Composite material with foam sandwich structure and preparation method of composite material

A composite material and sandwich technology, applied in the field of composite materials, can solve the problems of high-cost precision and mechanical control, and achieve the effects of enhancing bending strength and compressive strength, strengthening connection, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

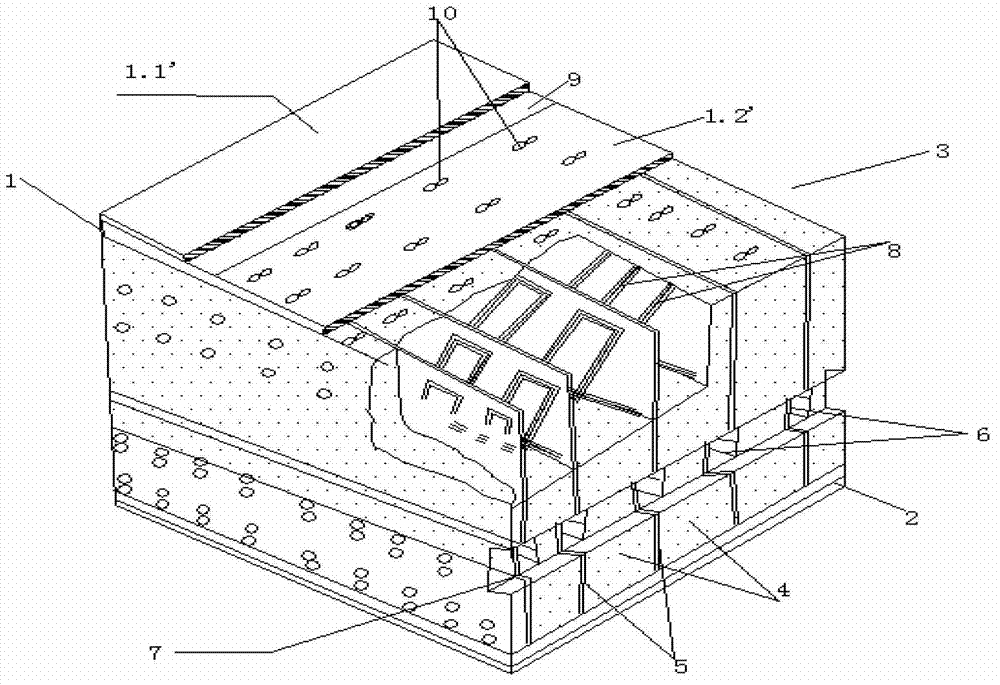

[0035] The structure of the foam sandwich structure composite material of this embodiment is as follows figure 1 As shown, the upper surface layer 1 and the lower surface layer 2 are laminated by eight layers of glass fiber fabrics, and the upper four layers and the lower four layers of the upper surface layer 1 and the lower surface layer 2 are separated by epoxy resin adhesive interlayers. 9 Separated to form an outer surface layer 1.1' and an inner surface layer 1.2', the foam sandwich layer 3 is arranged in parallel with a plurality of foam strips 4 (the left and right directions are arranged in parallel in the figure), and sheet glass fiber fabric is sandwiched between the foam strips 5. The angle between the sheet glass fiber fabric 5 and the upper surface layer 1 and the lower surface layer 2 is a right angle; on the middle surface of every two foam strips 4, there are rectangular cross-section resin grooves 6 parallel to the surface layer (in the figure is the front-to...

Embodiment 2

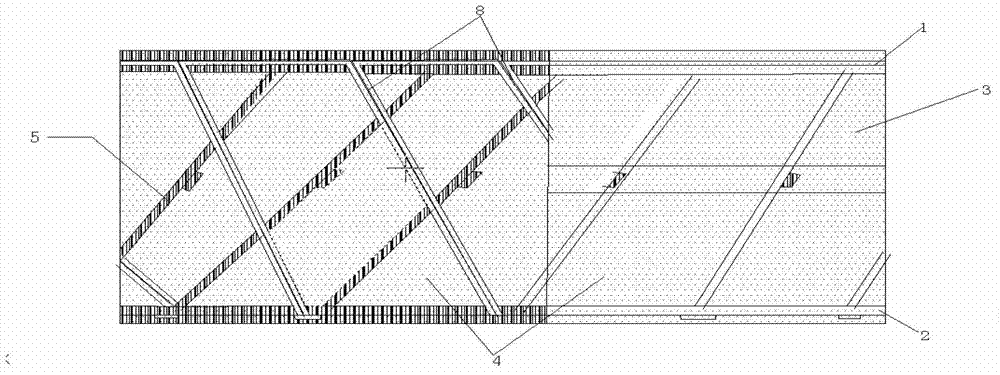

[0042] Such as figure 2 Shown, the structure of this embodiment composite material is the same as figure 1 Similarly, the angle between the sheet glass fiber fabric 5 and the upper surface layer 1 and the lower surface layer 2 is 45 degrees, and the cross section of the foam strip 4 is a parallelogram, which is stitched at a single angle of 45 degrees (the suture line formed by sewing the roving 8 45-degree angle with the upper and lower surfaces at intervals, without crossing), so that the production efficiency can be greatly improved.

Embodiment 3

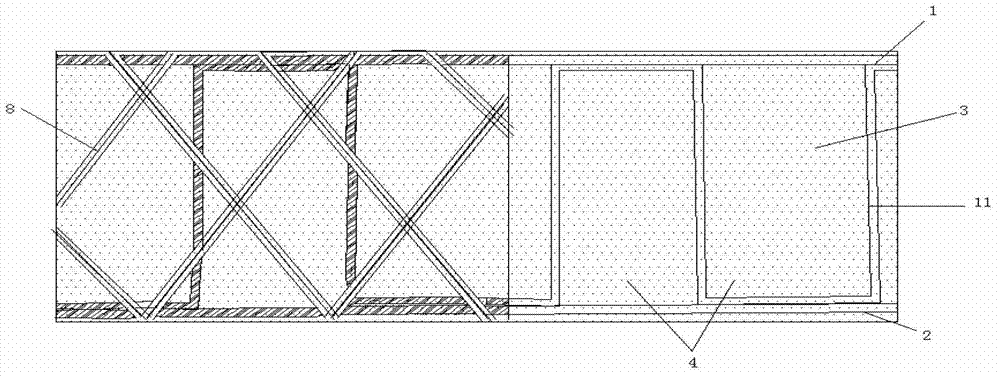

[0044] Such as image 3 Shown, the structure of this embodiment composite material is the same as figure 1 Basically the same, except that the glass fiber fabric used for reinforcement in the foam sandwich layer 3 is continuous, extending between the two surface layers in a continuous shape, which greatly improves the fiber fabric 11 and the surface layer 1, The 2 contact area also gives more support to the stitched roving 8 in the transverse direction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com