High-current cage type belt spring inserting hole

A high-current, cage-type technology, applied in the direction of circuits, electrical components, coupling devices, etc., can solve the problems of detachment, unsupported live plugging, cost increase, etc., and achieve stable dynamic contact resistance, simple and standardized structure, easy management and The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

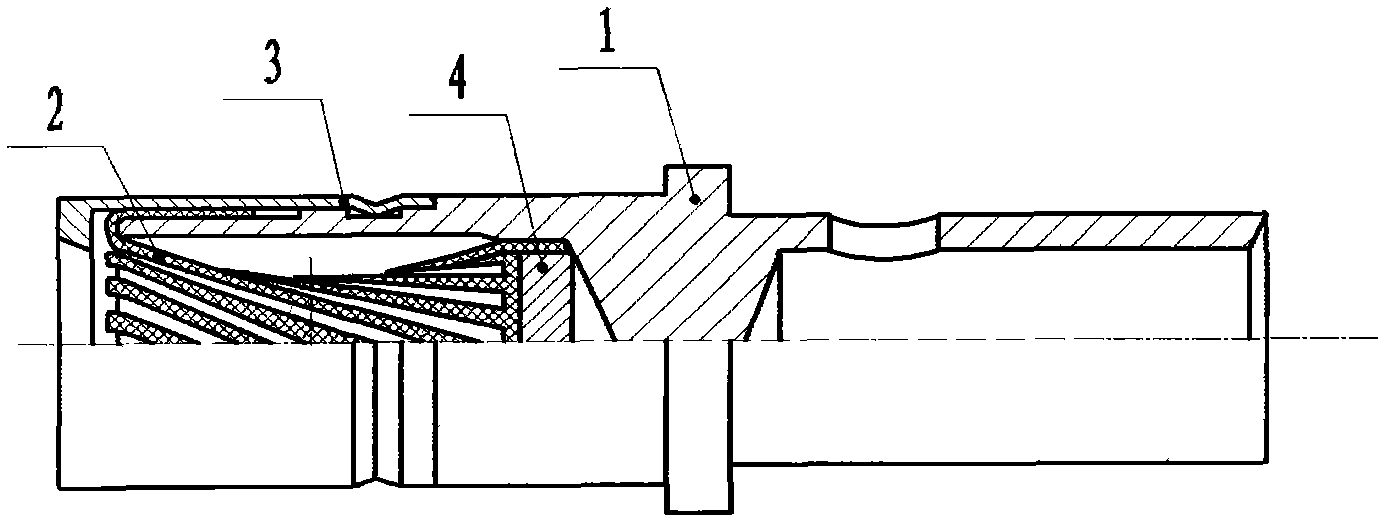

[0019] figure 1 It is a structural schematic diagram of a high-current cage-type spring jack, which is characterized in that a comb-shaped metal sheet 2 composed of a group of elastic metal strips connected at one end and having a specific inclination angle with the end face is installed in the jack body 1. Shaped metal sheet 2 is formed by punching and splitting a certain length of elastic metal sheet according to requirements, cuts the required length according to the size of the socket specification, and crimps the connected end into the socket body 1 . Due to the elasticity of the comb-shaped metal sheet 2 , the connected end is tightly supported on the inner wall of the socket body 1 , and the fixed piece 4 is tightly supported on the inner wall of the socket body 1 .

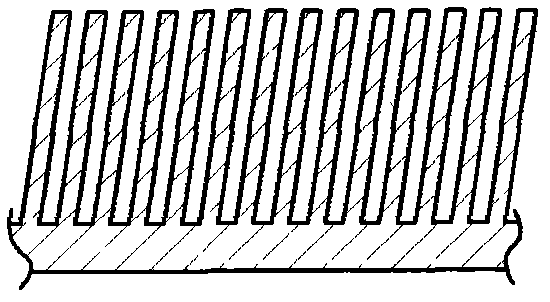

[0020] figure 2 Schematic diagram of a comb-like metal sheet.

[0021] Since each elastic metal strip of the comb-shaped metal sheet 2 has a specific inclination angle, and the outward ends are not conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com