Production technology for glass reinforced plastic hand washer and face washing cabinet

A production process and hand sanitizer technology, applied in the direction of manufacturing tools, wood processing equipment, etc., can solve the problems of high production cost, long production cycle, complex manufacturing, etc., and achieve the effect of low production cost, short production cycle and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

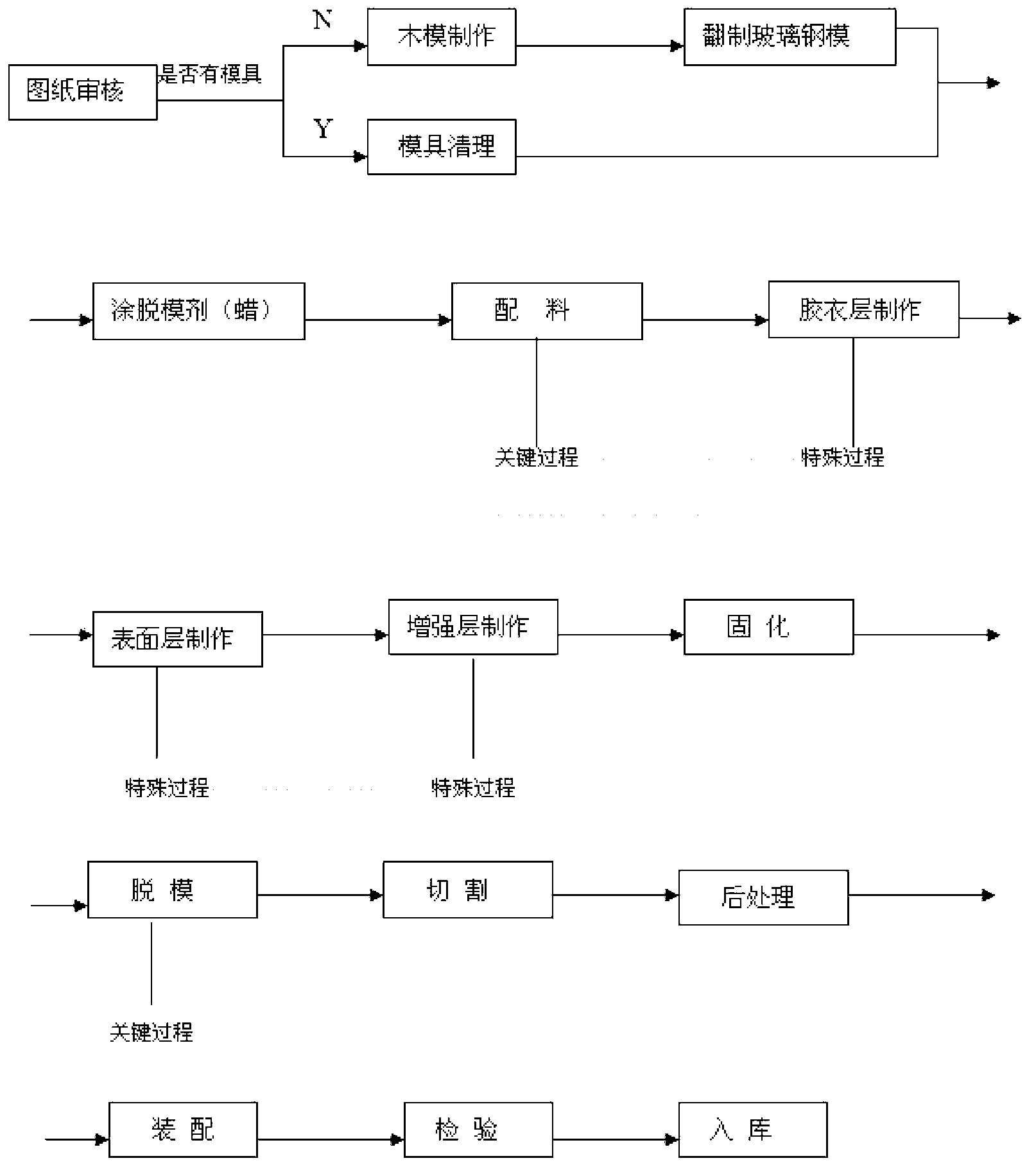

Method used

Image

Examples

Embodiment

[0050] (1) Wooden mold making for hand sanitizer

[0051]Choose 1260mm wood according to the size of the product drawing; divide the product into three parts according to the size of the product: the top of the hand washing device / washing counter, the facade and the inspection surface, and make wooden molds respectively. Mix the putty putty and methyl ethyl ketone curing agent evenly, the amount of curing agent is 1%, and then scrape it on the wooden mold with a greasy knife. The plane of the wooden mold should be smooth and smooth, and the arc transition should be smooth and round; Grind off the protruding part with coarse sandpaper, and then polish it with 150#-400# sandpaper in stages, if it is uneven, it needs to be repaired and then re-polished;

[0052] (2) FRP mold making

[0053] 2.1 Brushing the release agent: Clean the wooden mold, impregnate the PMR high-efficiency release agent with a clean soft cotton cloth, and apply it evenly on the mold in a circular manner, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com