Cement-based fiber-reinforced fireproof heat-preservation plate and preparation process thereof

A fire-proof insulation board, fiber-reinforced technology, applied in the direction of heat preservation, fire prevention, building components, etc., can solve the problems of inability to mass-produce industrial production, failing to meet A-level fire protection standards, complex production processes, etc. Compliant with fire-resistant integrity and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

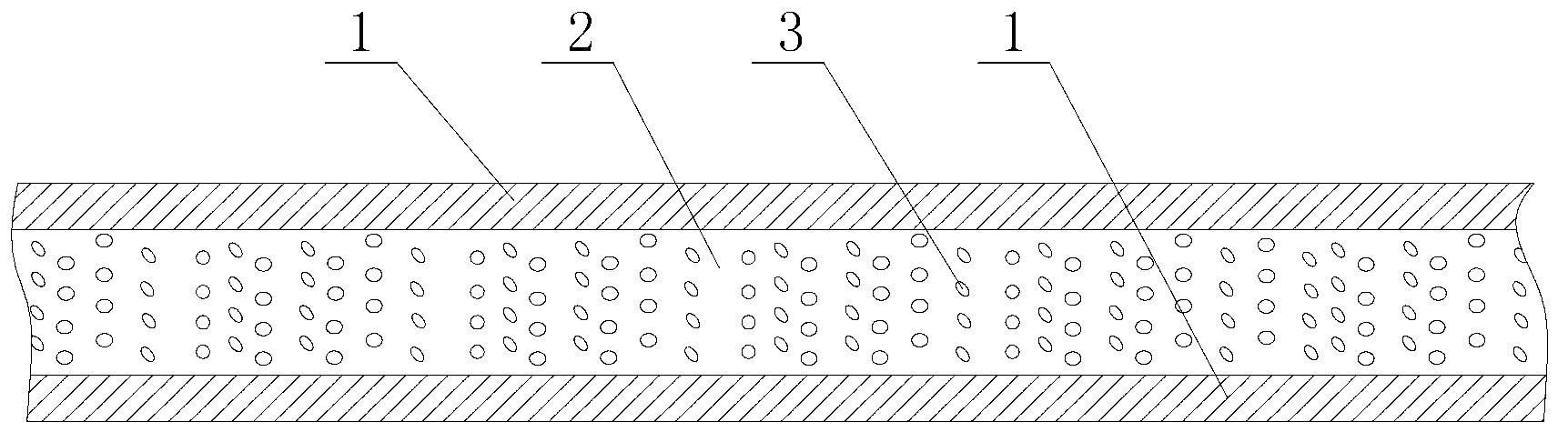

[0024] Such as figure 1 As shown, a cement-based fiber-reinforced fireproof insulation board includes a core layer, the upper and lower surfaces of the core layer are respectively provided with surface layers 1, and the core layer is a cement gelled layer 2.

[0025] In this embodiment, the cement gel layer 2 contains unevenly distributed expanded particles 3 . The expanded particles 3 are EPS foam particles, and the surface layer 1 is mesh cloth.

[0026] The cement gel layer in this embodiment includes the following components: cement, EPS foam particles, fiber cloth, bentonite, light calcium, glass water, water, foaming agent and latex. The above-mentioned raw materials will not burn at high temperatures and will not release toxic gases. They are safe and environmentally friendly materials, and all the raw materials used come from nature without any corrosiveness and radioactivity.

[0027] In the present invention, the mass percentages of cement, EPS foam particles, fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com