Air preheater and application thereof

An air preheater and cold air technology, which is applied in the field of flue gas waste heat recovery, can solve the problem of not solving the problem of unsolved flue gas condensation and releasing latent heat to preheat air, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

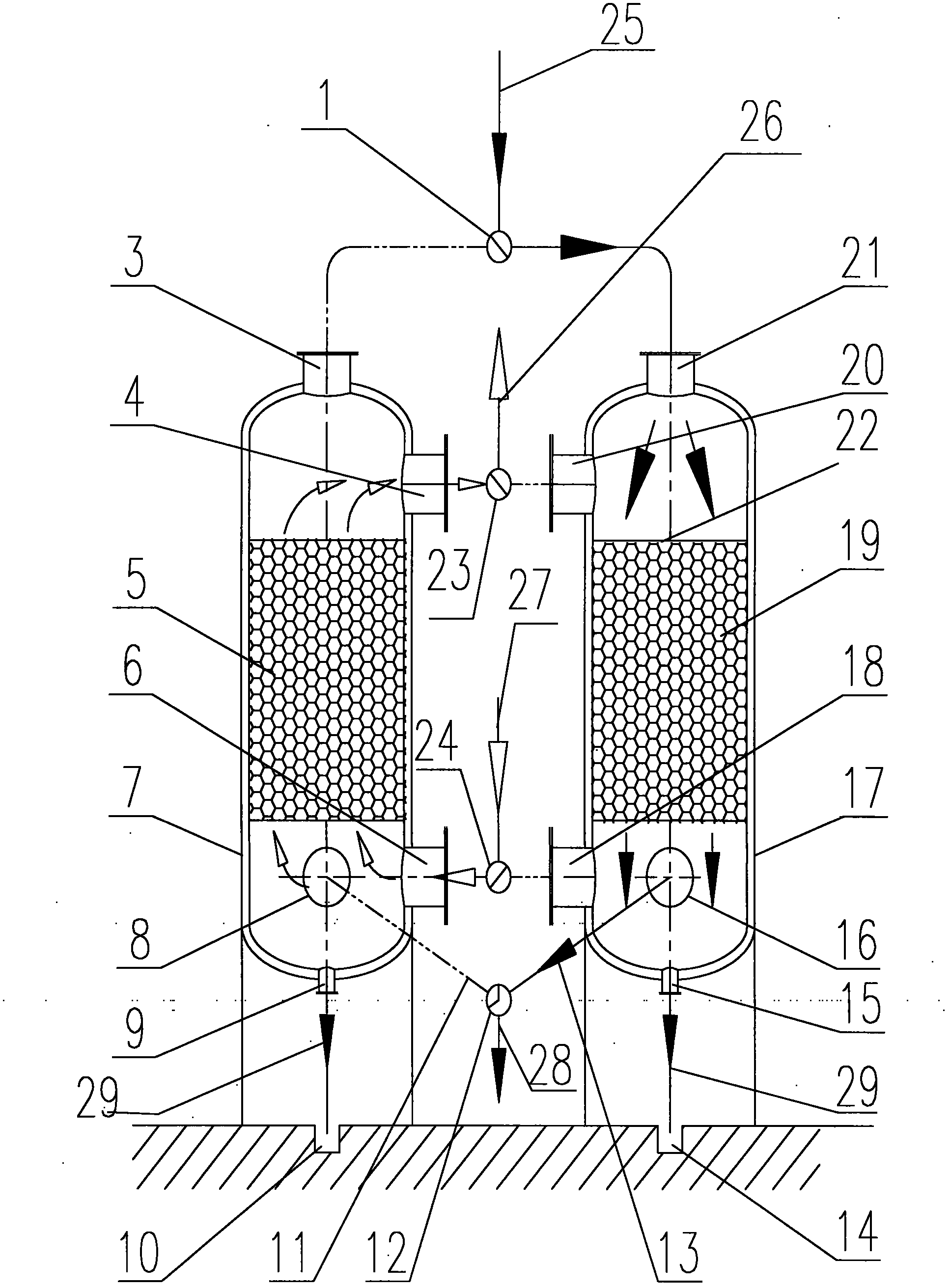

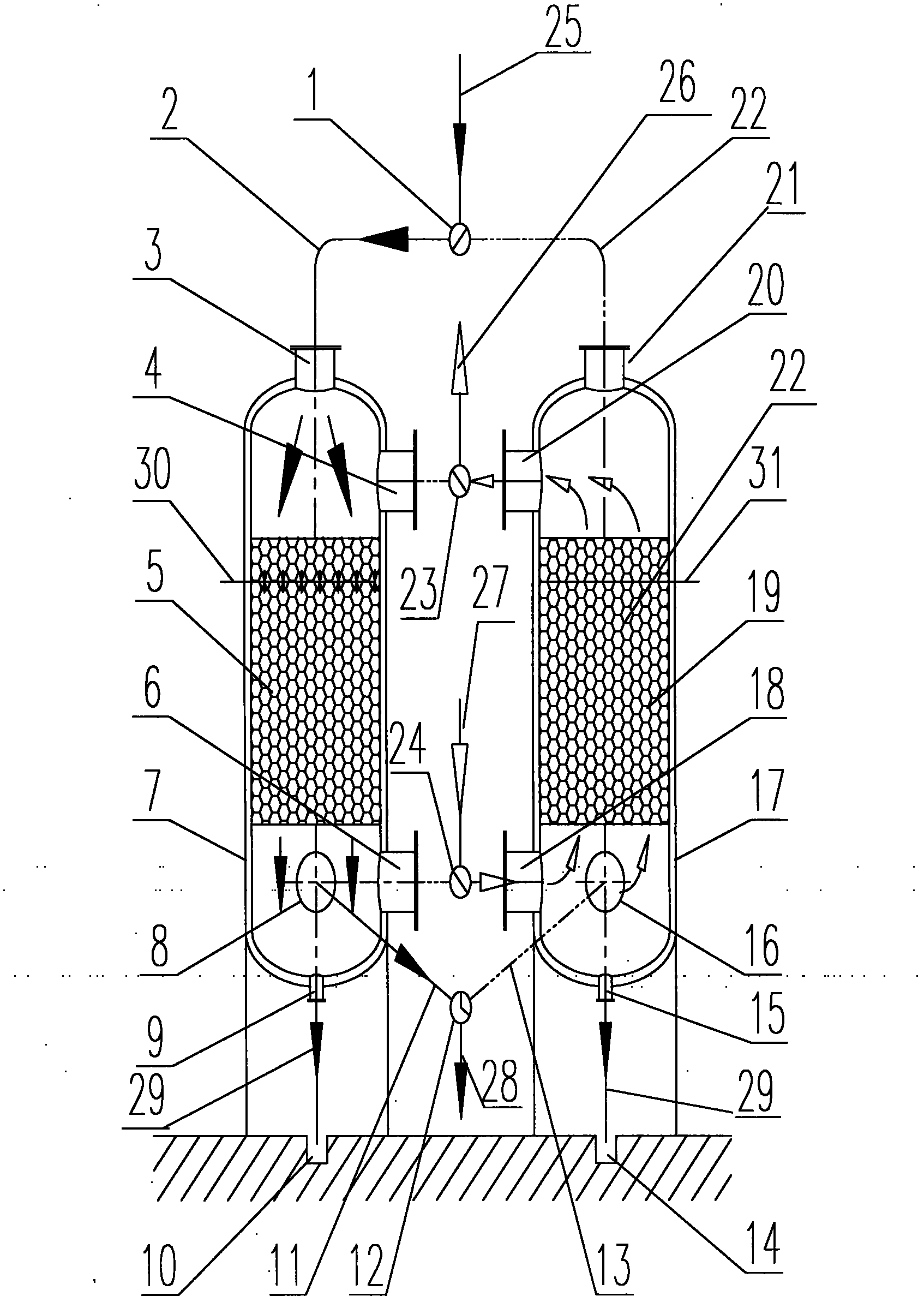

[0031] figure 1 It is a schematic diagram of state 1 of an air preheater of the present invention, heat storage chamber A stores heat, heat storage chamber B releases heat, and heat storage chamber 2 is composed of a shell 7, a three-way valve for hot flue gas 1, and flue gas from heat storage chamber A. Inlet 3, Regenerator A air outlet 4, Regenerator A heat storage medium 5 is a ceramic ball with a diameter of 15mm, Regenerator A air inlet 6, Regenerator A cold flue gas outlet 8, Regenerator A condensate outlet 9. Regenerator A condensate collection tank 10, regenerator A outlet flue 11 and cold flue gas three-way valve 12, regenerator A flue gas inlet 3 is set at the top of regenerator A, regenerator A The air outlet 4 is set at the upper part of the regenerator A, the air inlet 6 of the regenerator A is set at the lower part of the regenerator A, the cold flue gas outlet 8 of the regenerator A is set at the lower part of the regenerator A, and the condensate outlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com