Resin system capable of realizing automatic oxidation, automatic initiation and radiation curing and preparation method thereof

A technology of radiation curing resin and auto-oxidation, applied in the preparation of organic compounds, organic chemical methods, epoxy resin coatings, etc., can solve the problems of increasing investment costs, the coating surface cannot be fully dried and enlarged, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0138] In a particularly preferred embodiment of the present invention, at least a part of the matrix resin in the autoxidisable, self-initiating, radiation-curable resin system is a component having the following formula (II):

[0139]

[0140] in,

[0141] R 1 for CH 2 =CH- or CH 2 =C(CH 3 )-;

[0142] -OCOR 1 ’ is an average iodine value of at least 100g I 2 Unsaturated fatty acid residues of unsaturated fatty acids per 100g of fatty acids, where R 1 ' is the alkenyl moiety of said unsaturated fatty acid;

[0143] R 2 Be the divalent residue with following formula (III) structure:

[0144]

[0145] in,

[0146] D stands for -S-, -S-S-, -SO-, -SO 2 -, -CO 2 -, -CO-, -O- or a divalent alkyl group having 1 to 10 carbon atoms,

[0147] Each Y represents a halogen, or optionally substituted monovalent C 1 -C 10 Hydrocarbyl,

[0148] Each m represents 0, 1, 2, 3 or 4,

[0149] n represents an integer from 0 to 4;

[0150] R 3 Indicates optionally substi...

Embodiment 1

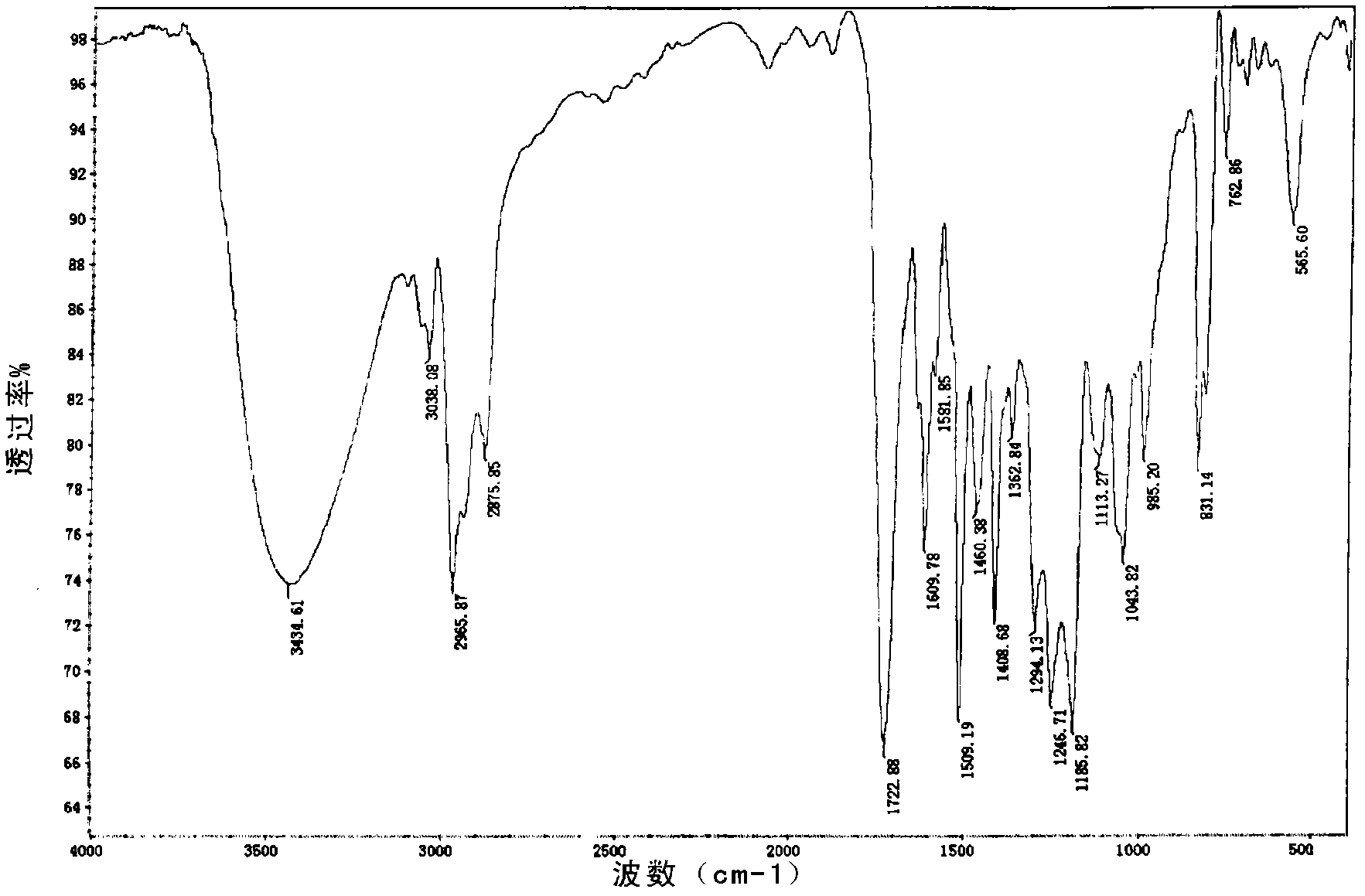

[0275] Example 1: Autoxidisable, self-initiating radiation-curable epoxy resin systems

[0276] Step a. Preparation of epoxy resin modified by autoxidisable compound, radiation curable compound

[0277] Drop into 1.16g tetramethylammonium chloride, 32.4g acrylic acid and 14.02g linoleic acid in the head tank, and mix well. Drop into 196.08g epoxy resin and 0.46g p-hydroxyanisole in reaction bottle, and mix homogeneously. Then, at a temperature of 80 to 120° C., drop the mixed solution in the header tank into the reactor. After the dropwise addition was completed, the resulting reaction mixture was kept at 80˜120° C., and the acid value of the mixture was tested. When the acid value of the reaction mixture was lower than 1 mg KOH / (g reaction mixture), the temperature was lowered to obtain an epoxy resin modified by unsaturated fatty acid and acrylic acid.

[0278] Step b. Preparation of 184 half-blocked TDI

[0279] Under the protection of nitrogen, put 0.03g of dibutylti...

Embodiment 2a

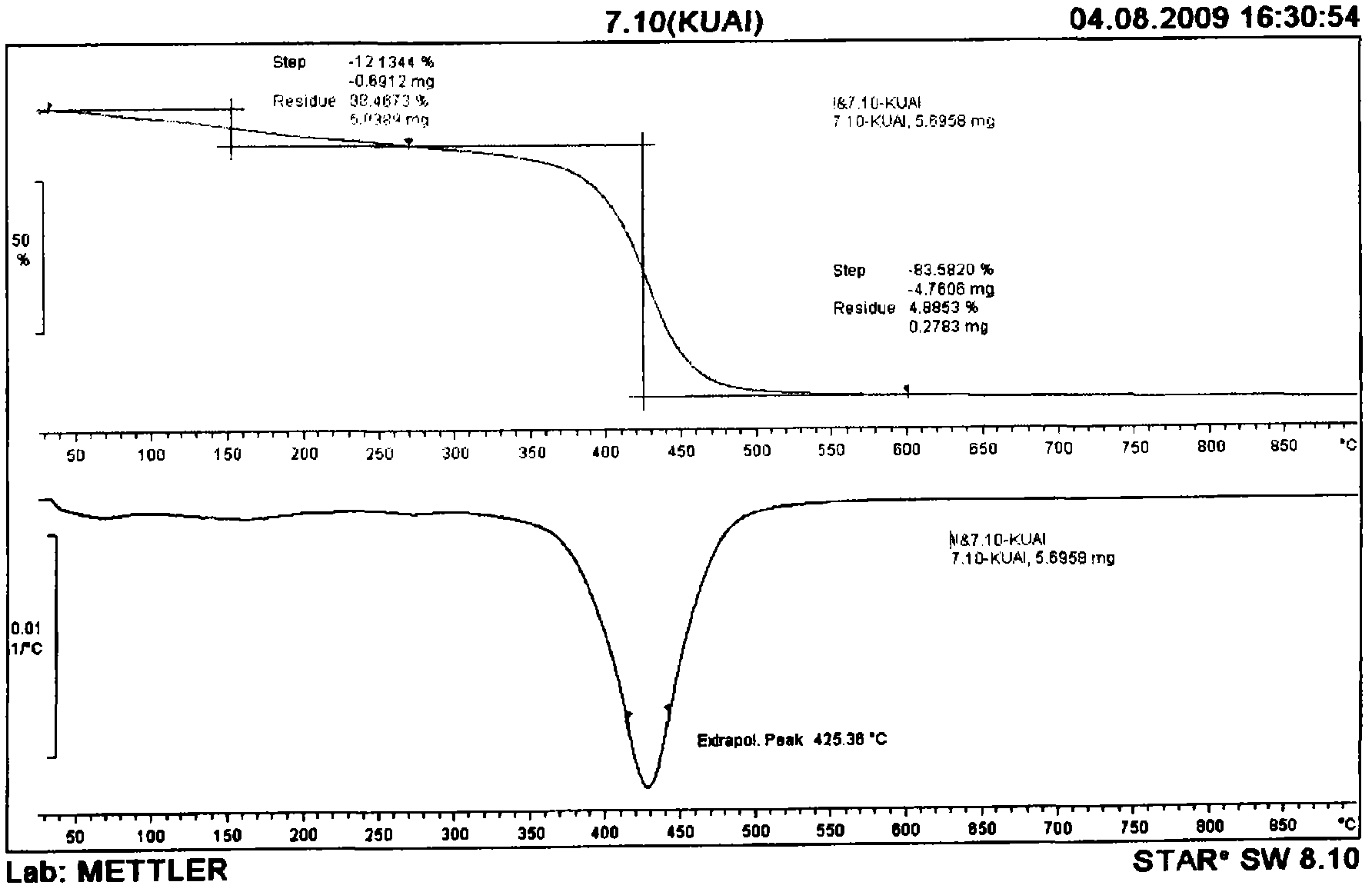

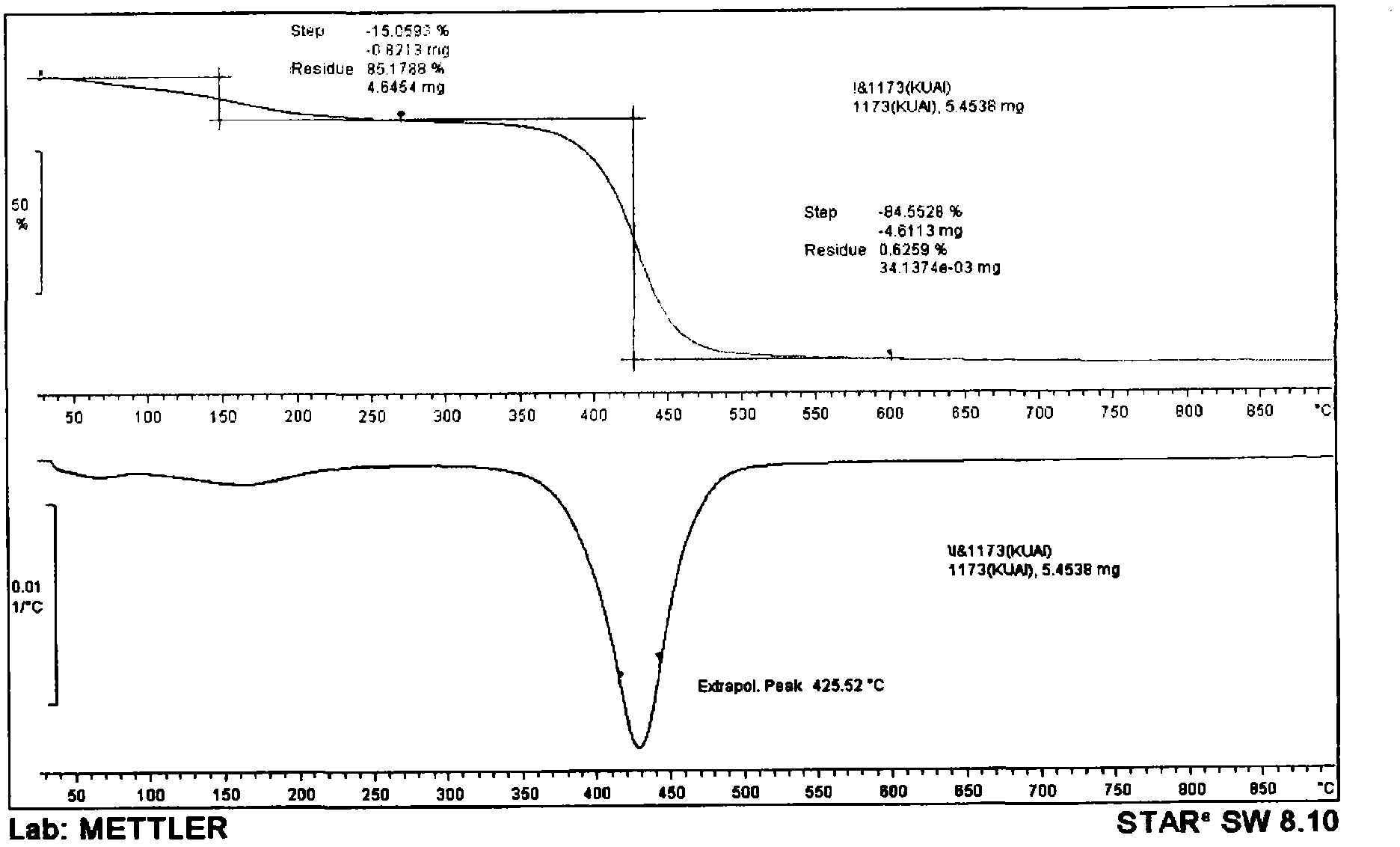

[0282] Example 2a. Determination of the properties of the autoxidisable, self-initiating radiation-curable epoxy resin systems of the present invention

[0283] The drying time, coating hardness, coating adhesion, coating flexibility, coating Layer odor, coating yellowing resistance, and coating heat loss at 25 to 270°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Iodine value | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com