Blast furnace slag micro powder compound type vortex superfine separator

A technology of blast furnace slag micropowder and separator, which is applied to the separation of solids from solids by air flow, solids separation, chemical instruments and methods, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

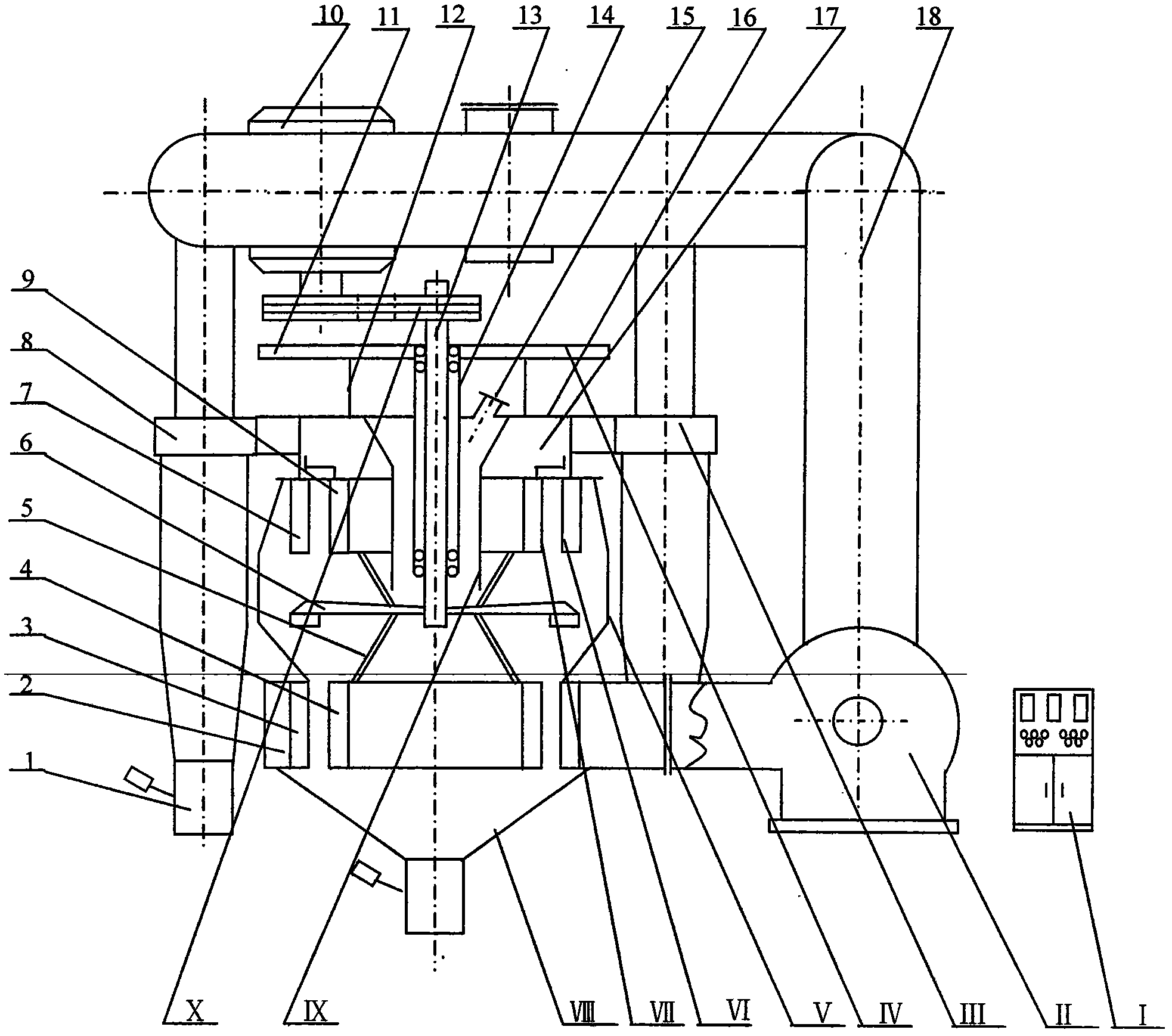

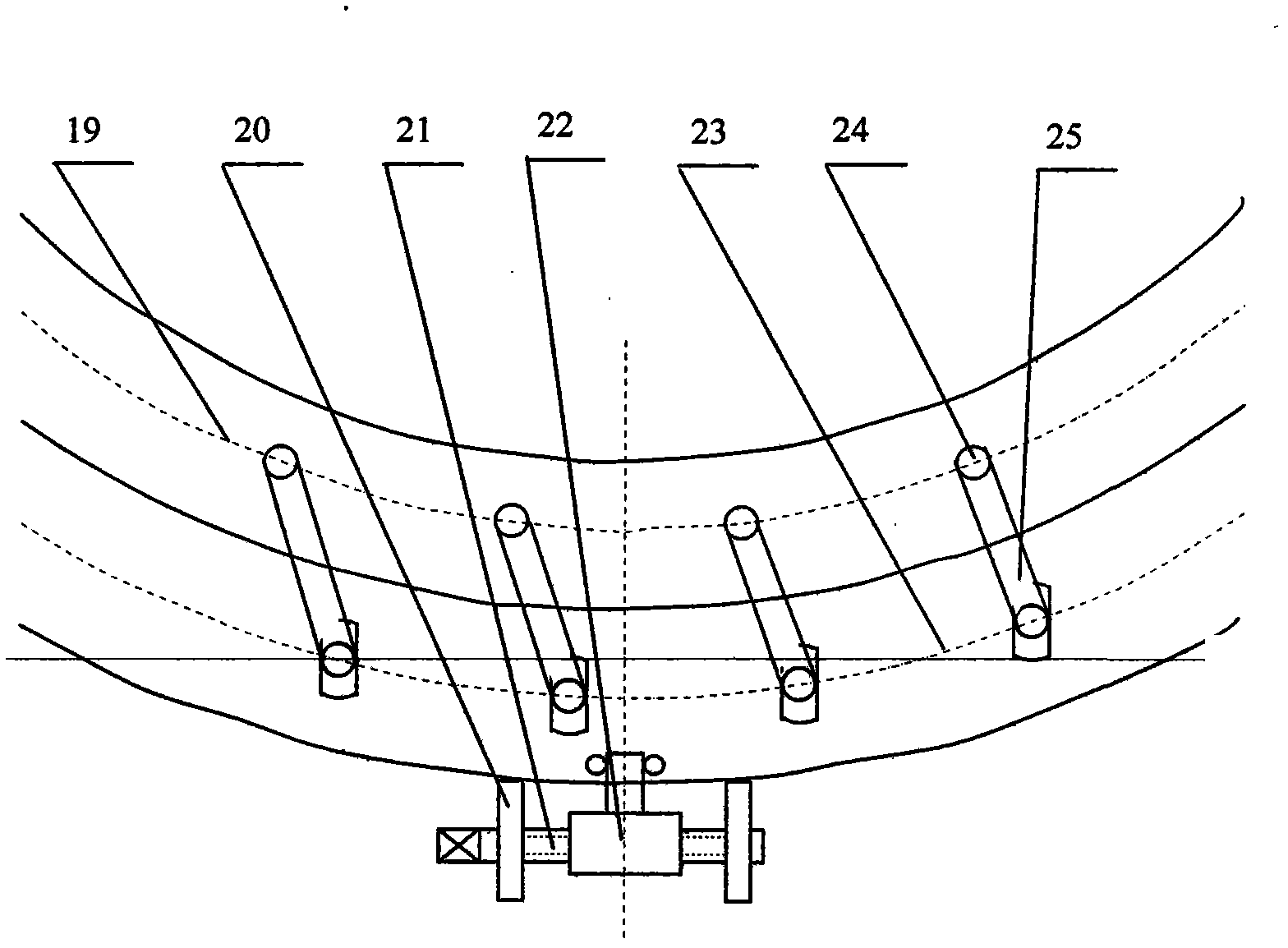

[0036] as attached figure 1 As shown, the blast furnace slag micropowder compound eddy current ultrafine separator of the present invention comprises a load-bearing installation base frame (Ⅸ), a feeding barrel (Ⅸ), a power transmission device (Ⅹ), a flow guiding device (Ⅵ), a micropowder separation device ( Ⅶ), fine powder separation device (Ⅲ), sorter housing (Ⅴ), air blowing and returning air device (Ⅱ), leftover powder storage device (Ⅷ), operation control box (Ⅰ).

[0037] as attached figure 1 As shown, the load-bearing installation base frame (IV) includes a well-shaped load-bearing beam (11), a horizontal reference connecting plate (16), a connection fixing seat (12), and a mounting bracket, which are welded and fixed into a rigid whole by welding , installed and fixed on the equipment foundation of the sorting machine through the installation bracket; the feeding cylinder (Ⅸ), the drive shaft sleeve (14), and the vortex powder collection chamber (17) are all verticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com