Cage-shaped filler type device for treating beer waste water in anaerobic-anoxic-aerobic mode and method for treating bear waste water by using device

A beer wastewater and aerobic treatment technology, applied in the field of reactors, can solve the problems of deterioration of effluent water quality and difficulty in obtaining good treatment effects by ABR, and achieve the effects of low treatment and construction costs, simple structure, and prevention of sludge loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

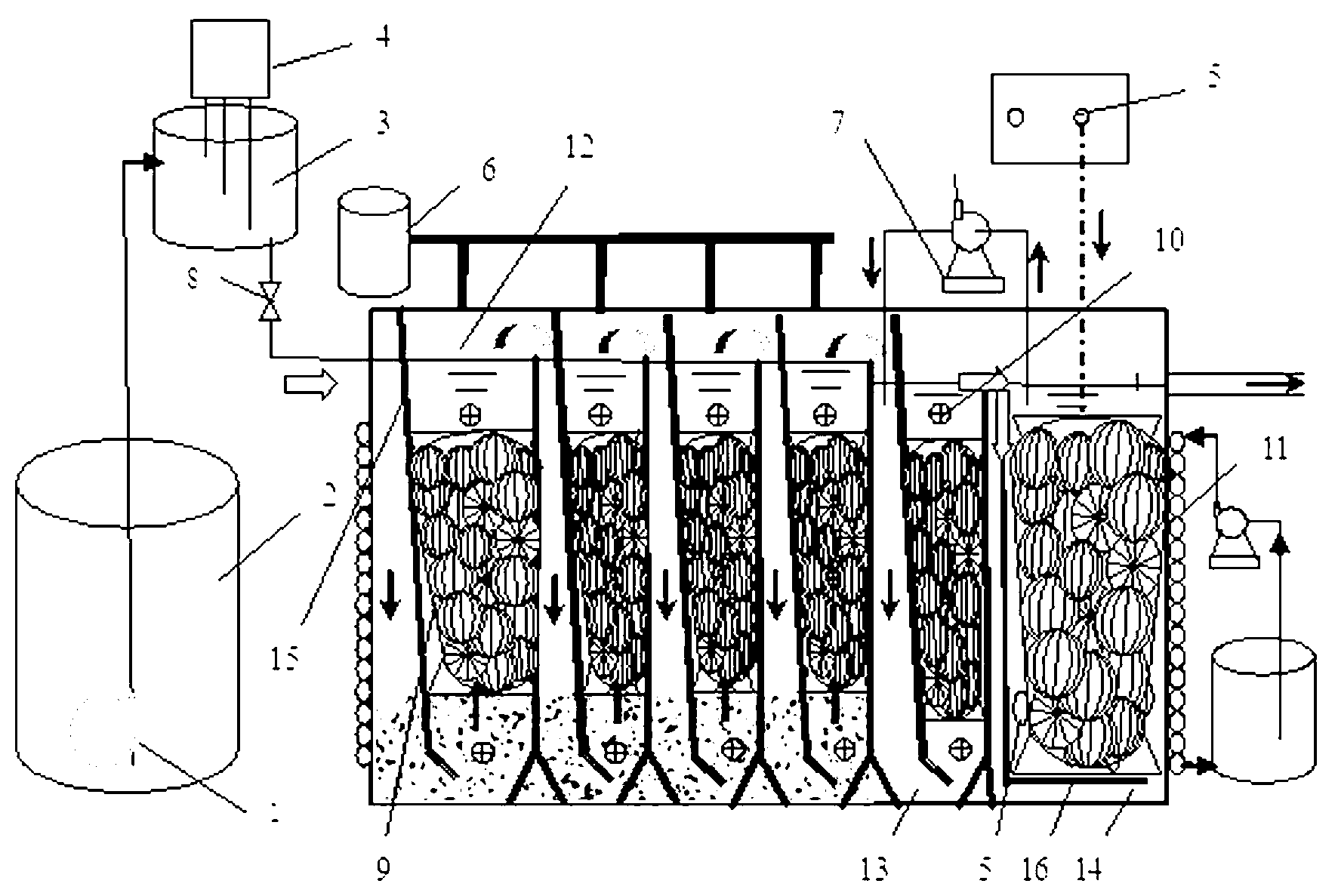

[0038] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0039] The cage packing type anaerobic-anoxic-aerobic treatment device for beer wastewater of this embodiment, such as figure 1 As shown, it includes water storage tank 2, elevated water tank 3, lift pump 1, ABR reaction tank 12, anoxic reaction tank 13, aerobic reaction tank 14, cage packing 9 and aeration device;

[0040] The water storage tank 2, the ABR reaction pool 12, the anoxic reaction pool 13 and the aerobic reaction pool 14 can all be built as underground structures, and the ABR reaction pool, the anoxic reaction pool and the aerobic reaction pool must be underground structures or above-ground structures at the same time. In order to maintain the reaction temperature and reduce the land occupation, especially in the northern region, it can reduce the adverse effects of freezing damage and low temperature on biochemical treatment; the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com