Cement-based perlite composite sound barrier

A perlite and composite sound technology, applied in noise absorption devices, buildings, etc., can solve the problems of slow project progress, high cost, long cycle, etc., and achieve the effect of improving compressive strength and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

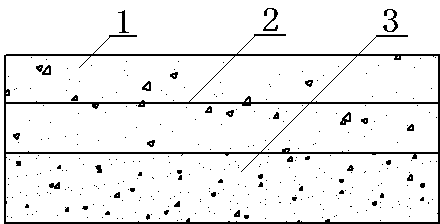

[0023] Embodiment one: from figure 1 It can be seen from the figure that a cement-based perlite composite sound barrier is composed of perlite layer 1 and ceramsite concrete layer 3, and is composed of perlite, glue, cement, water and yellow sand by weight 1:0.048:1.8:3.8:2.7 The ratio is mixed to form a perlite mixture, and the ceramsite, cement, water and yellow sand are mixed in a weight ratio of 2:1.8:3.8:2.7 to form a ceramsite concrete mixture. Then pour the perlite mixture into the mold and pave it, and finally add the ceramsite concrete mixture to pave it, press the whole mold under a certain pressure, and release the mold after maintaining the pressure. The thickness of the perlite layer 1 is 7cm, and the thickness of the ceramsite concrete layer 3 is 5.5cm; the particle size of the perlite is 3mm, and the particle size of the ceramsite is 20mm.

Embodiment 2

[0024] Embodiment 2: A cement-based perlite composite sound barrier, consisting of perlite layer 1 and ceramsite concrete layer 3, composed of perlite, glue, cement, water and yellow sand in a weight ratio of 1:0.05:2:4:3 Mix to form a perlite mixture, and mix ceramsite, cement, water and yellow sand in a weight ratio of 2:2:4:3 to form a ceramsite concrete mixture. Then pour the perlite mixture into the mold and pave it, and finally add the ceramsite concrete mixture to pave it, press the whole mold under a certain pressure, and release the mold after maintaining the pressure. The thickness of the perlite layer 1 is 8cm, and the thickness of the ceramsite concrete layer 3 is 6cm; the particle size of the perlite is 4mm, and the particle size of the ceramsite is 25mm.

Embodiment 3

[0025] Embodiment 3: A cement-based perlite composite sound barrier, consisting of perlite layer 1 and ceramsite concrete layer 3, composed of perlite, glue, cement, water and yellow sand in a weight ratio of 1:0.052:2.2:4.2:3.3 Mix to form a perlite mixture, and mix ceramsite, cement, water and yellow sand in a weight ratio of 2:2.2:4.2:3.3 to form a ceramsite concrete mixture. Then pour the perlite mixture into the mold and pave it, and finally add the ceramsite concrete mixture to pave it, press the whole mold under a certain pressure, and release the mold after maintaining the pressure. The thickness of the perlite layer 1 is 9cm, and the thickness of the ceramsite concrete layer 3 is 7cm; the particle size of the perlite is 5mm, and the particle size of the ceramsite is 30mm.

[0026] In order to improve the strength of the sound barrier, a steel mesh 2 is arranged in the perlite layer 1 .

[0027] In addition, surface spraying can be carried out according to customer re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com