Three-degree-of-freedom self-walking minitype shield machine

A technology of shield machine and degree of freedom, which is applied in mining equipment, earthwork drilling, tunnels, etc. It can solve the problems of poor comprehensive drainage, low extraction rate of mine, and short drilling length, so as to achieve sufficient gas discharge, The effect of high utilization rate and low cost of drilling engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

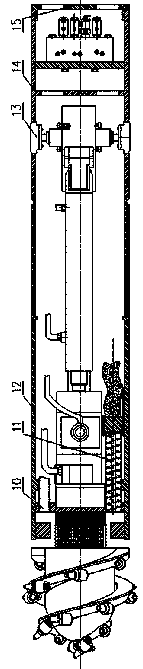

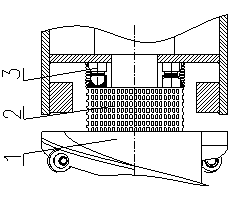

[0012] The three-degree-of-freedom self-propelled miniature shield machine of the present invention mainly consists of a shield machine cutting head 1, a secondary crushing mechanism 2, an angle adjustment cylinder 3, a hydraulic motor 4, a front support cylinder 5, an inner support 6, and a propulsion cylinder 7. Outer support 8, hydraulic valve group 9, water delivery device 10, screw conveyor 11, front shield 12, rear support oil cylinder 13, middle shield 14, tail shield 15 constitute. The front shield 12 is matched with the middle shield 14 sliding sleeve. The front shield 12 is provided with an I-shaped inner bracket 6, the middle shield 14 is provided with an outer bracket 8 connected with the inner bracket 6, and the front end of the inner bracket 6 is provided with a hydraulic motor 4. The front part of the motor 4 is provided with a shield machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com