Preparation method of silica core/mesoporous silica shell-supported gold nano-particle microspheres

A technology of mesoporous silica and gold nanoparticles, applied in the field of preparation of gold-loaded nanocatalysts, can solve the problems of poor morphology and uniformity of mesoporous silica-loaded gold catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

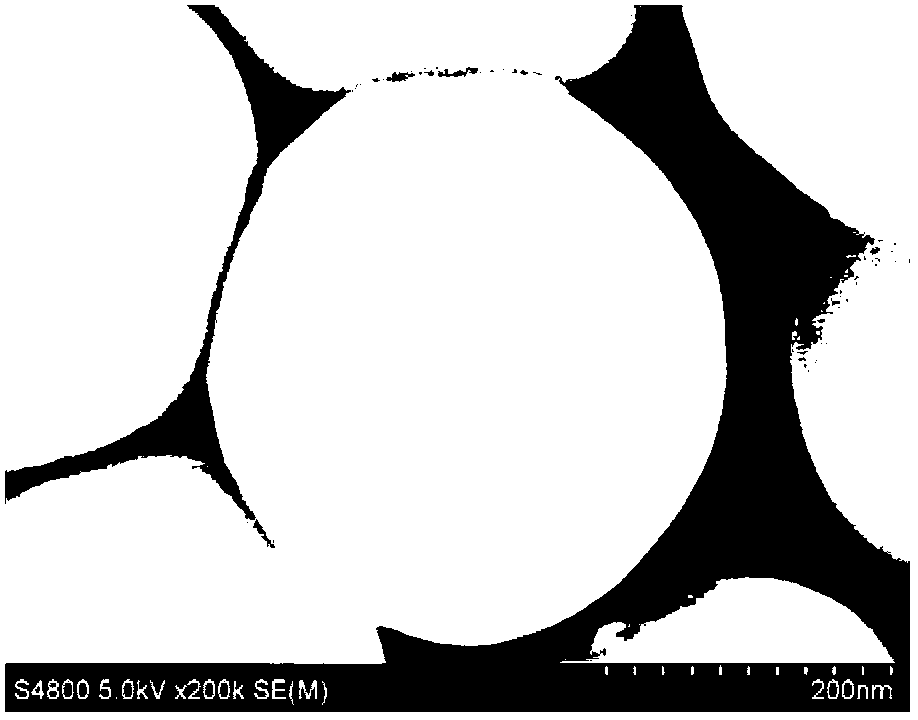

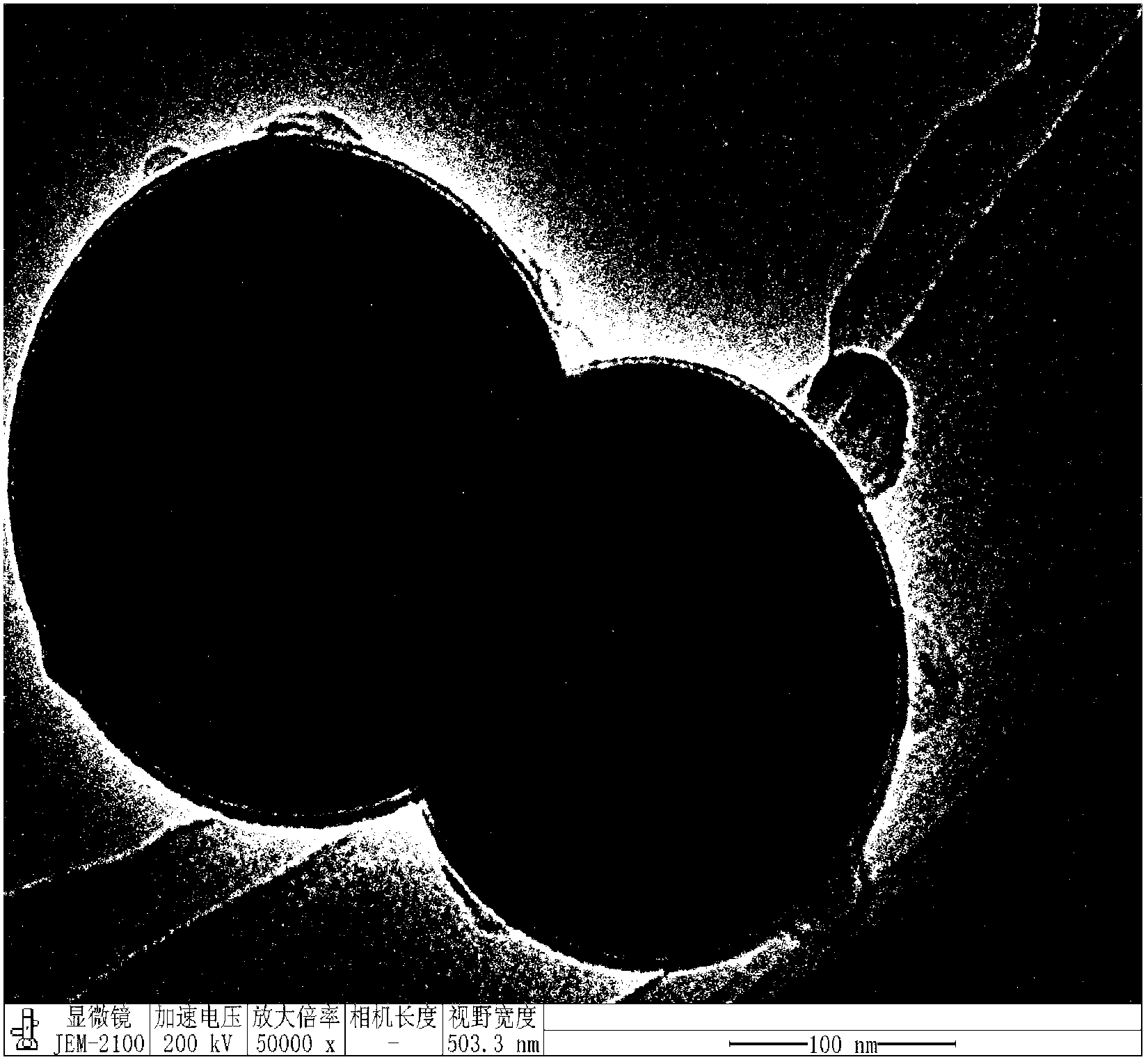

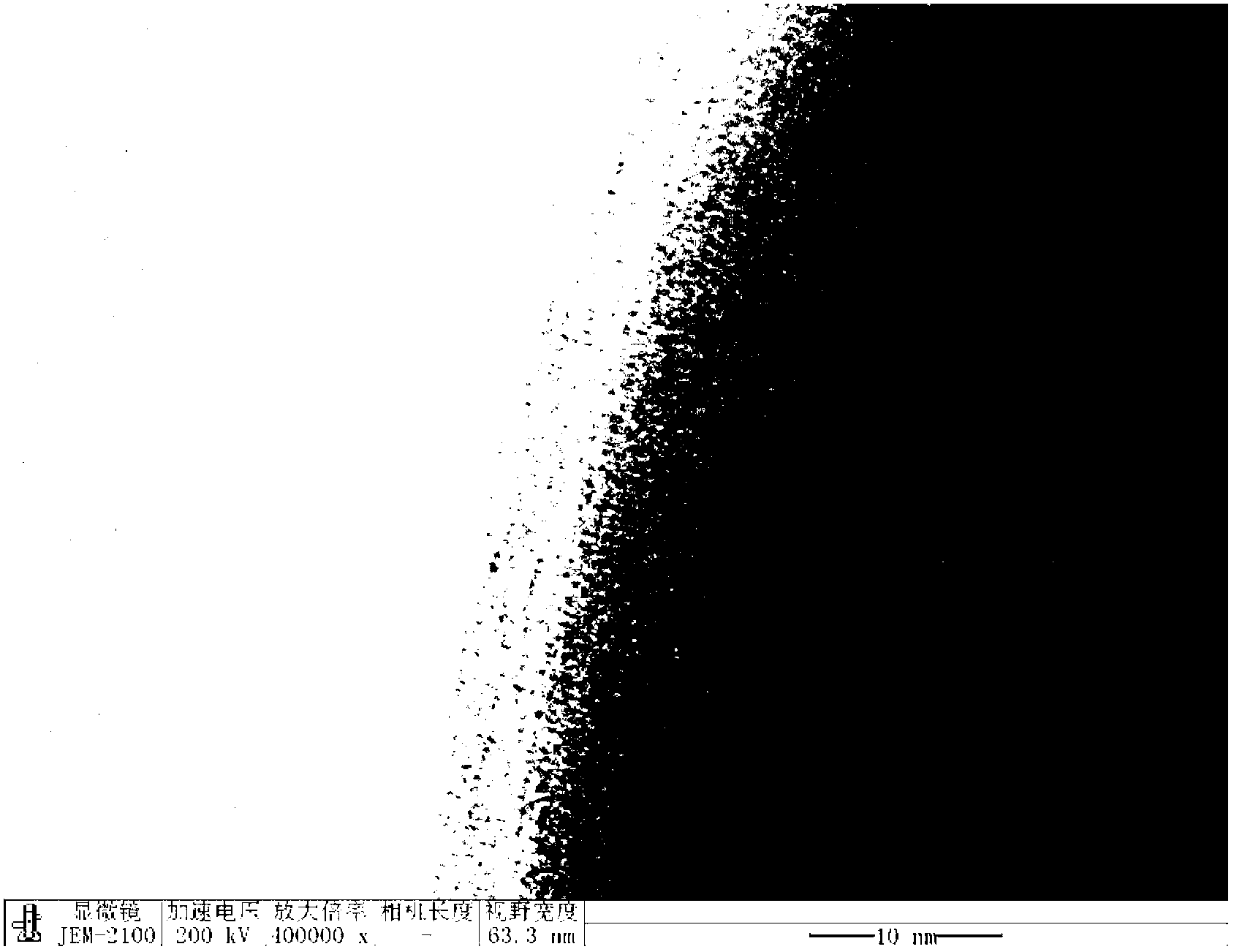

[0021] Embodiment 1: In this embodiment, the preparation method of silica core / mesoporous silica shell supporting gold nanoparticle microspheres is implemented according to the following steps:

[0022] 1. Preparation of silica nanoparticle sol solution: Mix 15-35mL of ammonia water with a mass concentration of 28%, 360-600mL of absolute ethanol and 30-60mL of deionized water, stir at room temperature for 20-40min, and then Add 25-50mL tetraethyl orthosilicate, and continue to stir for 5-8 hours to obtain a silica nanoparticle sol;

[0023] 2. Preparation of silica / mesoporous silica nanoparticles with core-shell structure: Dilute 100mL of silica nanoparticle sol with 165-230mL of deionized water, add 20-45mL of deionized water with a concentration of 110mmol / L Hexaalkyltrimethylammonium bromide solution, stirred for 20~40min, then added dropwise 1.6~3.1mL tetraethyl orthosilicate and continued to stir for 10~15h, the product was centrifuged and washed three times, then dried a...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment differs from Embodiment 1 in that step 2 adds 26-35 mL of cetyltrimethylammonium bromide solution with a concentration of 110 mmol / L. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0029] Embodiment 3: This embodiment differs from Embodiment 1 in that step 2 adds 30 mL of cetyltrimethylammonium bromide solution with a concentration of 110 mmol / L. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com