Blending type rubber compound and preparation method thereof

A technology of mixing rubber and blending type, which is applied in the field of mixing rubber and its preparation, can solve the problems of high cost and poor oil resistance, and achieves improved performance indicators, improved performance indicators, and increased vulcanization speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of blended rubber compound, the content ratio of each raw material component is as follows in parts by weight:

[0041] EPDM (ethylene propylene diene monomer) 80 parts,

[0042] Rubber type CPE (chlorinated polyethylene material) 20 parts,

[0043] DCP (plasticizer, di-sec-octyl phthalate) 2.5 parts,

[0044] TAIC (cross-linking agent, triallyl isocyanurate) 1 part,

[0045] 30 parts of talcum powder,

[0046] N660 (carbon black) 30 parts,

[0047] TP759 (polyester plasticizer) 5 parts,

[0048] SA (accelerator) 1 part,

[0049] ZnO (zinc oxide) 5 parts.

[0050] And it is prepared by the following steps:

[0051] The first step is to adjust the roller distance of the double-roller mill to 0.5mm, shape the EPDM (ethylene propylene diene monomer), and make a triangular bag five times; add rubber-type CPE (chlorinated polyethylene material), a total of After mixing, thin pass five times; adjust the roller distance to 1mm, add ZnO (zinc oxide), TP759 (polye...

Embodiment 2

[0057] A kind of blend type rubber compound, its preparation method is the same as embodiment 1, difference is, its each raw material component content proportioning is by weight:

[0058] 75 parts of EPDM (ethylene propylene diene monomer),

[0059] Rubber type CPE (chlorinated polyethylene material) 25 parts,

[0060] DCP (plasticizer, di-sec-octyl phthalate) 3.5 parts,

[0061] TAIC (crosslinking agent, triallyl isocyanurate) 1.2 parts,

[0062] 30 parts of talcum powder,

[0063] N660 (carbon black) 30 parts,

[0064] TP759 (polyester plasticizer) 6 parts,

[0065] SA (accelerator) 1 part,

[0066] ZnO (zinc oxide) 5 parts.

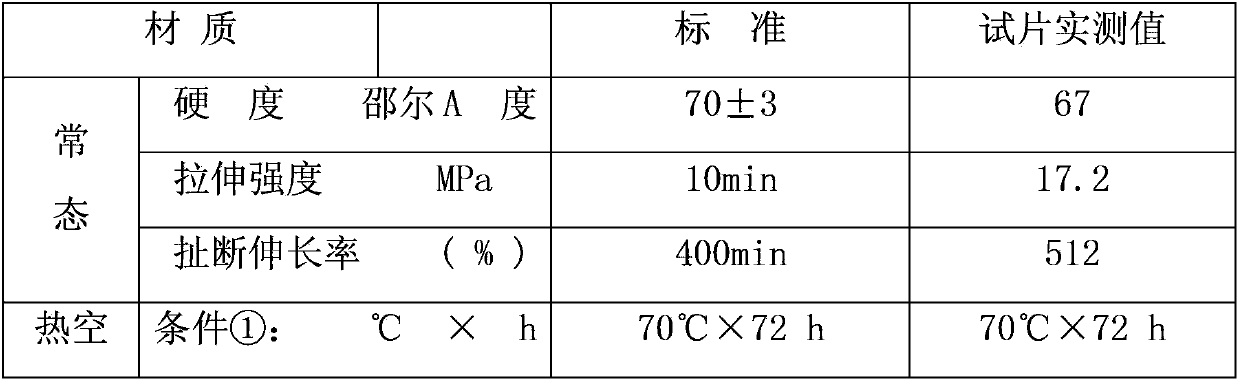

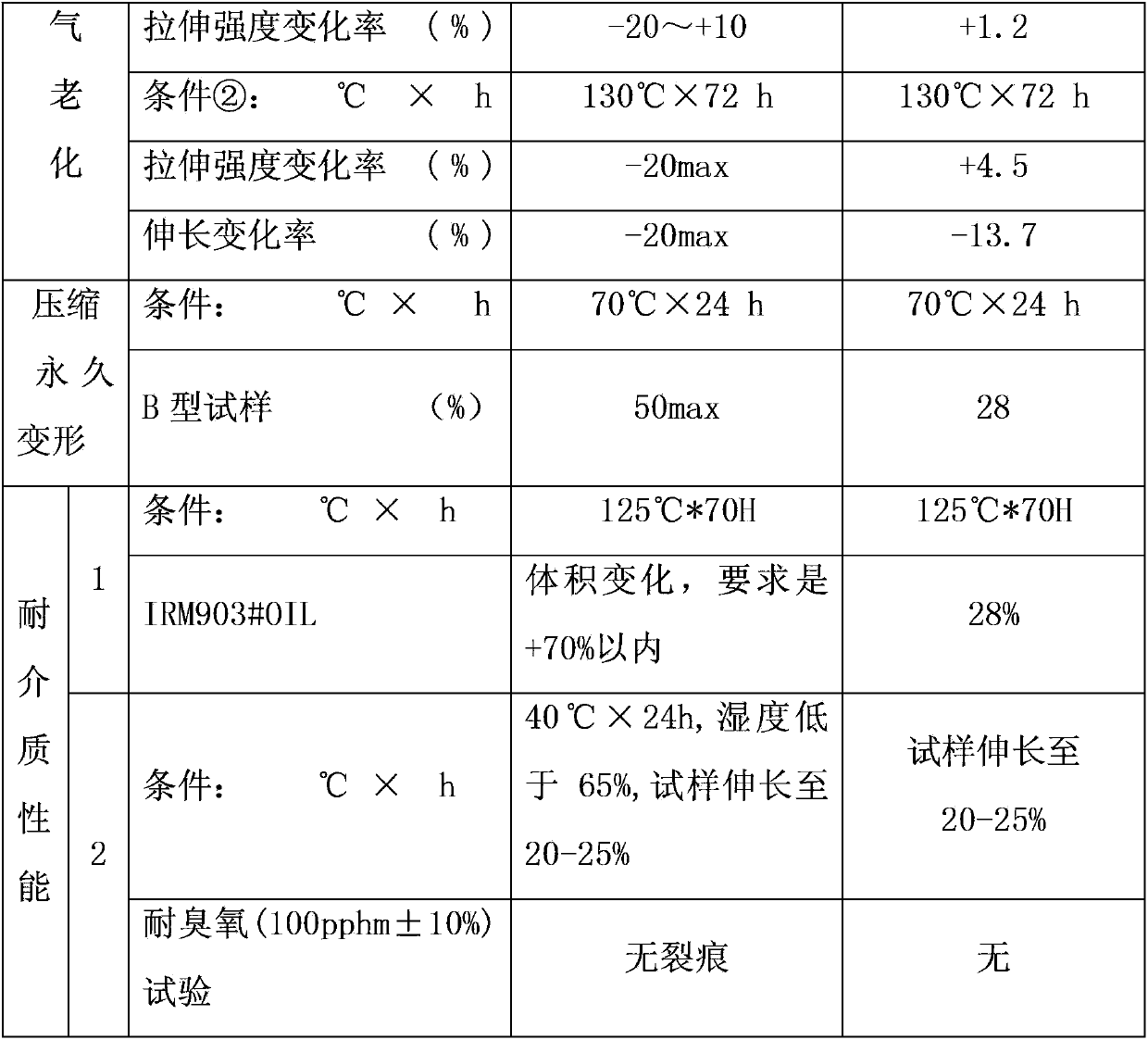

[0067] Its related properties are as follows:

[0068]

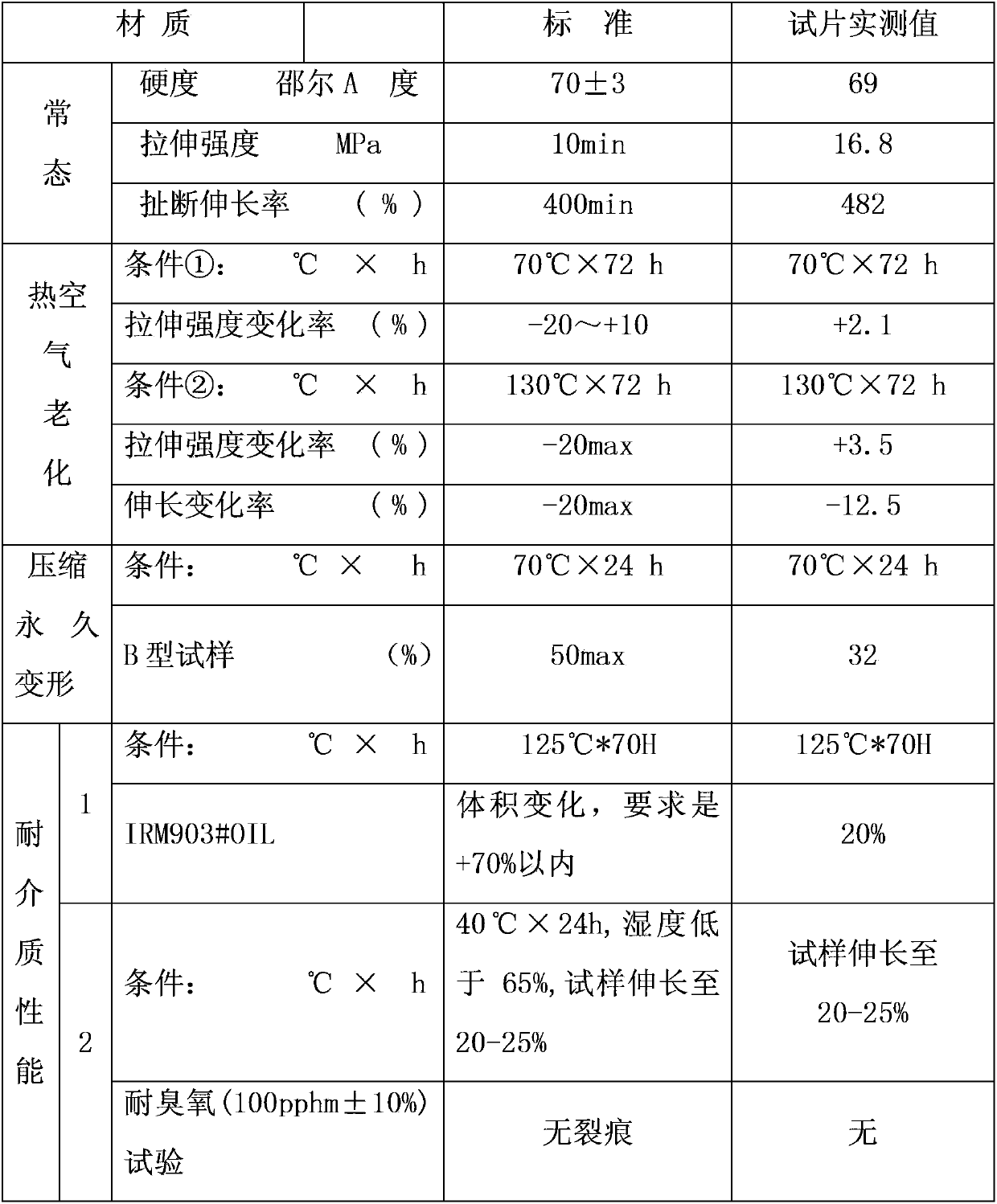

Embodiment 3

[0070] A kind of blend type rubber compound, its preparation method is the same as embodiment 1, difference is, its each raw material component content proportioning is by weight:

[0071] 75 parts of EPDM (ethylene propylene diene monomer),

[0072] Rubber type CPE (chlorinated polyethylene material) 15 parts,

[0073] DCP (plasticizer, di-sec-octyl phthalate) 2 parts,

[0074] 0.8 parts of TAIC (cross-linking agent, triallyl isocyanurate),

[0075] 25 parts of talcum powder,

[0076] N660 (carbon black) 25 parts,

[0077] TP759 (polyester plasticizer) 4 parts,

[0078] SA (accelerator) 1 part,

[0079] 3 parts of ZnO (zinc oxide);

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com