Method and device for cooling high-temperature waste gas and recovering waste heat

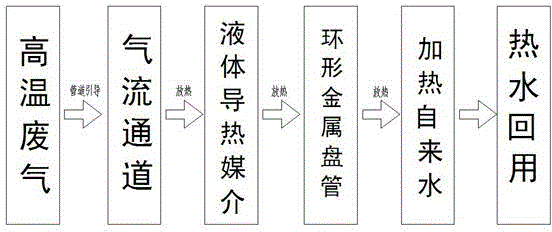

A high-temperature waste gas and waste heat recovery technology, applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of low cooling efficiency, large equipment volume, secondary pollution of sewage, etc., to achieve good cooling effect, The effect of high heat exchange efficiency and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

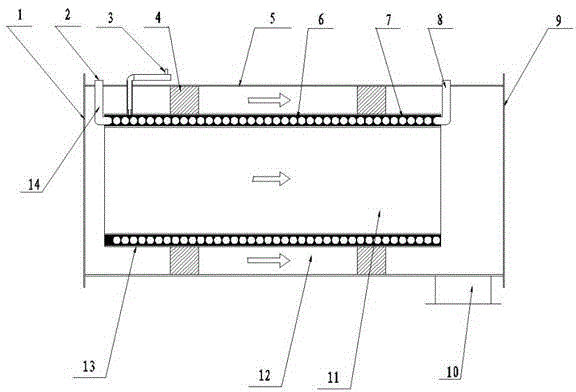

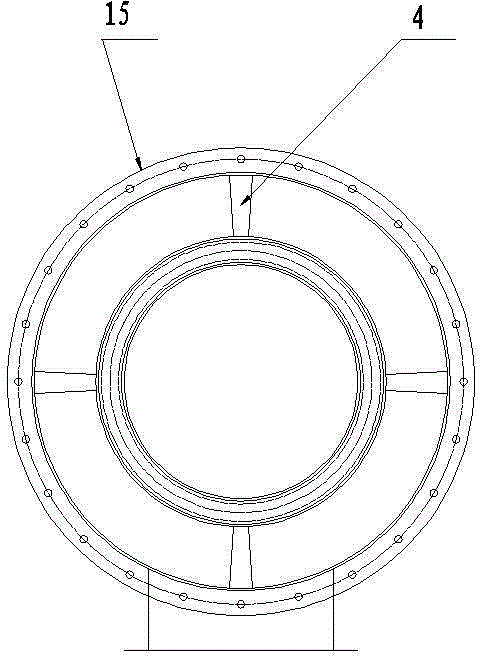

[0047] A high-temperature exhaust gas cooling and waste heat recovery device: the shell 5 of the device is a hollow cylinder with openings at both ends, with a built-in heat exchange unit cylinder 13, and the two are connected by fixed ribs 4; the heat exchange unit cylinder 13 is also a hollow cylinder shape, its outer wall and inner wall enclose a closed liquid storage chamber 6, the liquid storage chamber 6 is provided with a metal tube 7 coiled and the inner wall of the heat exchange unit cylinder 13; the two ends of the shell 5 are air inlet 1 or air outlet 9 ; The heat exchange unit cylinder 13 divides the cylindrical space surrounded by the shell 5 into two layers inside and outside; the two ends of the metal pipe 7 pass through the two ends of the heat exchange unit cylinder 13 and the shell 5 respectively, and are the water inlet 2 and the water outlet 8 ; In addition, there is a pipeline passing through the shell 5 and communicating with the liquid storage chamber 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com