Preparation method of high purity ramoplanin single components

A single-component, filter aid technology, which is applied in peptide preparation methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of large damage to downstream purification media, inability to realize large-scale production, and decline in silica gel chromatography. , achieve the effects of shortening the process cycle, guaranteeing safety technology, and reducing solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

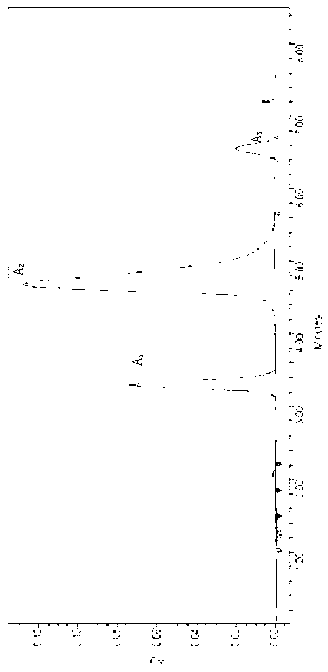

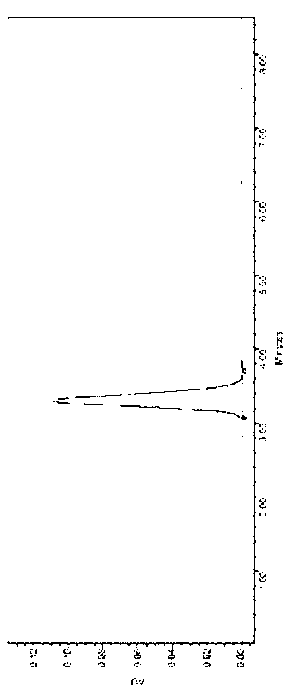

[0037] Take 10L of remoplanin fermentation broth, the fermentation unit is 1036μg / mL (calculated as A1+A2+A3), containing 1.55g of A1, 8.08g of A2, and 0.73g of A3. Add 100g of perlite to the fermentation broth at room temperature, stir for 50 minutes, and then filter the plate and frame. The filtrate passes through the macroporous resin D290 column at a flow rate of 1-2BV / h for decolorization, and the decolorization solution is introduced into the macroporous resin D312 column at a flow rate of 1BV / h Carry out adsorption enrichment, after adsorption, use 30% ethanol / water solution and 60% ethanol / water solution for discontinuous gradient desorption, the desorption flow rate is controlled at 0.5BV / h, when HPLC detects that remoplanin flows out, start to collect the desorption liquid, desorption is complete Finally, the stripping solution was concentrated in vacuum at 30°C to a remoplanin concentration of 100g / L-120g / L to obtain a crude extract (see figure 1) 19.2g (51.6% cont...

Embodiment 2

[0039] Take 100L of remoplanin fermentation broth, the fermentation unit is 1137μg / mL (calculated as A1+A2+A3), containing 15.92g of A1, 89.82g of A2, and 7.96g of A3. Add 3Kg of diatomaceous earth to the fermentation broth at room temperature, stir for 90 minutes, and then filter the plate and frame. The filtrate passes through the macroporous resin LX-700 column at a flow rate of 1.5BV / h for decolorization, and the decolorization solution is introduced at a flow rate of 1.5BV / h The macroporous resin HZ816 column is used for adsorption and enrichment. After adsorption, it is desorbed with a discontinuous gradient of 40% methanol / water solution and 60% methanol / water solution. The desorption flow rate is controlled at 0.5BV / h. When HPLC detects that remoplanin flows out, it starts to collect The desorption solution, after the desorption is completed, was concentrated in vacuum at 40°C to a remoplanin concentration of 110g / L-120g / L in the desorption solution to obtain 210.8g of ...

Embodiment 3

[0041] Take 1000L of remoplanin fermentation broth, the fermentation unit is 1058μg / mL (calculated as A1+A2+A3), containing 148.12g of A1, 825.24g of A2, and 84.64g of A3. Add 100Kg of perlite to the fermentation broth at room temperature, stir for 90 minutes, and then filter the plate and frame. The filtrate passes through the macroporous resin LX-700 column at a flow rate of 1.5BV / h for decolorization, and the decolorization solution is introduced into the macropore at a flow rate of 1.5BV / h Resin D312 column for adsorption and enrichment, after adsorption, use 30% ethanol / water solution and 60% ethanol / water solution for discontinuous gradient desorption, the desorption flow rate is controlled at 0.5BV / h-1BV / h, and when remoplanin flows out as detected by HPLC Start to collect the desorption liquid. After the desorption is completed, the desorption liquid is vacuum concentrated at 50°C to a remoplanin concentration of 110g / L-120g / L to obtain 1978.5g of crude extract (50.8% c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com