Catalyst used for preparing trichlorosilane through silicon tetrachloride cold hydrogenation, and preparation method thereof

A technology of silicon tetrachloride and trichlorosilane, which is applied in the directions of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, halide silicon compound, etc., can solve the problem of high production cost, trichlorosilane High cost, high energy consumption and other problems, to achieve the effect of excellent high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

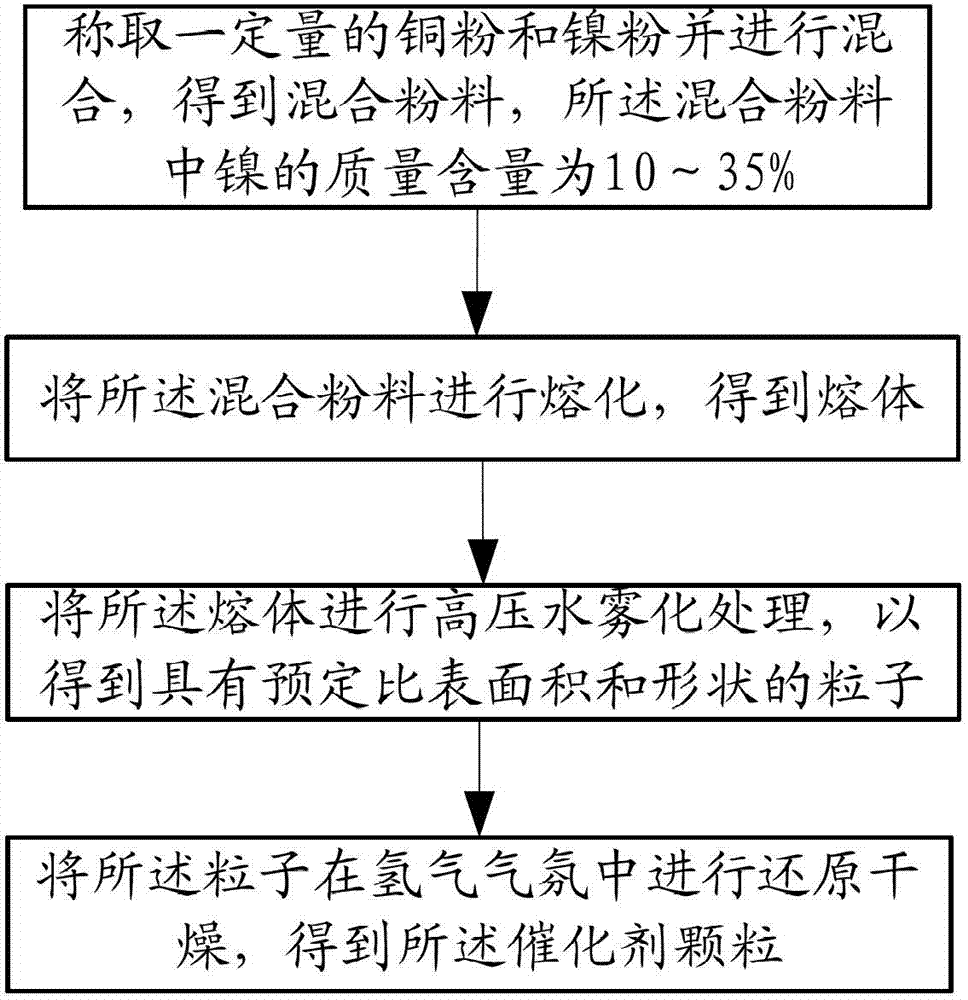

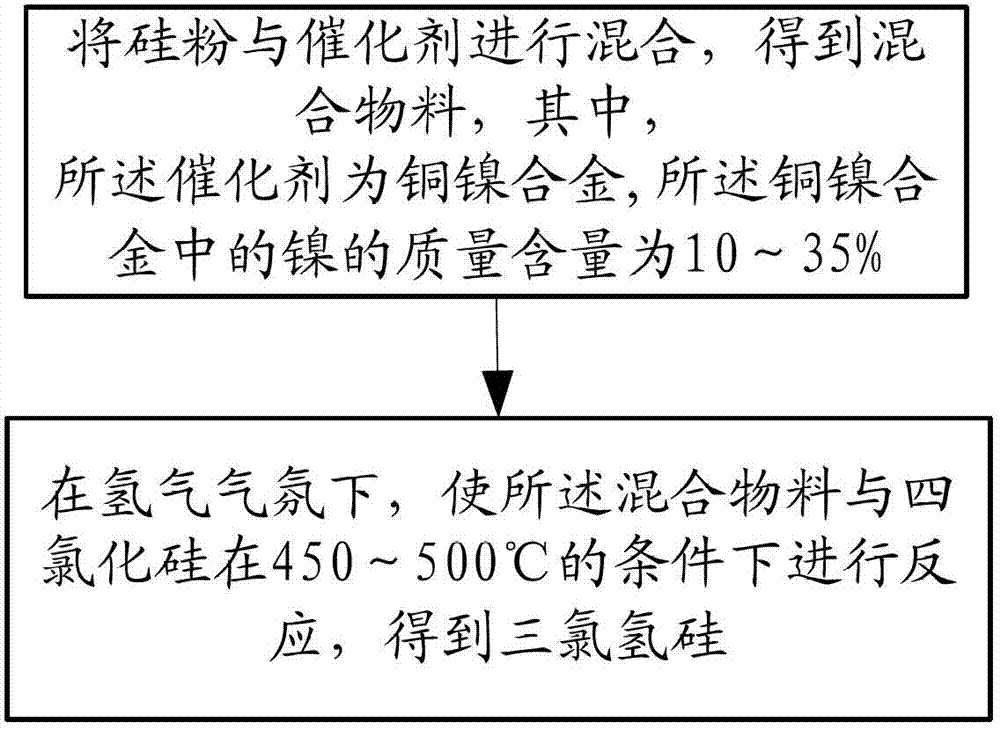

[0034] Concretely, the preparation method of the catalyst for preparing trichlorosilane by cold hydrogenation of silicon tetrachloride involved in the present invention comprises the following steps:

[0035] a) weighing and mixing a certain amount of copper powder and nickel powder to obtain a mixed powder, the mass content of nickel in the mixed powder is 10% to 35%;

[0036] b) melting the mixed powder to obtain a melt;

[0037] c) subjecting the melt to high-pressure water atomization treatment to obtain particles with a predetermined specific surface area and shape;

[0038] d) reducing and drying the particles in a hydrogen atmosphere to obtain the catalyst particles.

[0039] Thus, a catalyst for preparing trichlorosilane by cold hydrogenation of silicon tetrachloride can be prepared, the mass content of nickel in the mixed powder is 10-35%, and the prepared catalyst has excellent high-temperature stability, and can be used at high temperature There is no sticking phe...

Embodiment 1

[0058] Weigh 90g of copper powder and 10g of nickel powder and mix to obtain a mixed powder, which is melted to obtain a melt; the melt is subjected to high-pressure water atomization treatment at a pressure of 2MPa to obtain a specific surface area of 30m 2 / g of roughly spherical particles; the particles were reduced and dried in a hydrogen atmosphere to obtain catalyst particles.

[0059] The catalyst particles were pulverized and sieved to obtain a catalyst powder with a particle size of 10-200 mesh and a bulk density of 2.6 g / ml.

Embodiment 2

[0061] Weigh 65g of copper powder and 35g of nickel powder and mix to obtain a mixed powder, melt the mixed powder to obtain a melt; process the melt with high-pressure water atomization at a pressure of 5MPa to obtain a specific surface area of 80m 2 / g of roughly spherical particles; the particles were reduced and dried in a hydrogen atmosphere to obtain catalyst particles.

[0062] The catalyst particles were crushed and sieved to obtain a catalyst powder with a particle size of 10-200 mesh and a bulk density of 2.9 g / ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com