Phase-changing memory unit with similar super lattice structure and preparation method thereof

A phase change storage and superlattice technology, applied in the field of microelectronics, can solve the problems of slow phase change, poor thermal stability and data retention, and large operating current, so as to improve stability and facilitate precise control of super Lattice structure and subsequent process, the effect of reducing "write" current and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

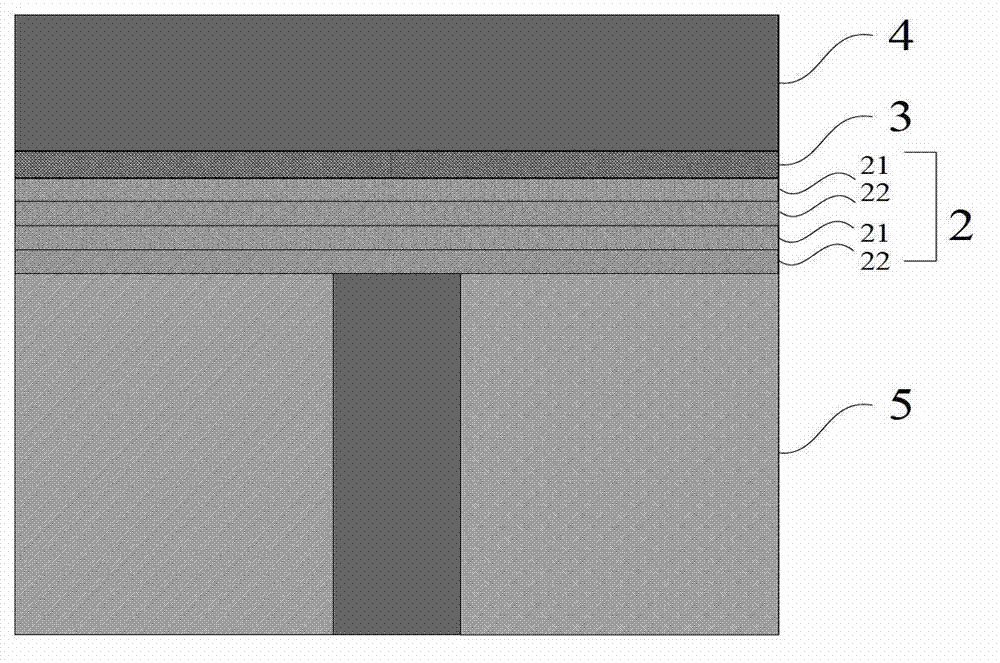

[0048] see figure 1 Shown, a kind of phase-change memory unit, it comprises lower electrode 1, the dielectric layer 5 that wraps lower electrode 1, the phase-change material layer 2 that is positioned at dielectric layer 5, is positioned at this phase-change material layer 2 heating layer 3 and is positioned at The electrode 4 on the heating layer 3. The phase change material layer is composed of a single layer of GaSb and a single layer of phase change material Sb 2 Te 3 A superlattice-like structure formed by alternating periodic growth of monolayers with nanometer thickness. The phase-change material layer 2 (that is, the superlattice-like structure includes a single-layer GaSb layer 21, a single-layer phase-change material Sb layer on the single-layer GaSb layer 21 2 Te 3 Layer 22, located in the single layer phase change material Sb 2 Te 3 The single-layer GaSb layer 21 on the layer 22...and so on, the structure can be repeated periodically until the thickness of the...

Embodiment 2

[0061] In this embodiment, Step 1 and Step 3 are the same as Embodiment 1. Also includes the following steps:

[0062] Step 4: Set the RF power corresponding to the GaSb alloy target to 25 watts, the Ar flow rate to 20 SCCM, and wait until the background vacuum is lower than 3×10 -4 Pascal, turn on the RF power supply, open the Ar inlet valve, open the GaSb alloy target cover and count the time, after 80 seconds of sputtering, turn off the GaSb alloy target RF power supply and the target cover, the thickness of the single-layer GaSb sputtered this time is 4nm.

[0063] Step 5: Add Sb 2 Te 3 The radio frequency power corresponding to the alloy target is set to 20 watts, the Ar flow rate is set to 20 SCCM, and the background vacuum is lower than 3×10 -4 Pascal, turn on the RF power, open the Ar inlet valve, open the Sb 2 Te 3 The alloy target is covered and timed. After 60 seconds of sputtering, the GaSb alloy target RF power supply and the target cover are turned off. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com