Buckling restrained brace large cantilever structure system

A technology of buckling beam bracing and large cantilever, applied in building components, building structures, building types, etc., can solve problems such as easy buckling, reduced bearing capacity and stiffness, and achieve stable hysteretic performance and increased stability. And deformation ability, good effect of anti-seismic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

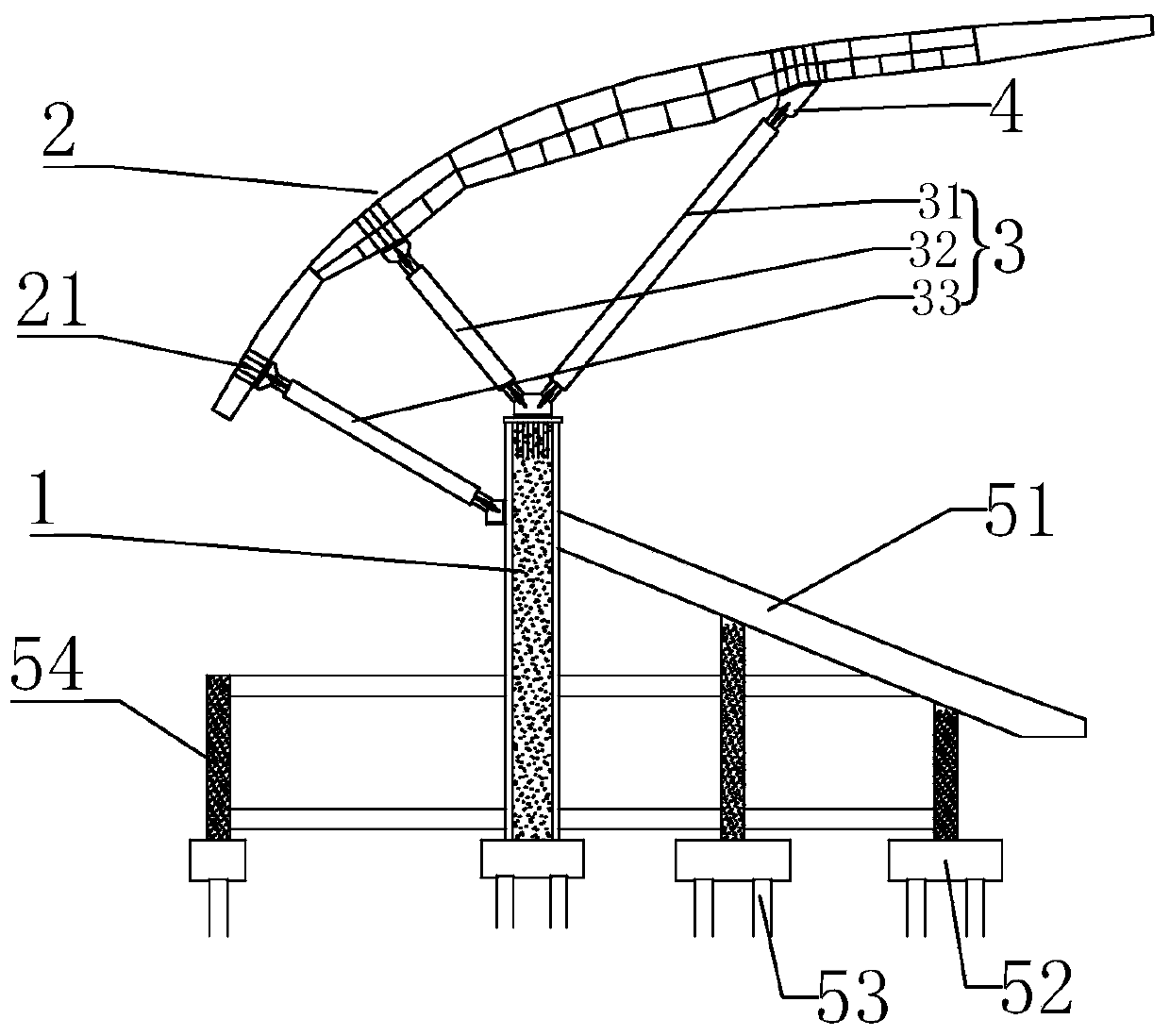

[0032] Such as Figure 1-3 As shown, a large cantilevered structure system supported by the buckling restraint system includes a concrete composite column 1, a special-shaped cantilever beam 2 and a buckling restraint support 3 arranged between the concrete composite column 1 and the special-shaped cantilever beam 2; The concrete composite column 1 and the buckling bundle support 3, the special-shaped cantilever beam 2 and the buckling bundle support 3 are all connected by a fabricated metal connector 4.

[0033] The flexion restraint support 3 at least includes a first flexion restraint support 31, a second flexion restraint support 32, and a third flexion restraint support 33 each connected to the concrete composite column 1 at one end; The flexion restraint support 31 and the third flexion restraint support 33 are respectively provided on two sides of the second flexion restraint support 32 along the cantilever direction of the cantilever beam; the other end of the first flexi...

Embodiment 2

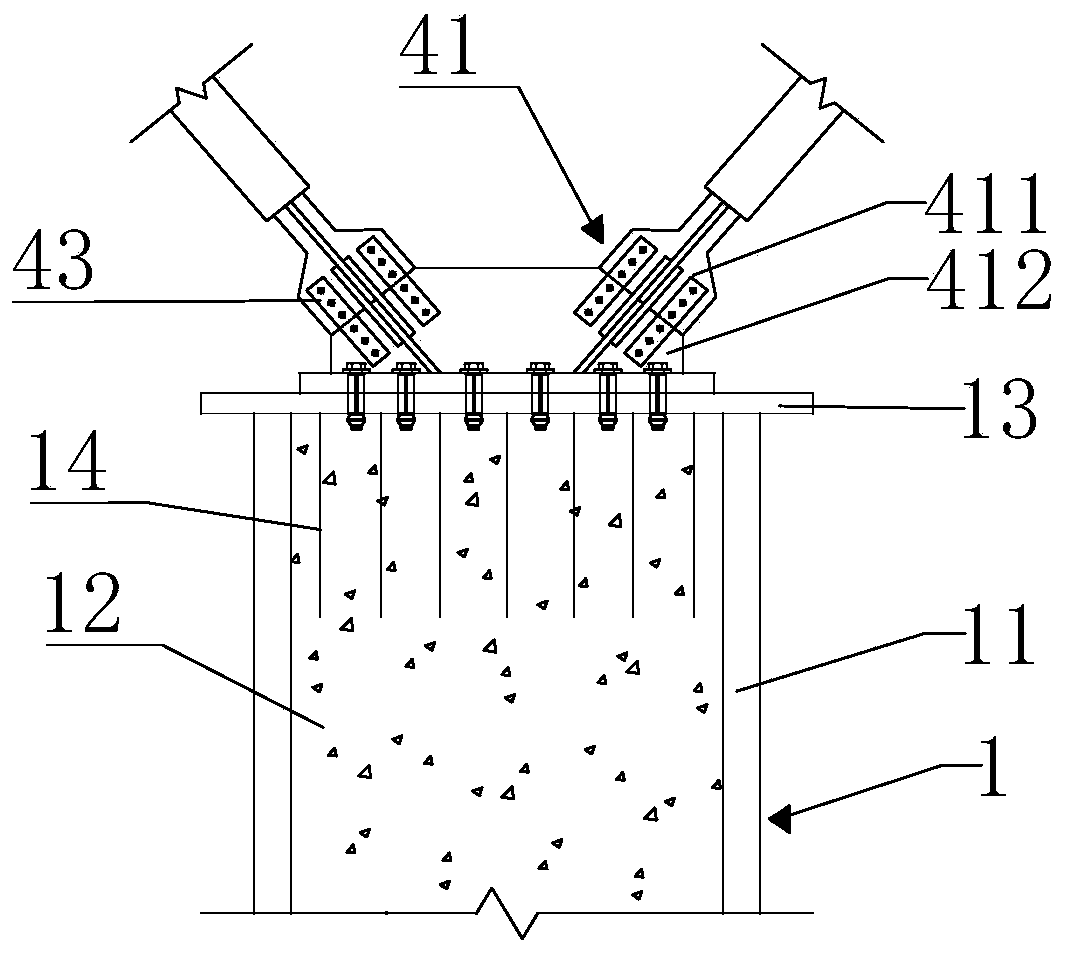

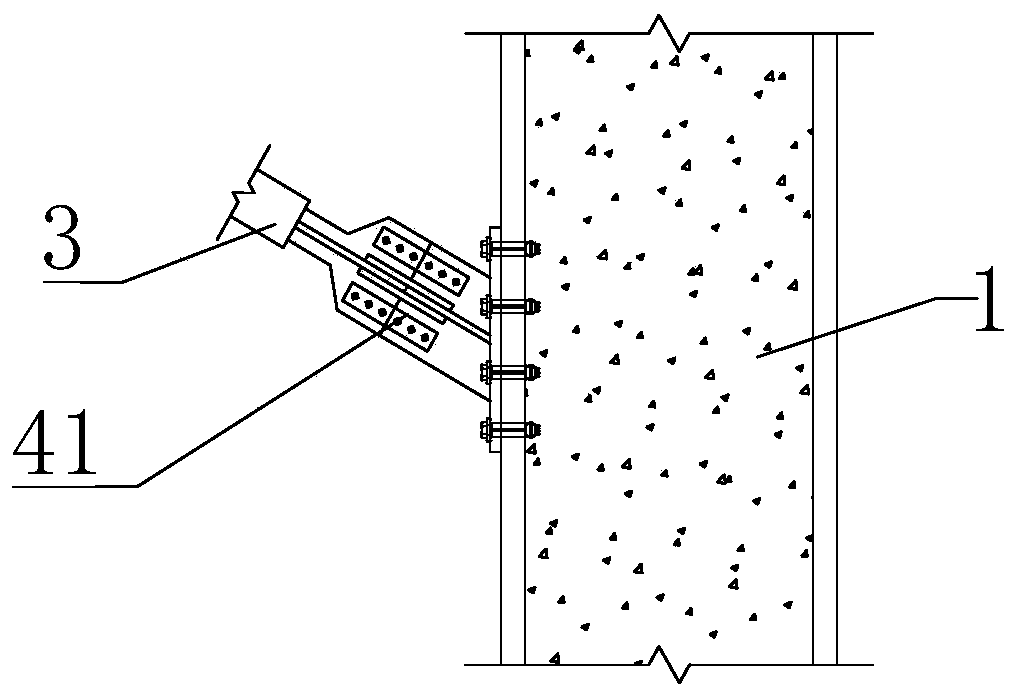

[0036] Such as Figure 4 , 5 As shown, on the basis of Embodiment 1, the fabricated metal connector 4 includes a composite column connector 41 and a cantilever beam connector 42; the composite column connector 41 connects the concrete composite column 1 with the buckling beam system Support 3, the cantilever beam connector 42 connects the special-shaped cantilever beam 2 and the buckling restraint support 3; the combined column connector 41 includes a first connector 411 and a second connector 412 that cooperate with each other; One end of the first connecting piece 411 is matched with one end of the second connecting piece 412; the other end of the first connecting piece 411 is fixed to the buckling restraint support 3, and the other end of the second connecting piece 412 is combined with concrete The column 1 is fixed; the cantilever beam connector 42 includes a third connector 421 and a fourth connector 422 that cooperate with each other; one end of the third connector 421 is...

Embodiment 3

[0039] On the basis of Example 2, the concrete composite column 1 includes a square-section steel column 11, concrete 12 poured into the square-section steel column 11, an energy-consuming metal plate 13 welded to the top of the square-section steel column 11, and one end and The energy-consuming metal plate 13 is fixed, and the other end is embedded in the embedded part 14 inside the concrete 12.

[0040] The first flexion-beam support 31 and the second flexion-beam support 32 are both connected to the energy-dissipating metal plate 13 on the top of the concrete composite column 1 through a composite column connector 41; the third flexion support 33 The composite column connector 41 is connected to the side wall of the concrete composite column 1; the composite column connector 41 is connected with the energy-consuming metal plate 13, and the composite column connector 41 is connected with the side wall of the concrete composite column 1 by blind bolts.

[0041] The first connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com