Antenna substrate material using spinel ferrite as matrix and preparation method thereof

A spinel ferrite, antenna substrate technology, applied in the field of composite substrate materials, can solve the problems of poor application effect, large magnetic loss, rising to more than 0.05, etc., and achieves reduction in size and volume, magnetic loss and dielectric loss. The effect of low electrical loss and low loss characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is a specific embodiment of the antenna substrate material of the present invention.

[0024] The formula molecular formula of the ferrite phase in the composite ceramic material is Mg 0.8 Cu 0.1 Zn 0.05 co 0.05 Fe 1.96 o 4-δ , the molecular formula of zinc silicate is Zn 0.8 SiO 3.8 .

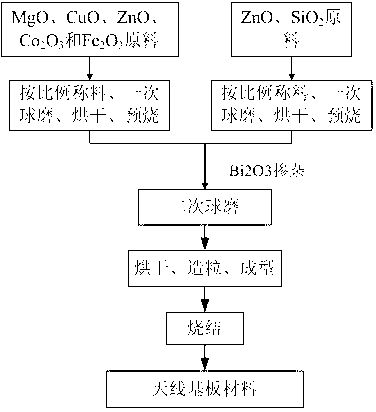

[0025] like figure 1 Shown, the concrete preparation method of this material is as follows:

[0026] Step 1: Fe 2 o 3 , MgO, ZnO, CuO and Co 2 o 3 As the raw material, convert the mass percentage of various oxides according to the ratio of metal elements in the above ferrite formula molecular formula. After accurate weighing, ball mill in a planetary ball mill for 4 hours at a time. After ball milling, the material is placed in an oven at 100 Dry at ℃.

[0027] Step 2: After sieving the dried material obtained in Step 1, compact and drill holes in the sintering bowl, heat up to 900°C for pre-burning at a rate of 3°C / min, keep it warm for 2 hours, and cool dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com