Method for selective leaching separation of cobalt, nickel and molybdenum from high grade cobalt-nickel-molybdenum waste material

A high-grade, selective technology, applied in the direction of improving process efficiency, can solve problems that have not been reported, and achieve obvious effects, reduce adverse effects, and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

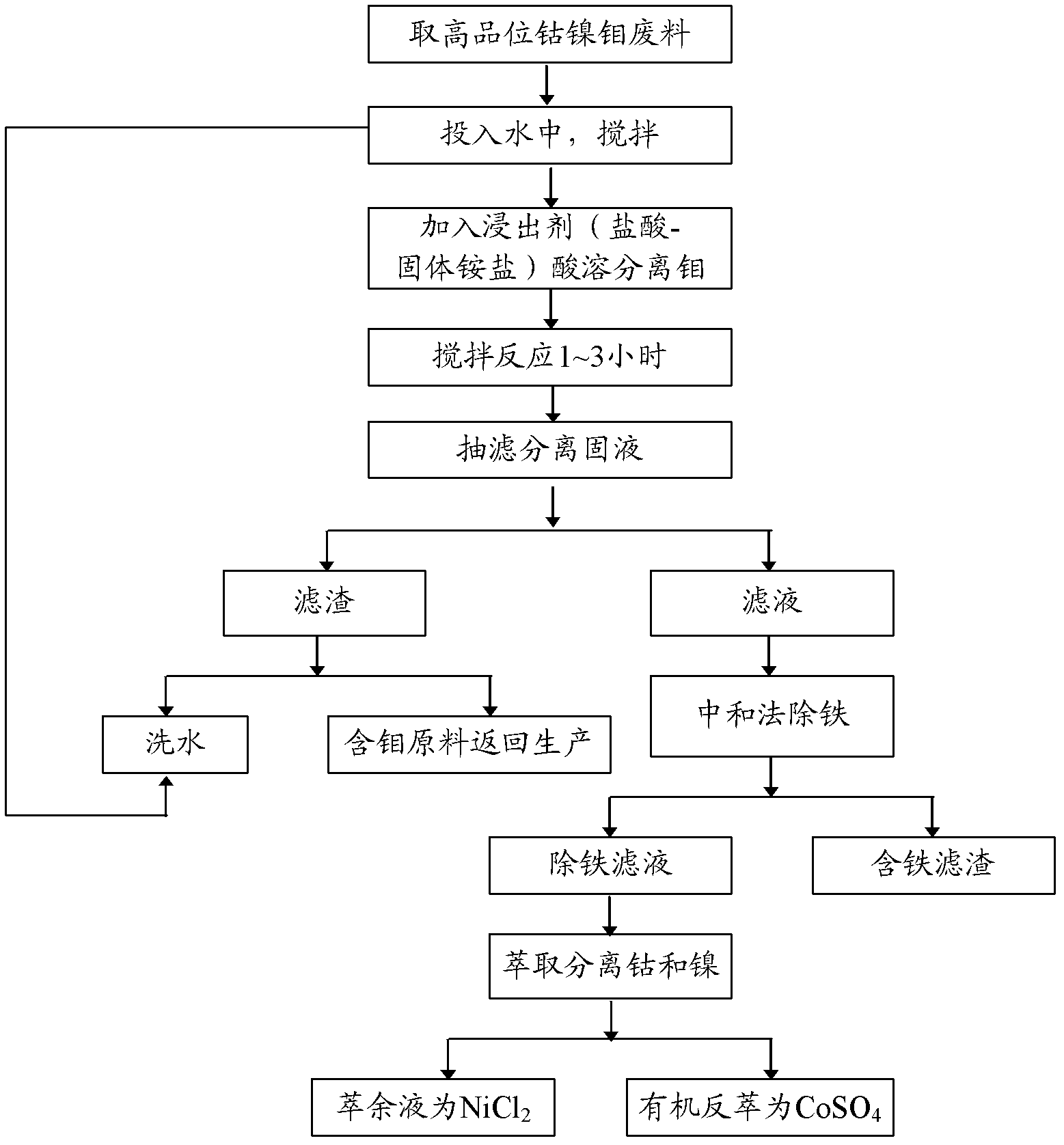

[0033] A method for selectively leaching and separating cobalt, nickel and molybdenum from high-grade cobalt, nickel and molybdenum waste materials, comprising the following steps:

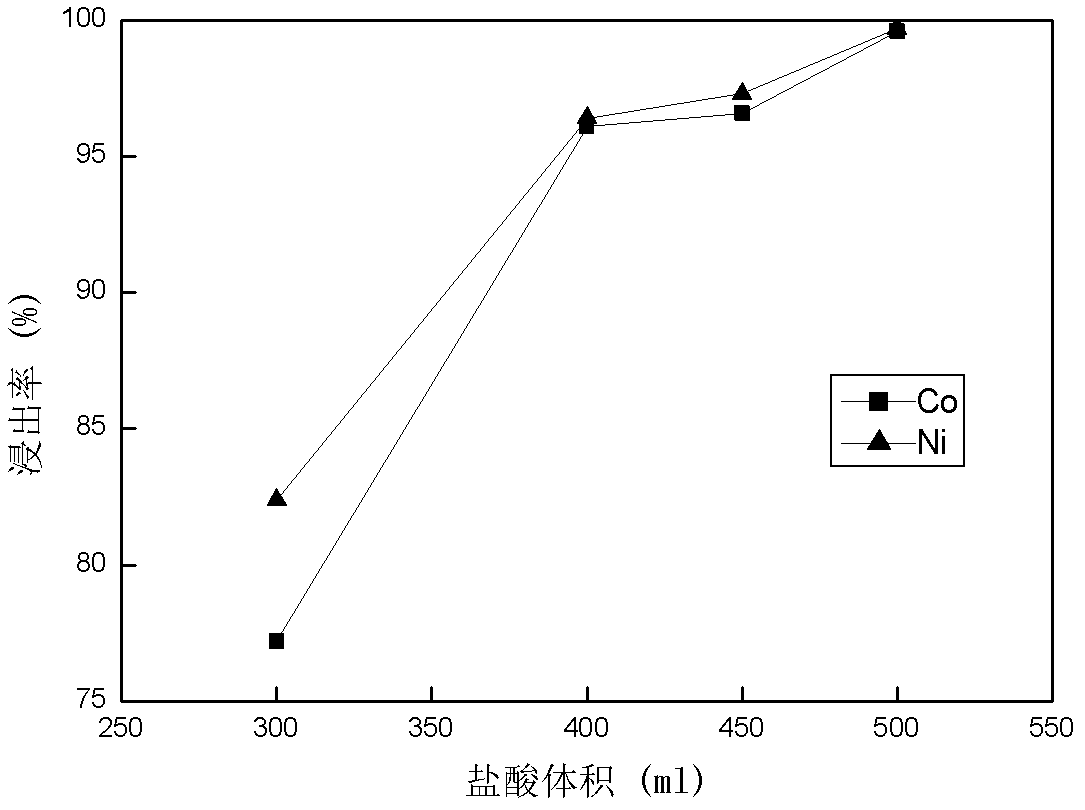

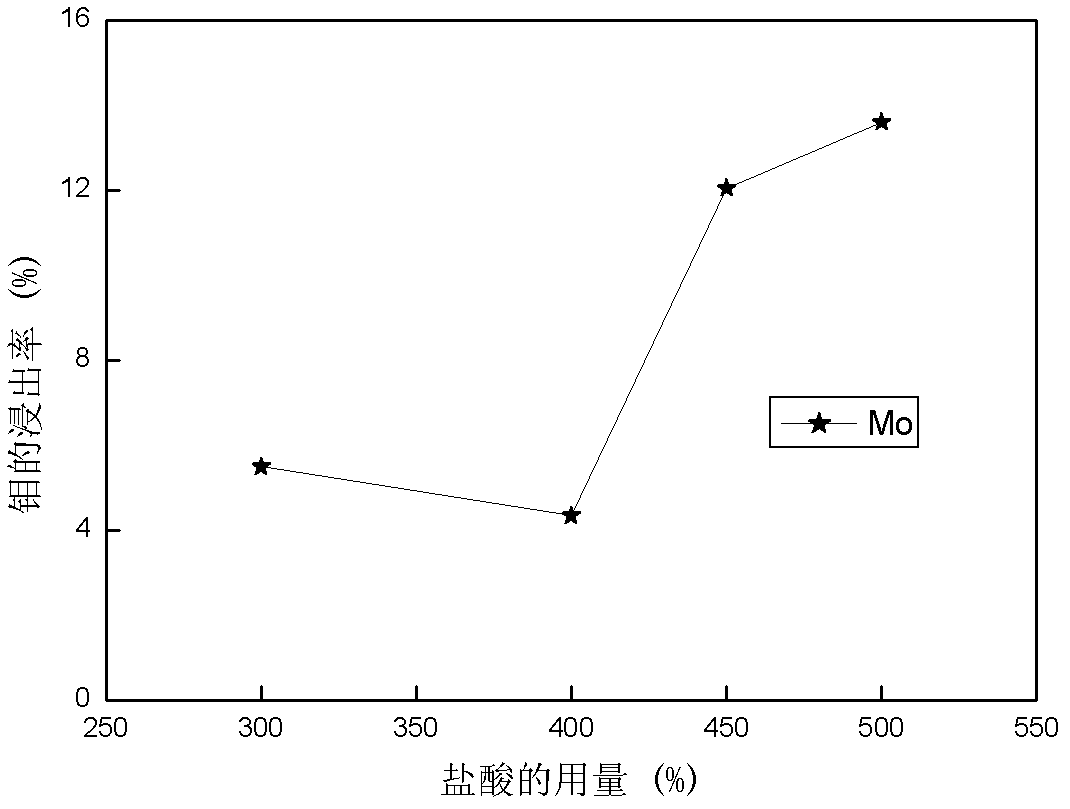

[0034] (1) Separation of molybdenum by acid-soluble method: get 100g of high-grade cobalt-nickel-molybdenum waste (from waste catalysts in the petrochemical industry, the metal content is cobalt: 24.53%, nickel: 19.1% by percentage of the total mass of cobalt-nickel-molybdenum waste , molybdenum: 10.8% and iron: 18.32%), be 1: 10 drop into water by solid-liquid ratio, stir, slowly add the concentrated hydrochloric acid that concentration is 12mol / L and ammonium nitrate carry out acid dissolution, the liquid-solid ratio of hydrochloric acid and ammonium nitrate The ratio was 1.5mL:1g, and the reaction was stirred at 85°C for 2 hours. Suction filtration, separation of solid and liquid, to obtain 820mL cobalt concentration of 26.5g / L, nickel concentration of 22.61g / L, molybdenum concentration of 445....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com