Tower node connection device made from composite material

A composite material and node connection technology, applied in towers, building types, buildings, etc., can solve problems such as the impact of insulation performance, achieve safe and reliable performance, simple installation and use methods, and improve the effect of lightning protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with example the present invention is described in detail.

[0035] The purpose of the present invention is to provide a full composite connection technology for composite material towers, which is used to solve the problem of unsatisfactory insulation performance of existing metal flange connection structures, and achieve the purpose of improving the insulation performance of composite material towers.

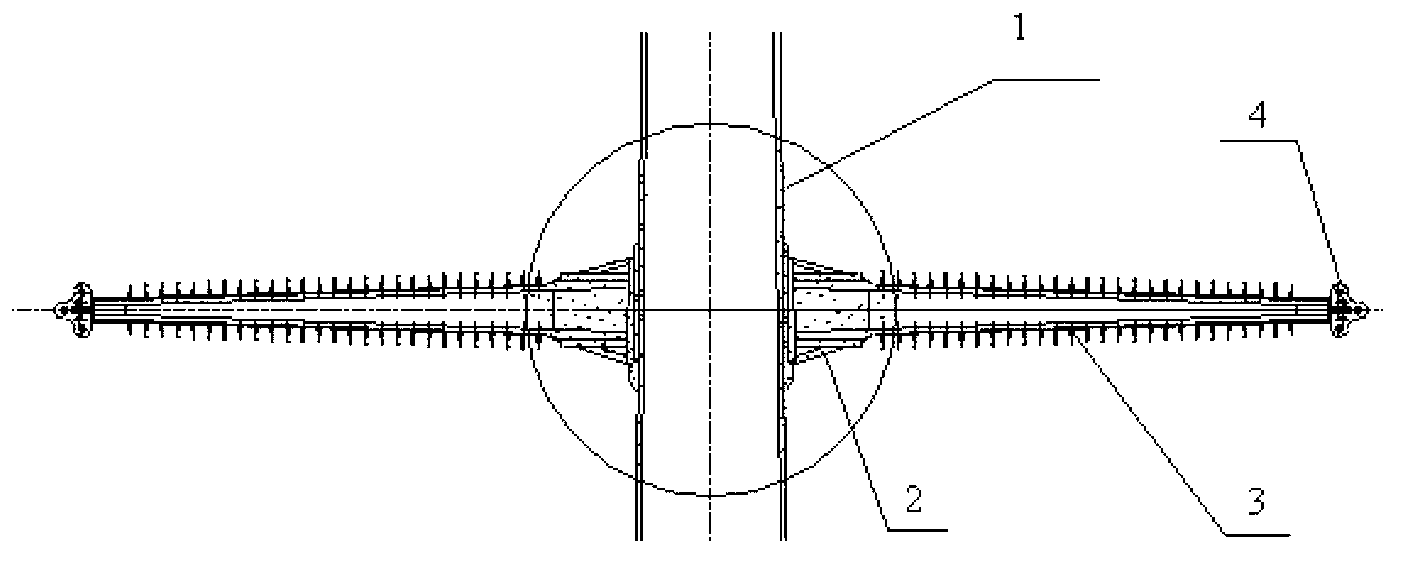

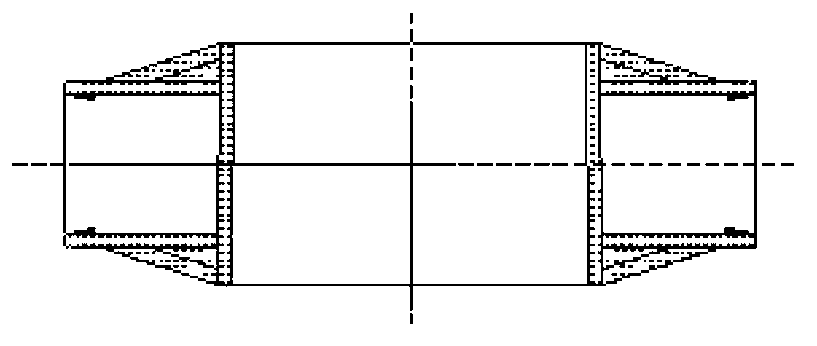

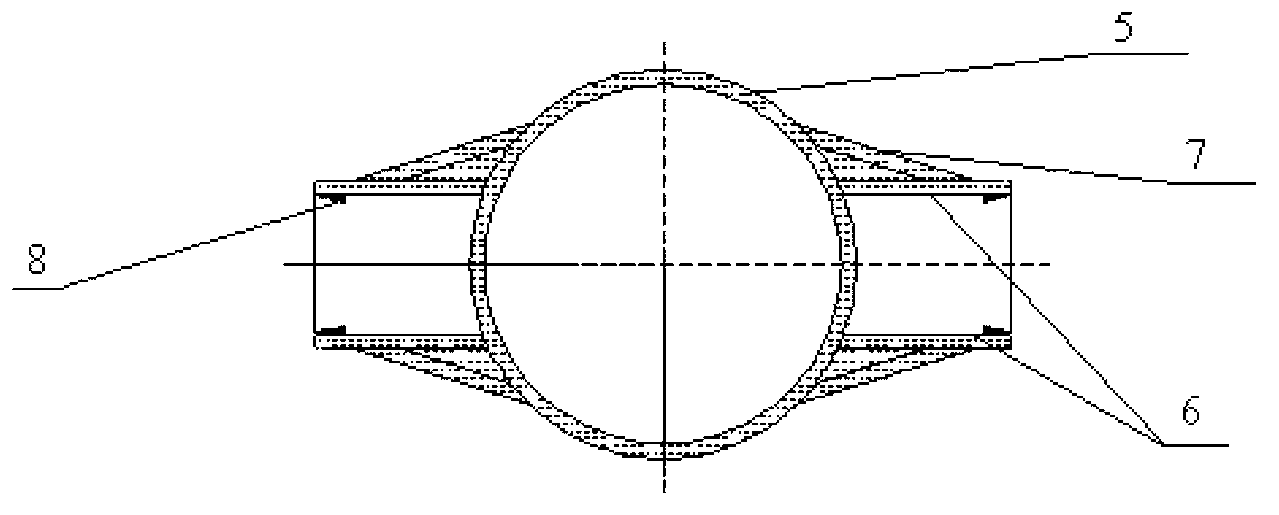

[0036] The invention provides an all-composite material connection device, which includes: a main rod 1 , a cross arm 3 and a node hoop 2 . The main rod 1 adopts a composite material winding structure, and the whole adopts the tipping form. After the main rod 1 is cured at room temperature as a whole, it is post-processed at a medium temperature, and is machined at the connection between the large end and the hoop 2 area of the cross arm 3, and the small end head position, an arched top cap is set to prevent rainwater from entering; the cross arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com