Method and equipment for forming electric core tab

A forming method and tab technology, applied in the direction of circuits, electrical components, battery components, etc., can solve the problems of complicated procedures and low process efficiency, achieve low requirements for winding precision, improve process efficiency, and ensure process quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

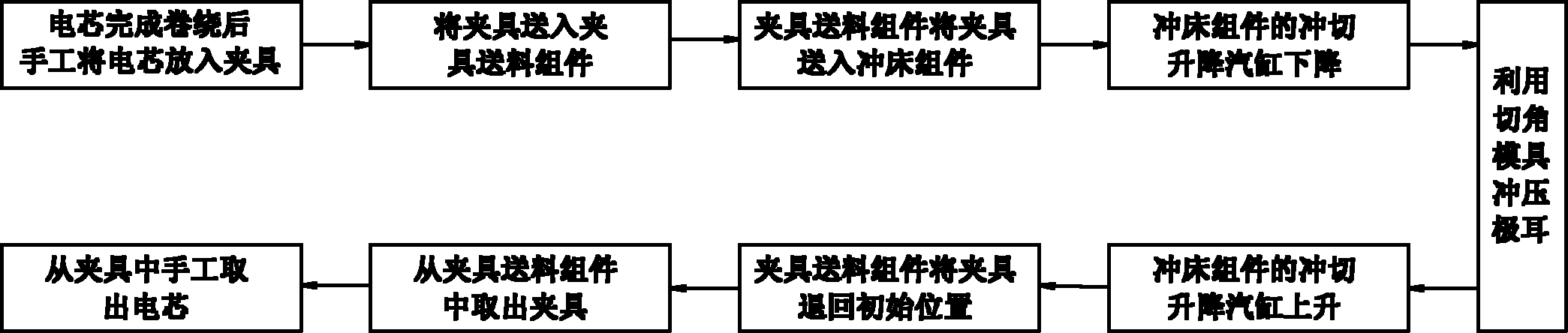

[0044] The present invention provides a method for forming battery tabs and equipment for realizing the method. The method mainly replaces the tab welding machine or laser cutting machine in the prior art to process the tabs on a single pole piece into a certain shape. Then the technical solution of making the processed and formed tabs directly into the battery core in the winding machine, but first adopting the initial shape of the tab (the tab that is not cut and formed by a tab welding machine or a laser cutting machine) The battery core is wound on the winding machine. After the winding is completed, the forming equipment is used to punch and form the tabs on the wound battery core.

[0045] Such as figure 1 As shown, the forming method of the battery tab of an embodiment includes the following steps:

[0046] After the batt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com