Outer wall vacuum inorganic foam insulation plate and manufacturing method thereof

A technology of inorganic foam and thermal insulation board, which is applied in the field of thermal insulation of building walls, can solve problems such as low temperature resistance, failure to meet energy-saving standards, complicated manufacturing process, etc., and achieve good waterproof performance, outstanding thermal insulation performance, and good safety and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

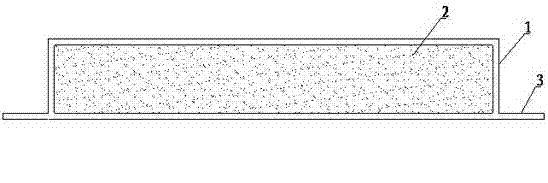

[0019] Embodiment 1: as figure 1 As shown, a vacuum inorganic foam insulation board for external walls, the insulation board is made of a vacuum packaging bag 1 and a foam insulation core board 2 contained in the bag, and the foam insulation core board 2 is a foam cement board or a foam glass board or a foam One of the ceramic plates, the vacuum packaging bag 1 is an aluminum foil vacuum packaging bag, with construction and installation edges 3 pressed on both sides or around the aluminum foil vacuum packaging bag, and a layer of outer wall is brushed on the outward surface of the aluminum foil vacuum packaging bag Thermal insulation and waterproof coating.

[0020] A horizontal or vertical groove is pressed on the surface of the foam insulation core board 2, and the horizontal or vertical groove forms a circle of grooves around the thin plate, and a circle of grooves is filled with the inner surface of the vacuum packaging bag. of adhesives.

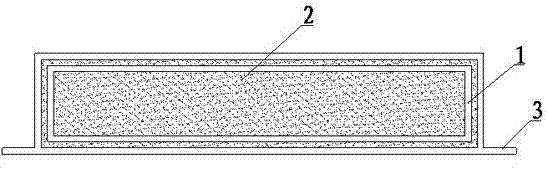

[0021] Such as figure 2 As s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com