Method for realizing all-fiber package of semiconductor saturable absorption mirror

A saturable absorption and semiconductor technology, applied in the direction of lasers, laser components, electrical components, etc., can solve the problems of complex structure, low price, and high price, and achieve the effect of good repeatability, simple operation, and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific example the present invention will be further described:

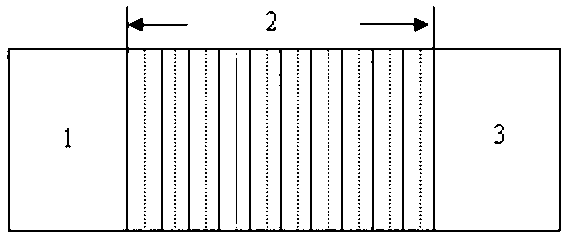

[0028] figure 1 Shown are the structure and plan views of the unpackaged semiconductor saturable absorber mirror 4 . Such as figure 1 As shown, an unpackaged semiconductor saturable absorbing mirror 4 is made of gallium arsenide substrate 1, and several layers of aluminum arsenide and gallium arsenide or aluminum arsenide potassium and aluminum arsenide are alternately grown. The effect is similar to that of a Bragg reflection grating mirror 2 and a semiconductor saturable absorber 3 composed of a multi-quantum well structure.

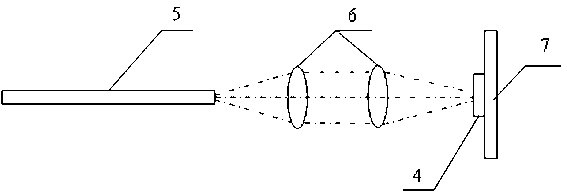

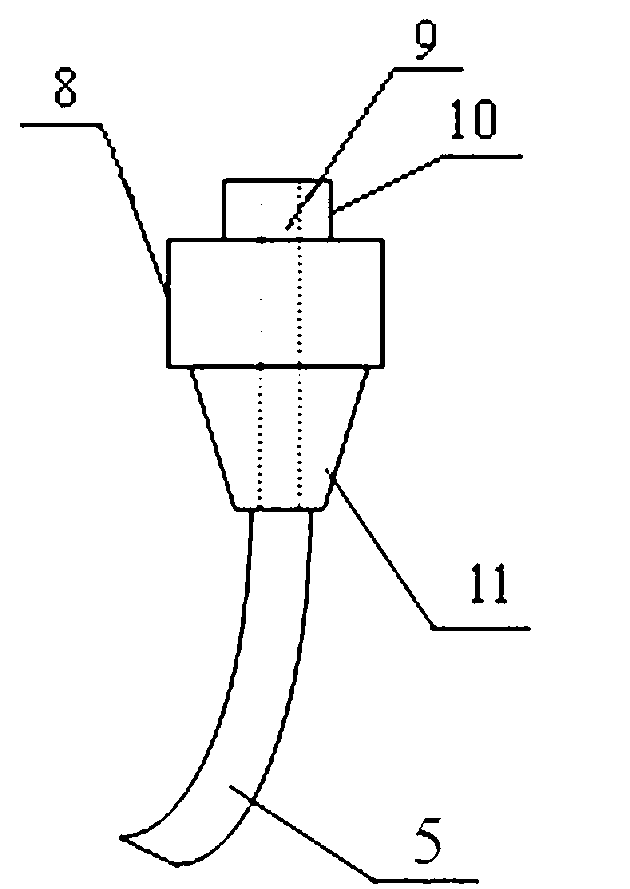

[0029] figure 2 Shown is a schematic diagram of the coupling system of a semiconductor saturable absorbing mirror packaged with a copper base and an optical fiber. Such as figure 2 As shown, the semiconductor saturable absorbing mirror 4 is pasted on the copper base 7, and the copper base 7 and the optical fiber 5 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com