Method for preparing nitrogen-doped carbonaceous material by modifying polymer

A technology of carbonaceous materials and nitrogen-doped carbon, applied in the direction of carbon compounds, chemical instruments and methods, nano-carbon, etc., can solve the problems of low nitrogen doping, reduced electrical conductivity, and damage to the original structure of carbon materials, and achieves applicable Wide range of properties, simple process, and the effect of improving specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1, preparation of polymer modified nitrogen-doped carbon material polyaniline modified nitrogen-doped carbon nanotubes

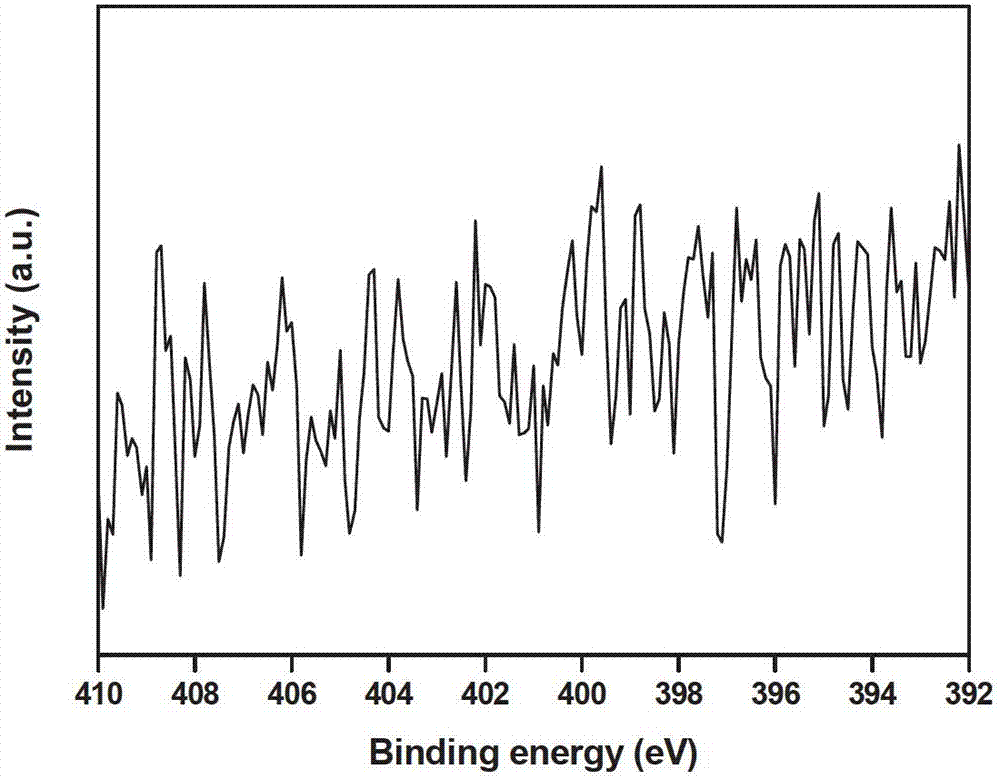

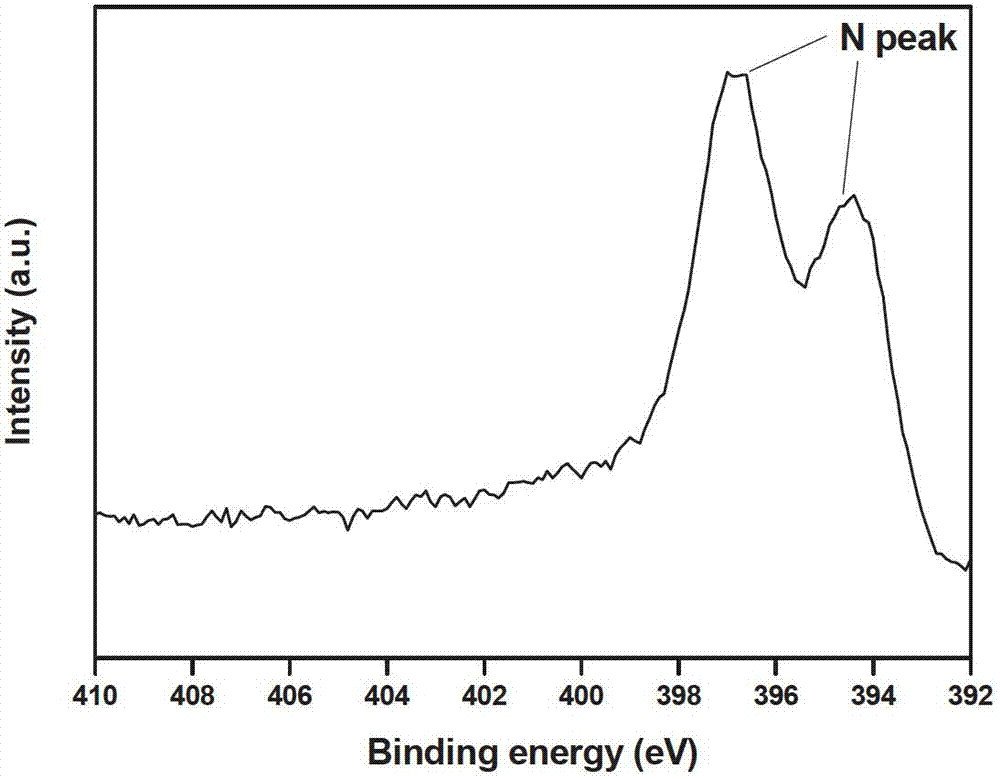

[0020] The multi-walled carbon nanotubes produced by a Japanese company are used, and the average outer diameter is 30-60nm. Weigh 60 mg, add it to a hydrochloric acid solution with a concentration of 0.2 mol / L, then add 0.35 g of aniline, and ultrasonically disperse for 0.5 hours. Stir at room temperature for 0.5 hours, add 0.5 g of ammonium persulfate, continue to stir for 1.5 hours, then cool the solution to 0~5°C in an ice-water mixed bath, then wash with deionized water, filter, and filter the obtained product in the Vacuum drying at 80°C for 10 hours; the dried product was heat-treated at 600°C under the protection of nitrogen, the heating rate was 5°C / min, the constant temperature time was 1 hour, and then naturally cooled to room temperature. The X-ray photoelectron spectrum of the multi-walled carbon nanotube before and after the abo...

Embodiment 2

[0021] Example 2, preparation of polymer modified nitrogen-doped carbon material polypyrrole modified nitrogen-doped activated carbon

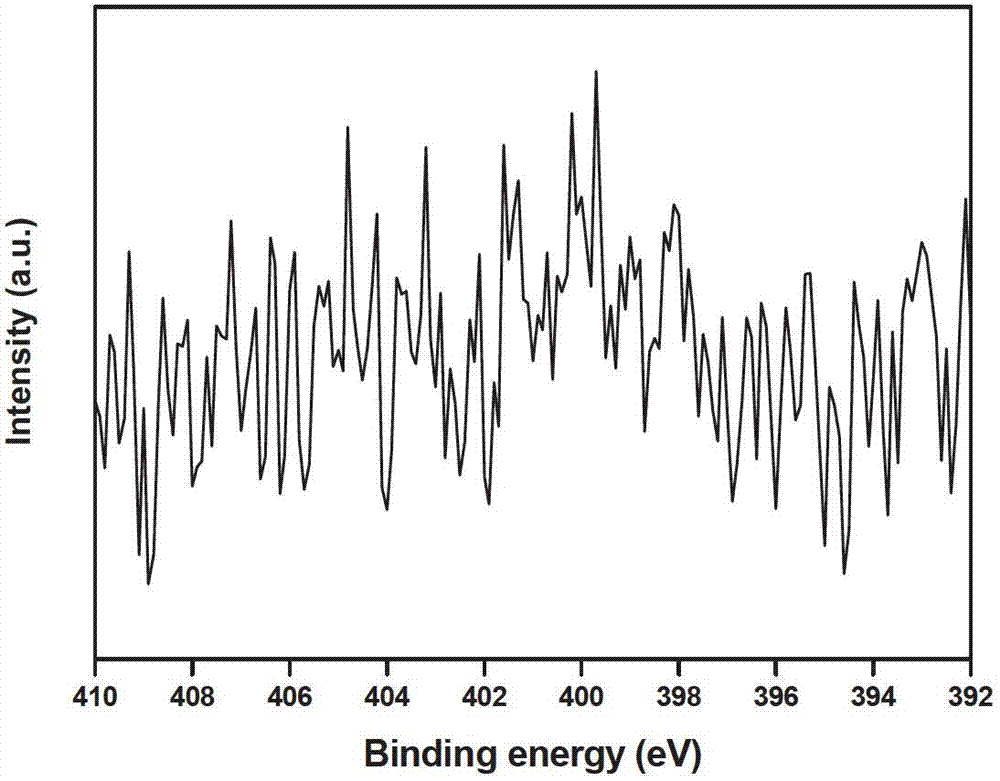

[0022] The activated carbon prepared by CVD method has an average diameter of 60nm. No nitrogen element before nitrogen doping. Weigh 1 g of activated carbon, add it to a hydrochloric acid solution containing 0.5 g of pyrrole and a concentration of 1 mol / L, then add 1 g of ammonium persulfate, and continue stirring for 1.5 hours at room temperature. Repeated washing with deionized water and membrane filtration. Dry under vacuum at 40°C for 16 hours. Heat treatment at 850°C under the protection of nitrogen, with a heating rate of 4°C / min, constant temperature for 2 hours, and natural cooling. As determined by X-ray photoelectron spectroscopy, see image 3 , Figure 4 , it can be seen that the nitrogen-doped activated carbon of the product prepared by the method of this embodiment contains 13% atomic percentage of nitrogen. The prepared ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com