Prevention and treatment method for full-mechanized caving mining collapse trap area water disaster for shallow-buried ultra-thick coal seam

A technology for thick coal seams and subsidence pits is applied in the field of water hazard prevention and control in fully mechanized caving mining of shallow buried and huge thick coal seams, which can solve problems such as lack of control methods, and achieve the effects of controlling water potential hazards, good safety and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

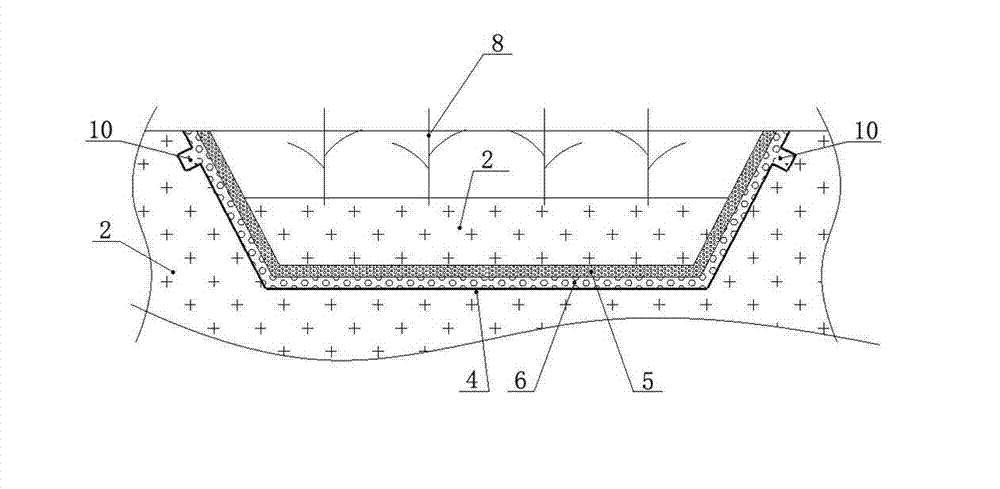

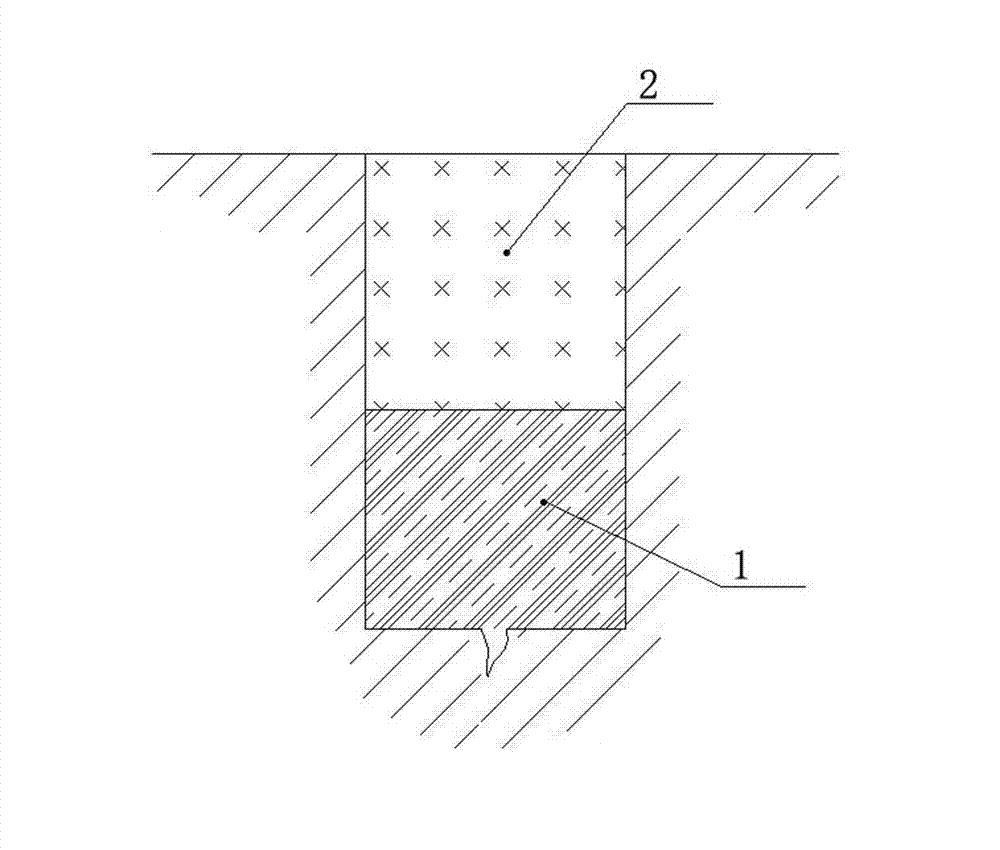

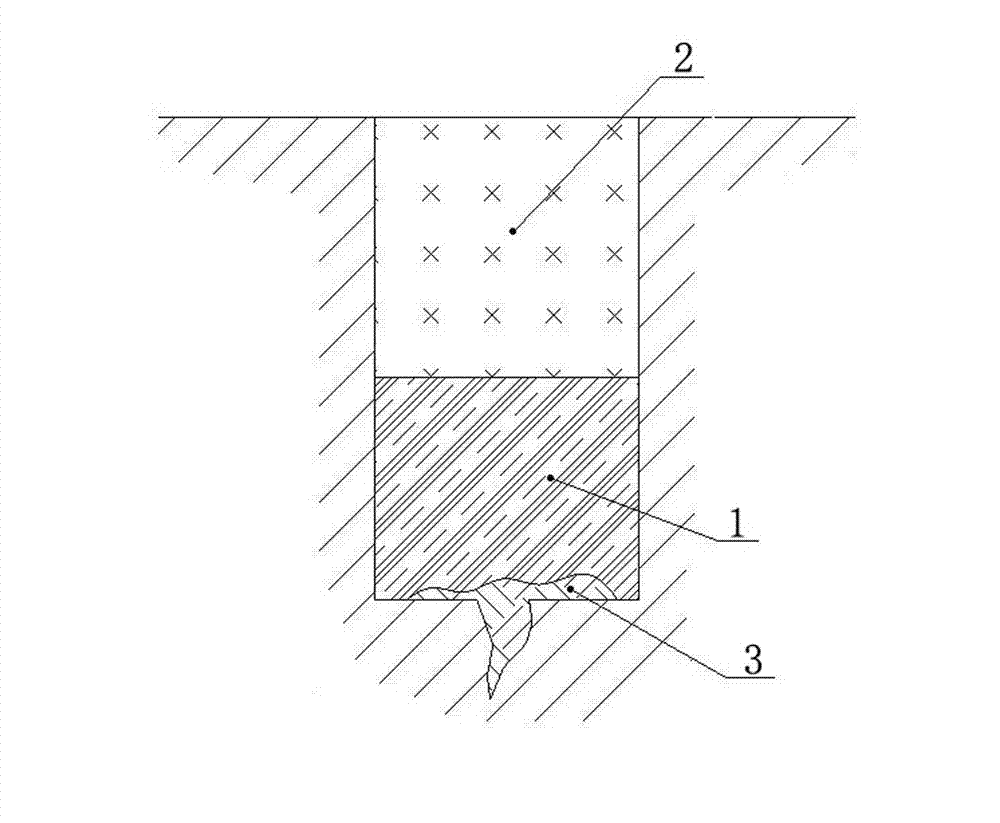

[0029] Such as Figure 1 to Figure 5As shown, a method for preventing and controlling water hazards in the subsidence pit area of fully mechanized caving mining in shallow buried huge thick coal seams includes the following steps:

[0030] 1) The shallow, moderate and deep fissures in the subsidence pit area are rammed and filled respectively. The method of ramming and filling the shallow and moderate fissures is as follows: firstly, the upper parts of the shallow and moderate fissures are excavated into deep 1.5m, 0.5m wide trench, and then fill it manually with notoginseng ash 1, and tamp once every time a maximum of 0.2m thick notoginseng ash 1 is added until the thickness of the rammed notoginseng ash 1 reaches 0.5m , The compactness is not less than 93%. After the Panax notoginseng ash soil 1 is filled and compacted, then the loess 2 backfill is carried out. The bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com