Method for growing carbon film or inorganic material film on substrate

A material film and carbon film technology, which is applied in the field of direct growth of high-quality and wafer-sized graphene layers, which can solve problems such as difficulty in controlling thin-layer graphene and inability to form high-quality graphene.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

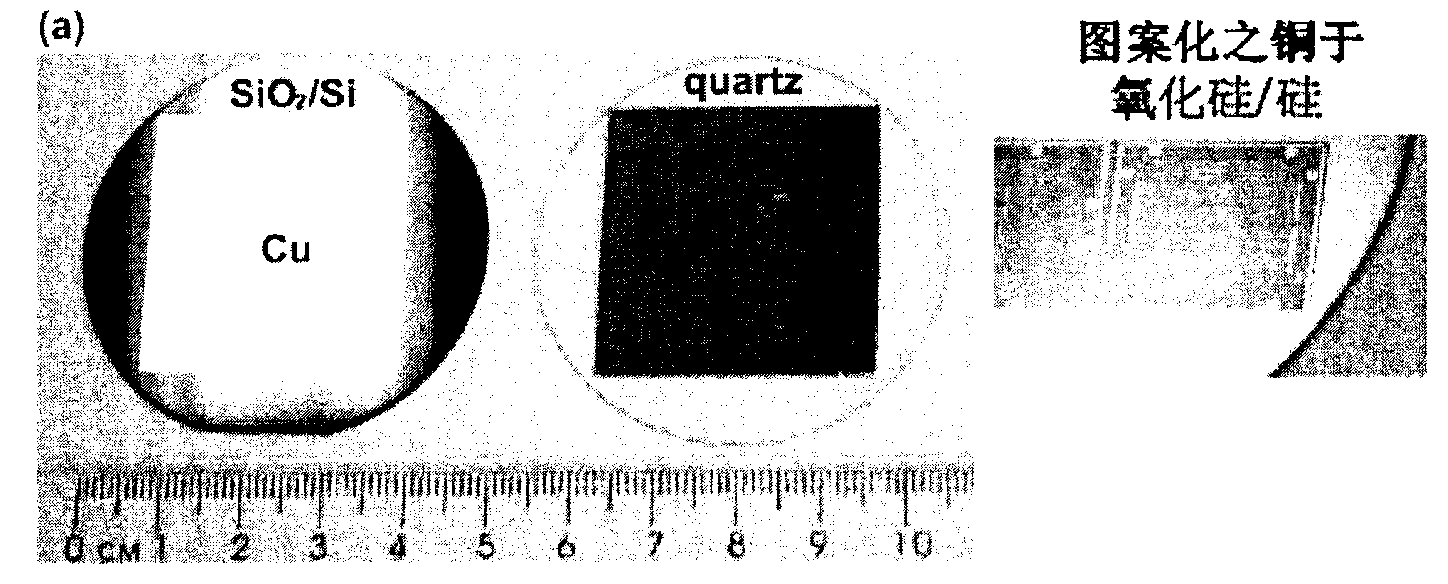

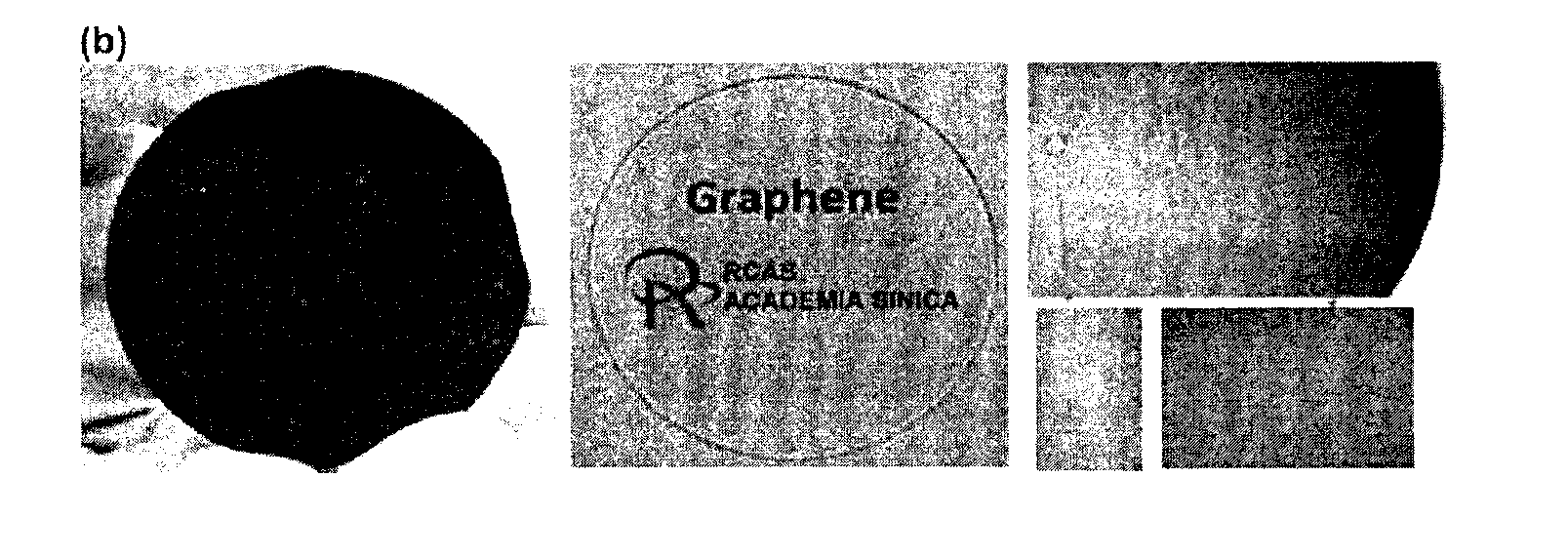

[0058] The known quartz tubular furnace is adjusted to a device suitable for synthesizing the underlying graphene layer, and the graphene layer is directly grown on the insulating substrate in the following manner:

[0059] A 300nm copper film is deposited on an insulating substrate, and then the insulating substrate is placed in the aforementioned quartz tube furnace. Then, methane is used as a carbon source, in a hydrogen atmosphere and at a pressure of 500 Torr, The insulating substrate was heated to 750°C, and then thermally annealed at the same temperature for 25 minutes. In a pure hydrogen environment (H 2 : 15 sccm; Pressure: 800 mTorr), and heat the furnace to 900°C. When the temperature reaches 900℃, the gas condition is changed to methane / hydrogen mixture (CH 4 =75sccm and H 2 = 15sccm) and under a pressure of 800 millitorr (mTorr) for 5 minutes. In the cooling stage, the furnace is cooled to room temperature at a rate of about 20° C. / min, while maintaining the same ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com