Preliminary gas distributor for fluidized bed reactor

The technology of a gas pre-distributor and a fluidized bed reactor is applied in the improvement field of the fluidized bed reactor technology, and can solve the problems of unguaranteed gas flow uniformity, reduced inlet effect, large flow rate, etc. Reduced import effects, improved uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

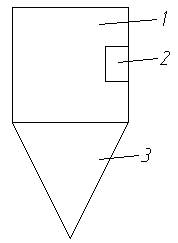

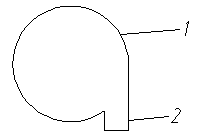

[0030] Such as figure 1 As shown, the gas pre-distributor of the fluidized bed reactor includes a gas inlet tangential to the gas pre-distributor and a conical structure below the pre-distributor. For a reactor with an inner diameter of 150mm, the optimized structure of the gas predistributor is selected: the gas inlet is rectangular, the length is 50mm, the width is 30mm, the ratio of length to width is 5:3, and the length and bed diameter (gas predistributor diameter) ratio of 1:3, the square inlet is located in the middle of the height of the pre-distributor. The conical structure is 150mm high and its height to bed diameter ratio is 1:1.

Embodiment 2

[0032] In a gas-solid fluidized bed reactor with a diameter of 1500 mm, air is used as the fluidizing gas, and the apparent operating gas velocity of the fluidized bed is 0.1 m / s, and the COMSOL simulation calculation software is used for simulation. The structural form of the gas pre-distributor is as follows: figure 1 , where the tangential square inlet is located in the middle of the height of the pre-distributor, the length is 500mm, and the width is 300mm; the height of the conical structure is 1500mm, and the diameter is 1500mm.

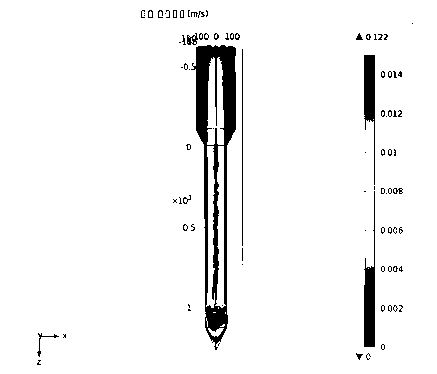

[0033] image 3 It is the velocity nephogram of the whole bed body of embodiment 2; Figure 4 Be embodiment 2 predistributor internal distribution plate lower surface cross-sectional velocity nephogram; Figure 5 It is the cloud diagram of the cross-sectional velocity on the upper surface of the distribution plate in Example 2. It can be seen from the figure that the gas velocity distribution in the whole bed is relatively uniform, all the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com