Preparation method of batch preparation of boron nitride nanotube

A boron nitride nanotube, batch technology, applied in chemical instruments and methods, nitrogen compounds, nanotechnology and other directions, can solve the problems that restrict the wide application of boron nitride nanotubes, high preparation temperature, complex process, etc., and achieve a wide range of industrial applications. The effect of application value, simple preparation process and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

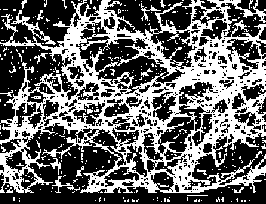

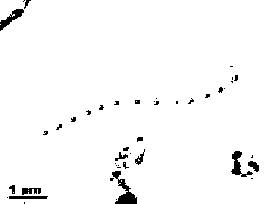

[0022] 称取5克无定形B粉,1.45克Fe 2 o 3 ,1.27克CaO,充分混合后平铺在氧化铝瓷板上,置于管式炉内,充入氩气保护并开始升温,氩气流量为300ml / min,升温至1000℃时,停止通入氩气,开始通入NH 3 , NH 3 流量为150ml / min,并继续加热至1300℃,保温4个小时,保温结束后停止通入任何气体,关闭管式炉进、出气口,自然降温至室温,得到白色粗产物,将粗产物在空气中加热至600℃进行氧化处理,将氧化后的粗产物放入浓度为38wt%的盐酸中浸泡6小时,抽滤,洗涤,干燥后可得到9.9克BN纳米管粉体,以B粉为基准计算其产率为87%,BN纳米管的纯度约为90%,所制备出的氮化硼纳米管为多壁纳米管,平均管径为150nm,长度大于100微米,管身均匀光滑。

Embodiment 2

[0024] 称取7克B 2 o 3 ,0.42克Co 2 o 3 ,0.78克BaO,充分混合后平铺在氧化铝瓷板上,置于管式炉内,充入氩气保护并开始升温,氩气流量为300ml / min,升温至1100℃时,停止通入氩气,开始通入NH 3 , NH 3 流量为200ml / min,并继续加热至1400℃,保温3个小时,保温结束后停止通入任何气体,关闭管式炉进、出气口,自然降温至室温,得到白色粗产物,将粗产物在空气中加热至600℃进行氧化处理,将氧化后的粗产物放入浓度为36wt%的盐酸中浸泡12小时,抽滤,洗涤,干燥后可得到4.3克BN纳米管粉体,以B 2 o 3 粉为基准计算其产率为85%,BN纳米管的纯度约为85%,所制备出的氮化硼纳米管为多壁纳米管,平均管径为180nm,长度大于100微米,管身均匀 smooth.

Embodiment 3

[0026] 称取6.2克H 3 BO 3 ,0.4克Fe 2 o 3 ,1.48克Ca(OH) 2 ,充分混合后平铺在氧化铝瓷板上,置于管式炉内,充入氩气保护并开始升温,氩气流量为500ml / min,升温至1000℃时,停止通入氩气,开始通入NH 3 , NH 3 流量为300ml / min,并继续加热至1200℃,保温4个小时,保温结束后停止通入任何气体,关闭管式炉进、出气口,自然降温至室温,得到白色粗产物,将粗产物在空气中加热至600℃进行氧化处理,将氧化后的粗产物放入浓度为37wt%的盐酸中浸泡8小时,抽滤,洗涤,干燥后可得到2.2克BN纳米管粉体,以H 3 BO 3 粉为基准计算其产率为88%,BN纳米管的纯度约为85%,所制备出的氮化硼纳米管为多壁纳米管,平均管径为120nm,长度大于100微米,管身均匀 smooth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com