Enteromorpha prolifera dried meat floss and preparation method thereof

A technology of meat floss and enteromorpha, applied in the field of enteromorpha meat floss and its preparation, can solve the problems of failure to form food and ineffective use of enteromorpha, and achieve the effects of helping digestion and absorption, shortening drying time, and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

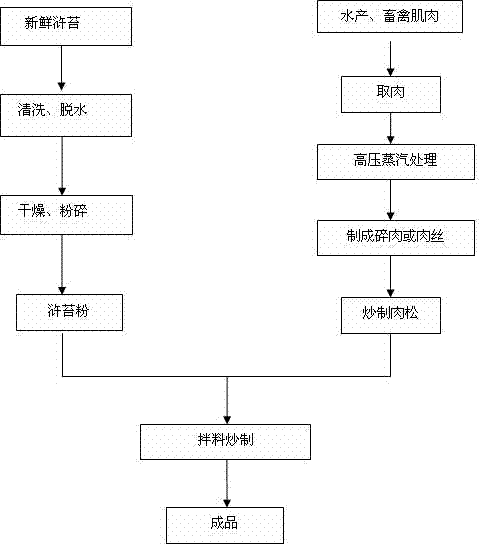

Method used

Image

Examples

preparation example Construction

[0030] 1. Preparation of Enteromorpha powder

[0031] Salvaged fresh Enteromorpha, cleaned and dehydrated by a centrifugal dehydrator at a speed of 5000 rpm, dehydrated for 10 minutes, then dried in an oven at a drying temperature of 100°C±5°C, drying time of 4-5 hours, moisture content Control it at 10%-15%, crush it to 40 mesh with a pulverizer, and set it aside.

[0032] 2. Preparation of meat floss:

[0033] a. After washing sea fish, removing heads, fins and viscera, treat them with high-pressure steam for 3 to 5 minutes, then remove bone spurs and peritoneum while still hot, and smash the fish meat for later use.

[0034] b. Stir fried pine: Put 3000 grams of minced fish into the fried meat floss machine, add seasonings: 50 grams of cooking wine, 120 grams of sugar, 150 grams of salt, 50 grams of monosodium glutamate, 80 grams of soy sauce, and fry for about 30 minutes until the color of the meat turns yellow , fluffy and fluffy.

[0035] 3. Stir fry

[0036] Add 200...

Embodiment 2

[0039] 1. Preparation of Enteromorpha powder

[0040] Salvaged fresh Enteromorpha, cleaned and dehydrated by a centrifugal dehydrator, the centrifugal dehydrator rotates at 8,000 rpm, and after centrifugal dehydration for 7 minutes, it is dried in an oven at a drying temperature of 95±5°C and a drying time of 5-6 hours. The content is controlled at 10%-15%, and then pulverized to 80 mesh with a pulverizer for later use.

[0041] 2. Preparation of meat floss

[0042] a. Remove the fat and fascia from the pork, pre-cook it, change the water after boiling, add green onions, ginger and aniseed ingredients, etc., and treat it with high-pressure steam for 10-15 minutes. After cooling, use a special wire drawing machine to draw the meat into shreds shape.

[0043] b. Fried pine: Put 4000 grams of shredded pork into the fried meat floss machine, add seasonings: 60 grams of cooking wine, 200 grams of sugar, 180 grams of salt, 80 grams of monosodium glutamate, 100 grams of soy sauce, ...

Embodiment 3

[0047] 1. Preparation of Enteromorpha powder

[0048] Enteromorpha is freshly salvaged. After cleaning, it is dehydrated by a centrifugal dehydrator. The centrifugal dehydrator rotates at 8000 rpm. After centrifugal dehydration for 7 minutes, it is dried in an oven. The drying temperature is 95±5℃, the drying time is 5-6 hours, and the moisture content is controlled at 10%-15%. Then pulverize to 80 mesh with a pulverizer and set aside.

[0049] 2. Preparation of meat floss

[0050] a. Remove the fat and fascia from the pork, pre-cook it, change the water after boiling, add green onions, ginger and aniseed ingredients, etc., and treat it with high-pressure steam for 10-15 minutes. After cooling, use a special wire drawing machine to draw the meat into shreds shape.

[0051] b. Fried pine: Put 5000 grams of shredded pork into the fried meat floss machine, add seasonings: 90 grams of cooking wine, 250 grams of sugar, 210 grams of salt, 100 grams of monosodium glutamate, 130 gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com