Lifter for lead cup of high-position plate casting machine

A technology of casting machine and lifter, applied in the field of lifters for lead cups, can solve the problems of troublesome maintenance and replacement of lead cups, failure of normal production in workshops, deterioration of quality of cast sheets, etc., so as to ensure production continuity and performance. , the effect of increasing the positivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

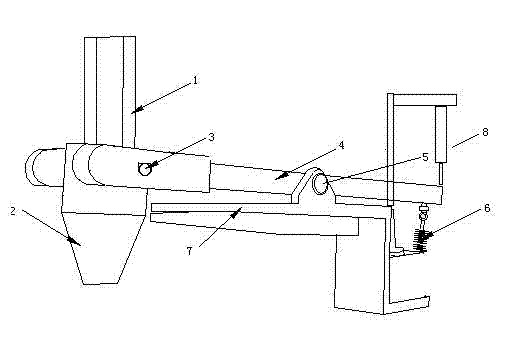

[0009] like figure 1 As shown, the lead cup 2 is located below the lead pipe 1, and is characterized in that: a lifter is installed on the lead cup 2, and the lifter includes a lever 4, a spring 6, a fixed plate 7 and a cylinder 8, and two levers 4 The middle part of the guide post 5 is installed on the fixed plate 7, and stainless steel rods 3 are respectively welded on both sides of the lead cup 2. The stainless steel rod 3 is engaged with the front end of the lever 4, and the tail end of the lever 4 is connected to the fixed plate 7 through the spring 6. The afterbody of fixed plate 7 is installed cylinder 8.

[0010] Its working principle is: cylinder 8 is pressed down, and the front end of lever 4 is pushed up, thereby lead cup 2 pushes up once, and the lead pipe 1 is blocked; then cylinder 8 retracts, spring 6 resets, and lever forms a reset action.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com