Optimal design method for parameter of controllable cylinder type hydraulic buffer of semi-active suspension

A technology of semi-active suspension and hydraulic shock absorber, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc. , reliable design method, lack of accurate design mathematical model of shock absorber valve parameters, etc., to avoid repeated tests and modifications, shorten the development cycle, and achieve accurate and reliable design values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

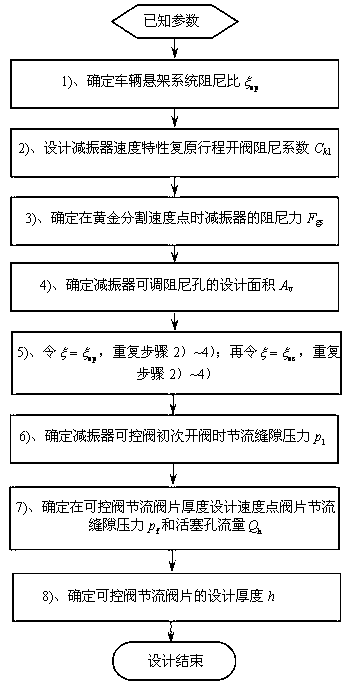

[0032] The present invention will be further described in detail through an embodiment below.

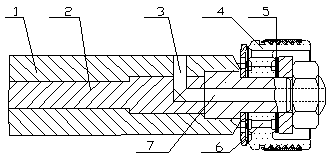

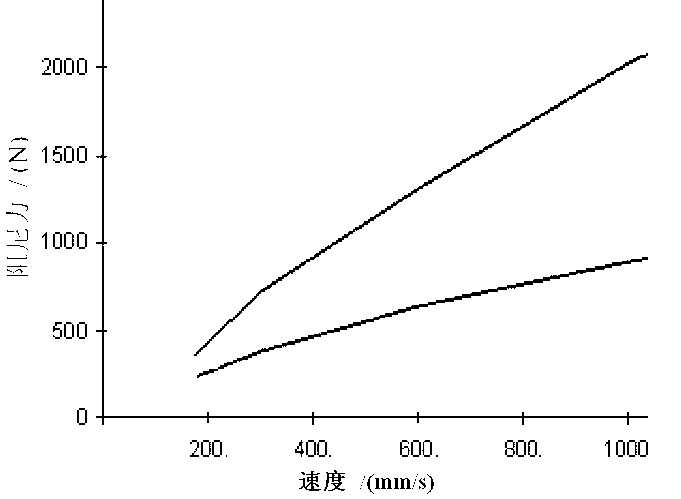

[0033] The sprung mass of an automobile suspension system m 2 =445kg; unsprung mass m 1 =38kg; suspension spring stiffness K =29679N / m and tire stiffness K t =267112N / m; shock absorber installation leverage ratio i =0.95; shock absorber installation angle θ =5°; the annular area between the piston cylinder and the piston rodS r =3.02×10 -4 m 2 ;Cylinder inner diameter D H =28mm; piston gap length L H =9mm; Piston average clearance δ H =0.04mm; eccentricity e =1.0; oil dynamic viscosity mu t =8.9×10 -3 m 2 Ps; oil density ρ =0.89×10 3 kg / m 3 ;Number of piston holes n h =4; piston hole diameter d h =2mm; equivalent length of piston hole L he =5mm; normally open orifice area A 0 =0.2mm 2 ;Normally throttling orifice flow coefficient ε 0 =0.82; adjustable damping orifice flow coefficient ε v =0.82; equivalent length of piston rod hole L ge =30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com