Piston dust shield material for automobile braking system and preparation method thereof

A technology of automobile braking system and dust cover, applied in mechanical equipment, engine components, engine sealing and other directions, can solve problems such as restricting the development of automobile manufacturers, shorten the filling time, speed up the flow speed, and prevent material shortage. and flow marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

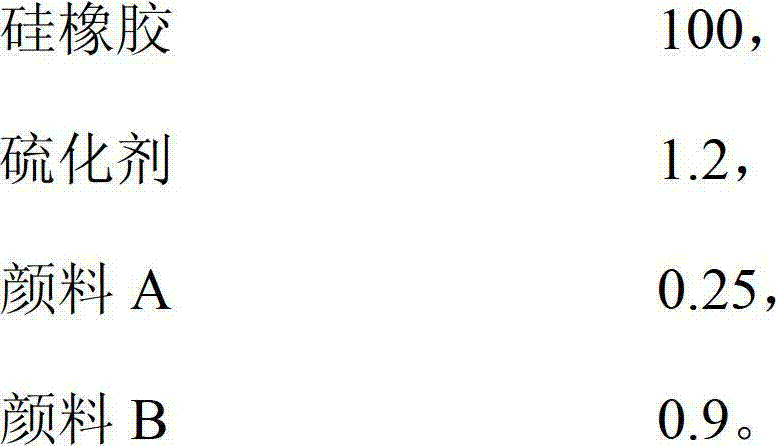

[0086] A piston dust cover material for an automobile brake system, which is composed of the following raw material components in proportion by weight: silicone rubber R750 (Germany Wacker) 100, vulcanizing agent bis-251.2, iron oxide black 4330 (Germany Bayferrox) ) 0.25, #2108 silicone color paste (Kunshan Fangyuan Silicon Material Co., Ltd.) 0.9.

[0087] The method for preparing the piston dust cover from the above-mentioned materials comprises the following steps:

[0088] (1) Immerse the skeleton of the piston dust cover completely in the adhesive for 3 minutes. The adhesive is a mixture of the adhesive Chemlok 608 and absolute ethanol at a mass ratio of 1:1. After taking it out, dry it at 95°C for 12 minutes. spare;

[0089] (2) Mix each raw material component according to the formula quantity, and press the molded part;

[0090] (3) Put the skeleton of the piston dust cover in step (1) into the mold, and preheat for 60 seconds at a temperature of 170°C;

[0091] (4)...

Embodiment 2

[0098] A piston dust cover material for an automobile brake system, which is composed of the following raw material components in proportion by weight: silicone rubber R420 (Wacker, Germany) 120, vulcanizing agent PDM 0.8, iron oxide red 4120 (Bayferrox, Germany) 0.3, Bayferrox silicone color paste (Bayferrox Germany) 0.7.

[0099] The method for preparing the piston dust cover from the above-mentioned materials comprises the following steps:

[0100] (1) Immerse the skeleton of the piston dust cover completely in the adhesive Chemlok 238 for 4 minutes, take it out and dry it at 100°C for 10 minutes, and set it aside;

[0101] (2) Mix each raw material component according to the formula quantity, and press the molded part;

[0102] (3) Put the skeleton of the piston dust cover in step (1) into the mold, and preheat it at 175°C for 50 seconds;

[0103] (4) Put the formed part of step (2) into the mold, at a temperature of 175°C and 50kgf / cm 2 Carry out a vulcanization for 42...

Embodiment 3

[0110] A piston dustproof cover material for an automobile brake system, which is composed of the following raw material components in proportion by weight: silicone rubber R401 / 90 (Wacker, Germany) 80, vulcanizing agent DCP1.5, 1630 light chrome yellow (Jiangsu Shuangle Chemical Pigment Co., Ltd.) 0.2, #2222 silica gel color paste (Kunshan Fangyuan Silicon Material Co., Ltd.) 1.2.

[0111] The method for preparing the piston dust cover from the above-mentioned materials comprises the following steps:

[0112] (1) Completely immerse the skeleton of the piston dust cover in the adhesive for 2 minutes. The adhesive is BD802 rubber-metal adhesive produced by Xiangfan Lianji Adhesive Factory. After taking it out, dry it at 90°C for 15 minutes and set it aside;

[0113] (2) Mix each raw material component according to the formula quantity, and press the molded part;

[0114] (3) Put the skeleton of the piston dust cover in step (1) into the mold, and preheat it for 70s at a temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com