All-solid-state battery

An all-solid-state battery, solid electrolyte technology, applied in lithium batteries, battery electrodes, secondary batteries, etc., can solve problems such as electrolyte leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

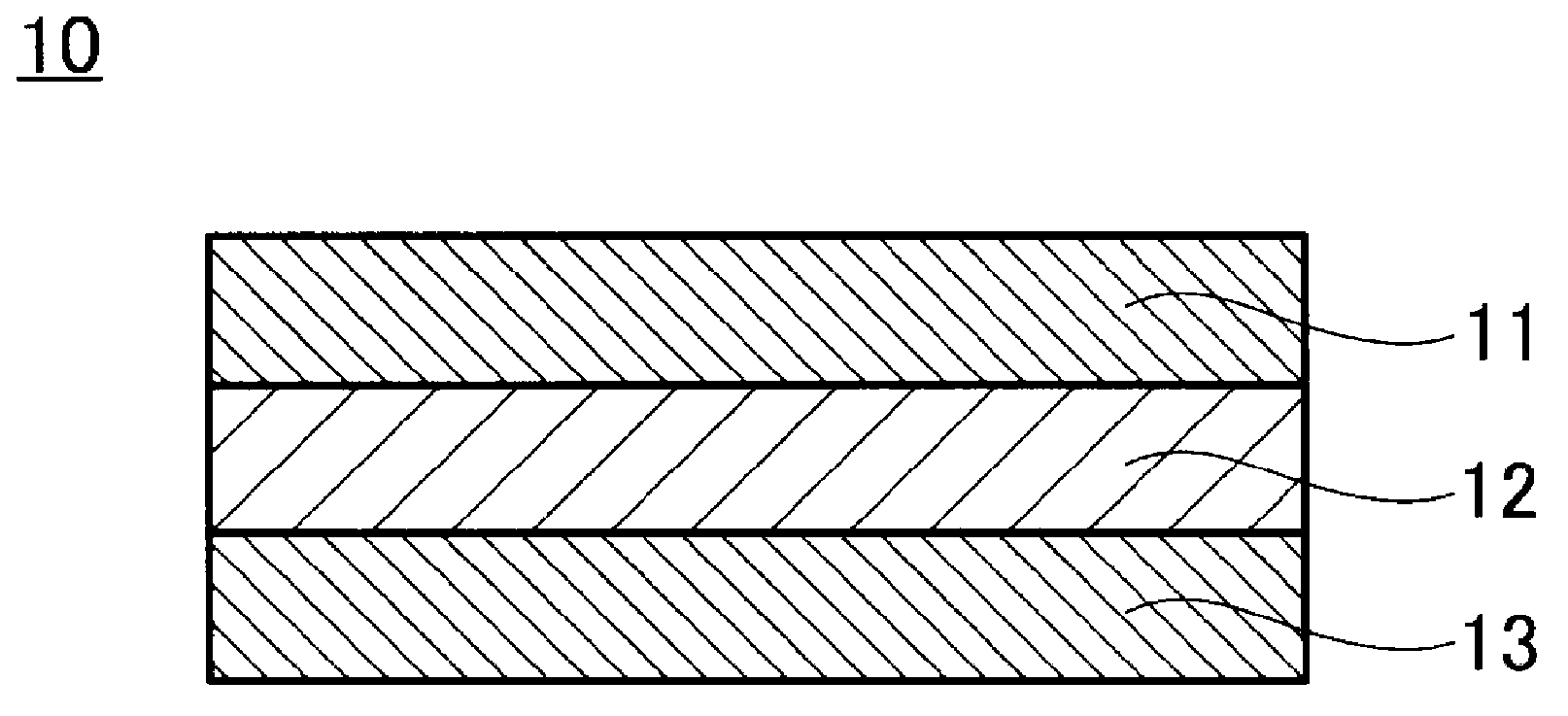

Image

Examples

Embodiment 1)

[0048]

[0049] First, in order to produce an all-solid-state battery, an electrode layer sheet and a solid electrolyte layer sheet were produced as follows.

[0050] First, anatase-type titanium oxide (TiO 2 ) powder, as a solid electrolyte, Li 1.5 Al 0.5 Ge 1.5 (PO 4 ) 3 (hereinafter referred to as "LAGP") glass powder.

[0051] Next, the anatase-type titanium oxide powder and the binder solution were mixed to prepare an electrode active material slurry. In addition, LAGP glass powder was mixed with a binder solution to make a solid electrolyte slurry. Carbon powder was also mixed with a binder solution to create a carbon paste. In addition, the binder solution is prepared by dissolving polyvinyl alcohol in an organic solvent.

[0052] The obtained electrode active material slurry, solid electrolyte slurry, and carbon slurry were mixed to prepare electrode layer slurry. The mixing ratio between LAGP glass powder, anatase-type titanium oxide powder and carbon powde...

Embodiment 2)

[0068] In embodiment 2, used brookite type titanium oxide (TiO 2 ) to replace the anatase-type titanium oxide used as the electrode active material in Example 1. Other manufacturing conditions are the same as in Example 1, thus an all-solid-state battery is manufactured.

[0069]

[0070] 50μA / cm in the voltage range of 1.0~3.0V 2 The obtained all-solid-state battery was charged and discharged at a constant current and a constant voltage at a current density. As a result, it was confirmed that the discharge capacity was about 100 mAh / g, charge and discharge were possible, and the battery exhibited the same level of capacity as a battery using an electrolytic solution.

Embodiment 3)

[0072] In embodiment 3, used molybdenum dioxide (MoO 2 ) powder to replace the anatase titanium oxide (TiO 2 ). Other manufacturing conditions are the same as in Example 1, thus an all-solid-state battery is manufactured.

[0073]

[0074] 50μA / cm in the voltage range of 1.0~3.0V 2 The obtained all-solid-state battery was charged and discharged at a constant current and a constant voltage at a current density. As a result, it was confirmed that the discharge capacity was about 200 mAh / g, and it was possible to charge and discharge, showing a capacity equivalent to that of a battery using an electrolytic solution.

[0075] In addition, in the voltage range of 1.4 ~ 3.0V at 50μA / cm 2 The obtained all-solid-state battery was charged and discharged at a constant current and a constant voltage at a current density. As a result, the discharge capacity in the first cycle was 200 mAh / g, the discharge capacity in the fifth cycle was 198 mAh / g, and the cycle efficiency was 99%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| cycle efficiency | aaaaa | aaaaa |

| cycle efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com