Turnover device of pulley of heavy steel structural part

A technology of steel structural parts and pulleys, which is applied in the field of turning over devices for large steel structural parts, can solve problems such as waste of production time, breakage, and wire rope breakage, and achieve the effects of increasing service life, reducing damage, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

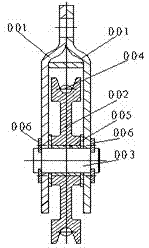

[0010] Such as figure 1 A pulley turning device for a large steel structure is shown, including a coupling plate 001, a grooved pulley 002, a shaft 003, and an annular steel wire 004. The coupling plate 001 is two elongated plates corresponding to each other. The upper ends are respectively bent inwards and fastened to form a coupling shell. The two coupling plates 001 are provided with a through hole near the bottom. Between the plates 001, both ends of the shaft 003 are respectively fixedly connected with the through holes on the coupling plate 001, and the annular steel wire rope 004 penetrates into the coupling housing formed by the two coupling plates 001, and is placed on the grooved pulley 002. There is a copper sleeve 005 between the grooved pulley 002 and the shaft 003, and a coupling plate 006 is provided at both ends of the shaft 003. The coupling plate 006 is two pieces that are engaged with each other, and the end of the shaft 003 is engaged with the coupling plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com