017] The molecular weight of the above-mentioned polyethylene glycol is 20000-50000.

[0018] The preparation method of the above anti-rutting additive is: polyethylene, polypropylene, diatomaceous earth, polyethylene glycol, boron fiber, epoxy resin, polyester resin, styrene, styrene-butadiene rubber, stearic acid, carbon fiber, Suzhou Mix the soil and mullite evenly, and then put them into the single-screw extruder, set the heating temperature in the four zones to 150-160°C, 170-175°C, 175-180°C, 180-190°C, and adjust the screw speed to 35 rpm / min, extruded, granulated, that is.

[0019] When in use, the anti-rutting additive is added to conventional asphal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com