Method for determining mercury content in textile auxiliary through microwave digestion-atomic fluorescence spectrophotometry

A technology of textile auxiliaries and atomic fluorescence, which is applied in the field of microwave digestion-atomic fluorescence spectrophotometry (AFS) to determine the mercury content in textile auxiliaries, can solve the problems of low sensitivity detection limit and achieve high sensitivity, low detection limit, Analyzing fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

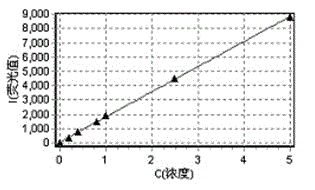

Image

Examples

Embodiment 1

[0047] Sample: water-based flame retardant adhesive TF-681, suspension, industrial product, produced by Zhejiang Transfar Co., Ltd.

[0048] 1. Sample pretreatment method

[0049]1. Preparation of test solution

[0050] Weigh 0.2502g sample of water-based flame retardant adhesive TF-681, place it in a microwave digestion tube, add 3 mL nitric acid (mass concentration 65-68%), 2 mL hydrogen peroxide (mass concentration 30%), 2 mL fluoroboric acid (mass concentration 49.5~50.5%), after covering the safety valve, put the digestion tube into the microwave digestion instrument, and keep it at 195°C for 15 minutes. After the solution was cooled to room temperature after digestion, the solution was transferred to a 25 mL volumetric flask, made up to volume with deionized water, and filtered through a water membrane before use.

[0051] Take 5.00 ml of digestion solution, dilute to 10.00 ml with water, shake well and let it stand for 1 hour, the test solution is to be tested.

[00...

Embodiment 2

[0095] Sample: salt-resistant high-temperature leveling agent TF-212B, brown solution, industrial product, produced by Zhejiang Transfar Co., Ltd.

[0096] 1. Sample pretreatment method

[0097] 1. Preparation of test solution

[0098] Weigh 0.2003g sample of salt-resistant high-temperature leveling agent TF-212B, place it in a microwave digestion tube, add 3 mL nitric acid (mass concentration 65~68%), 2 mL hydrogen peroxide (30%), 2 mL fluoroboric acid (mass concentration 49.5~50.5%), after covering the safety valve, put the digestion tube into the microwave digestion instrument, and keep it at 190°C for 20 minutes. After the solution was cooled to room temperature after digestion, the solution was transferred to a 25 mL volumetric flask, made up to volume with deionized water, and filtered through a water membrane before use.

[0099] Take 5.00 ml of digestion solution, dilute to 10.00 ml with water, shake well and let it stand for 1 hour, the test solution is to be tested...

Embodiment 3

[0131] Sample: fluorescent whitening agent TF-351, yellow-green suspension, industrial product, produced by Zhejiang Transfar Co., Ltd.

[0132] 1. Sample pretreatment method

[0133] 1. Preparation of test solution

[0134] Weigh 0.3000g fluorescent whitening agent TF-351 sample, put it in a microwave digestion tube, add 3 mL nitric acid (mass concentration 65~68%)), 2 mL hydrogen peroxide (mass concentration 30%), 2 mL fluorine Boric acid (mass concentration 49.5~50.5%), after covering the safety valve, put the digestion tube into the microwave digestion apparatus, and keep it at 200°C for 10 minutes. After the solution was cooled to room temperature after digestion, the solution was transferred to a 25 mL volumetric flask, made up to volume with deionized water, and filtered through a water membrane before use.

[0135] Take 5.00 ml of digestion solution, dilute to 10.00 ml with water, shake well and let it stand for 1 hour, the test solution is to be tested.

[0136] 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| correlation coefficient | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com