Furnace pressure control structure of rotary hearth furnace

A technology of furnace pressure control and rotary hearth furnace, which is applied to furnaces, furnace types, fluidized bed furnaces, etc., can solve the problems of increasing the heat loss of waste gas production, reducing the heat transfer of heated materials, and increasing the heat loss of waste gas, etc., to achieve Effects of clean and green production, improvement of equipment thermal efficiency, and reduction of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

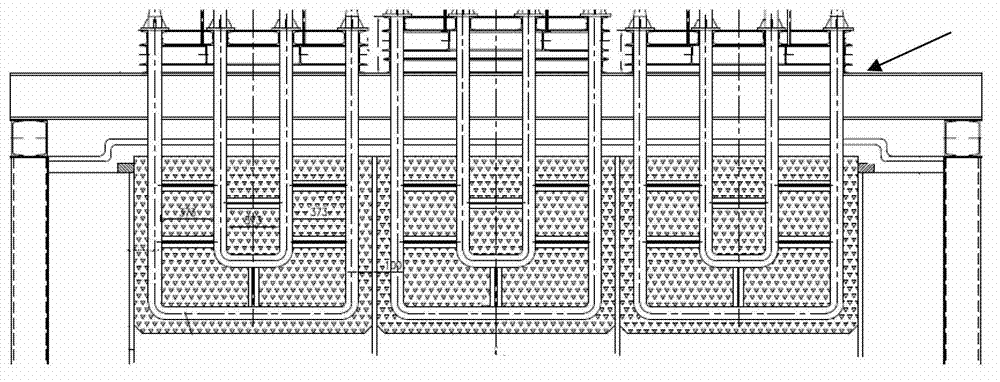

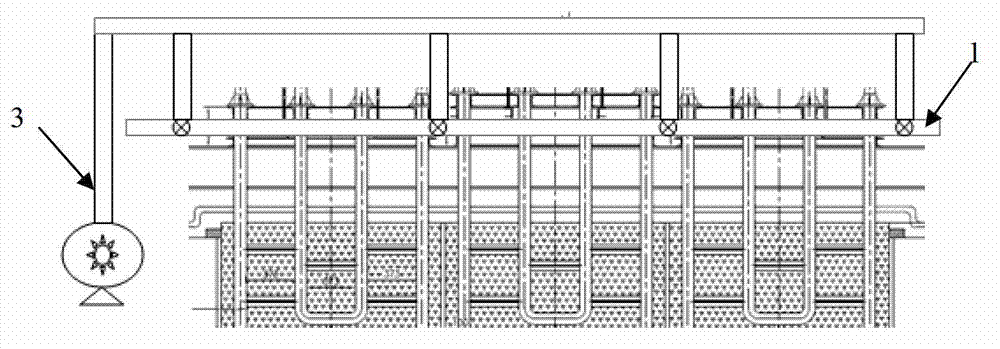

[0027] Below in conjunction with accompanying drawing of description, specific embodiment and implementation effect of the present invention will be further described:

[0028] In the example of the present invention, the rotary hearth furnace has a bottom width of 5m and an effective bottom area of 412m 2 . The effective angle of the whole furnace from the feed end to the discharge end is 330°, which is divided into preheating section, reduction I section, reduction II section, soaking section I and soaking section II, and the crossing angles of each section are 53°, 76°, 70°, 65°, 66°, the furnace heights of each section are 1.5m, 2.1m, 1.5m, 1.3m, 1.3m respectively. Since the counterflow of pellets and furnace gas can improve the gas-solid heat exchange efficiency, the furnace smoke outlet is set at the junction of the preheating section and the reduction section I, which are closer to the feed inlet.

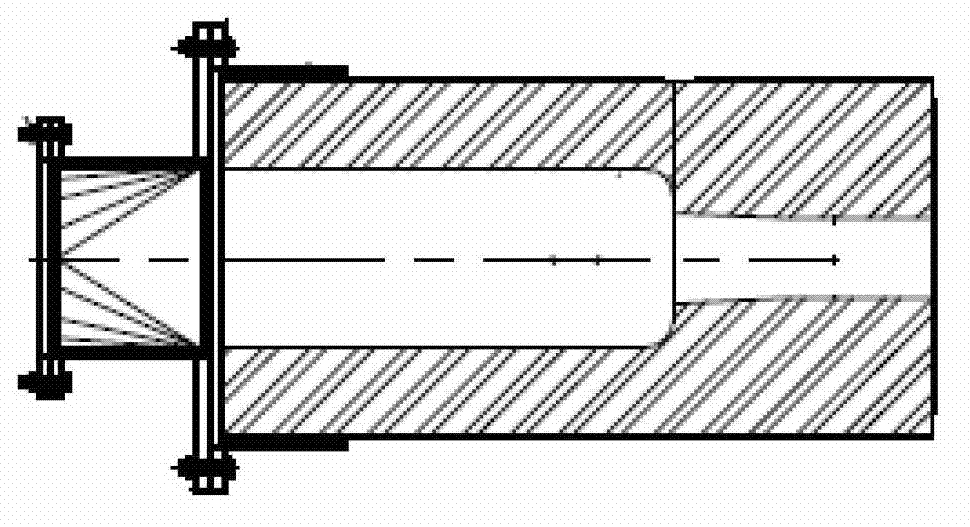

[0029] In order to adjust the furnace pressure distribution in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com