Rotary drum underflow pump flow-limiting plate

A technology of restricting plate and underflow pump, applied in the field of restricting plate of rotary drum underflow pump, can solve the problems of intolerance to erosion, waste of materials, time-consuming and labor-intensive, etc., and achieve the effect of prolonging service life and saving maintenance time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

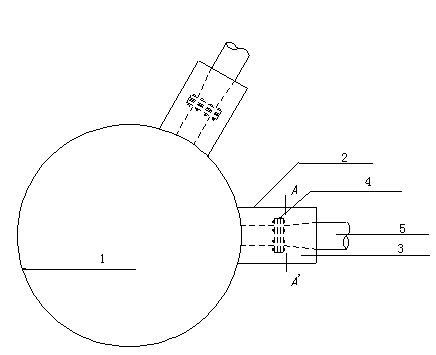

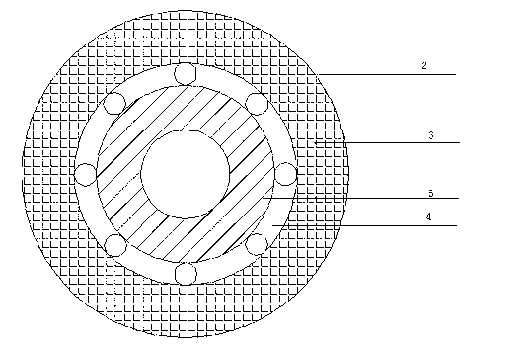

[0015] Replace the gasket at 4 of the flange restrictor plate to ensure that the quick-drying and quick-acting concrete will not be worn through before it solidifies. The upper and lower parts of the sealed chamber 2 with an inner diameter of 450 mm are respectively made of steel plates with a length of 600 mm and a thickness of 10 mm, and then the upper and lower parts are placed on the restrictor plate 4 to form a sealed chamber 2 covering the restrictor plate 4, and the One end of the sealed cavity 4 is welded on the blowing box 1, and the other end is closed and welded with a circular steel plate with a thickness of 10 mm and φ450*165 mm, and is centered on the delivery pipe 5. A pouring hole of φ100mm is opened in the middle of the sealed cavity 2, and concrete is poured into the pouring hole, and tamped with a vibrating rod to form a concrete layer 3, and its structure is as follows figure 1 with figure 2 shown. Since the conveying pipeline 5 is a difficult-to-weld st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com