Chip inductance element manufactured by low-temperature co-firing ferrite unsintered tape

A ferrite raw material, low-temperature co-firing technology, applied in the field of chip inductors and chip inductors, can solve the problem of high Curie temperature, achieve high Curie temperature, uniform distribution, and prevent device failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The method for making a chip inductance element from the low temperature co-fired ferrite raw tape of this embodiment includes:

[0041] Step 1: Preparation of low temperature co-fired ferrite raw tape:

[0042] 1.1. Weigh each component in the main material respectively, the main material includes: Fe 2 o 3 47-53mol%; NiO 18-25mol%; CuO 2-10mol%; ZnO 6-21mol%; 2 o 3 2-5mol%; the main material is wet-ground, dried, sieved and pre-fired, and the pre-fired ferrite powder is added with additives for secondary wet grinding to obtain pre-fired ferrite powder;

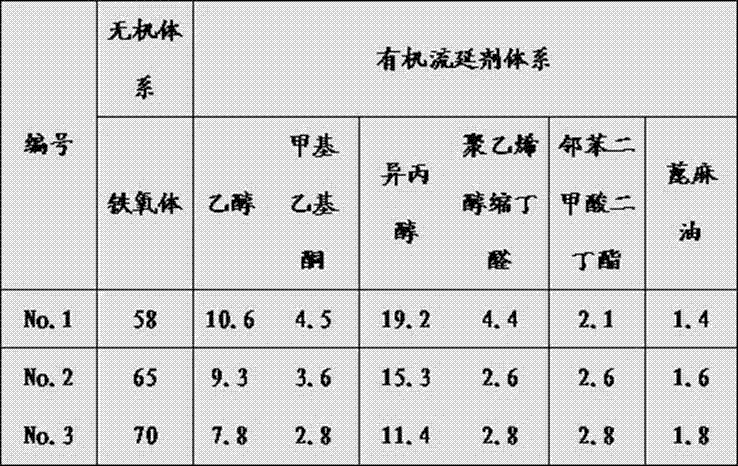

[0043] 1.2. Weigh the pre-fired ferrite powder prepared above, add solvent and dispersant and ball mill for 3-6 hours, add binder and plasticizer and ball mill for 3-6 hours, vacuum defoaming and then tape casting, After drying, a low-temperature co-fired ferrite raw tape is obtained;

[0044] Step 2: Preparation of chip inductor components:

[0045] 2.1. According to the structural design of the chip inducto...

Embodiment 2

[0064] Table 4 shows the content of each component of the specific example 2 of the present invention. Weigh the calcined ferrite powder according to the formula in Table 4, add solvent and dispersant and ball mill for 3-6 hours, add binder and plasticizer and ball mill for 3-6 hours, vacuum defoaming, tape casting, and drying to obtain The low-temperature co-fired ferrite raw tape of the present invention.

[0065] In the present invention, ring-cutting is performed on the prepared raw material tape, the temperature is raised to 450°C at 2°C / min and kept for 3 hours to remove glue, and then the temperature is raised from 450°C to 900°C for 3 hours at 2.5°C / min for sintering. During the cooling process, the temperature was controlled to drop to 250°C for 10 hours, and then cooled naturally with the furnace, and the performance of the sintered body was tested (see Table 5).

[0066]

[0067] Table 4 Contents of components in low temperature co-fired ferrite raw tape (wt%)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com