Crane sling power generation system, crane sling and crane

A power generation system and crane technology, which is applied to cranes, motor/generator/inverter limiters, motor generator control, etc., can solve the problems of affecting the operating performance of cranes, reducing the service life of cables, and illegal and complicated wiring arrangements. , to achieve the effects of reducing oil pollution, increasing power generation capacity, and saving fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

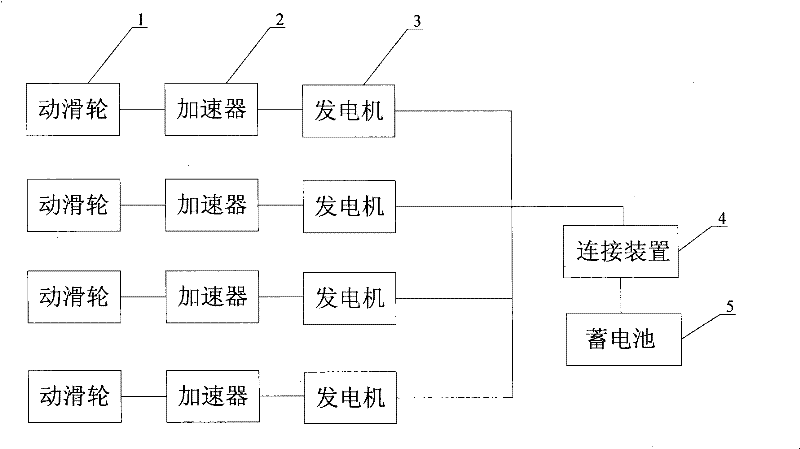

[0029] Embodiment 1 provides a crane spreader power generation system, combined with figure 1 with figure 2 , the crane spreader power generation system provided includes four movable pulleys 1, an accelerator 2, a generator 3, a connecting device 4 and a storage battery 5, and for the convenience of description, a spreader frame 100 is also shown in the figure. The movable pulley 1 is installed on the spreader frame 100 and can rotate around a fixed shaft; the four movable pulleys 1 form the movable pulley block of the crane, and the movable pulley block and the fixed pulley block can form the pulley mechanism of the crane to realize the rise and fall of the spreader. Corresponding to each movable pulley 1, four accelerators 2 are installed, and the accelerators 2 are installed between the rotating shaft of the movable pulley 1 and the rotor shaft of the generator 3. In this example, the accelerator 2 is a planetary accelerator, and its two ends are respectively connected w...

Embodiment 2

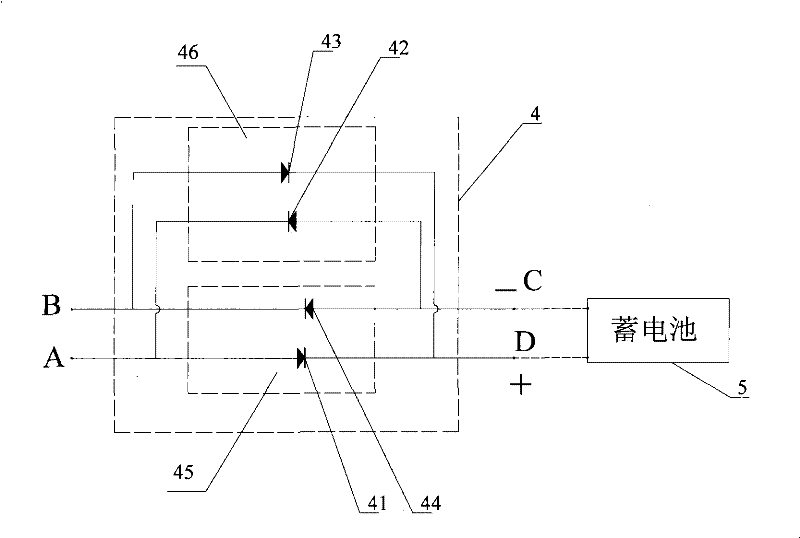

[0036] The working process of the crane spreader power generation system provided by Embodiment 2 is: when the battery 5 is fully charged, the travel switch 47 keeps the second one-way circuit 46 in the disconnected state, and the second one-way circuit 46 cannot connect the generator 3 to the battery. connected, the second one-way circuit 46 does not work; at this time, only the first one-way circuit 45 remains connected. When the sling is raised, the second output terminal B of the generator 3 is a high-voltage terminal, the first output terminal A is a low-voltage terminal, the diode of the first one-way circuit 45 is reversely cut off, the generator 3 cannot charge the storage battery 5, and the storage battery 5 Also can not discharge; When the sling is lowered, the first output terminal A of the generator 3 is a high-voltage terminal, the second output terminal B is a low-voltage terminal, and the diode of the first one-way circuit 45 is forward-conducting, so that the ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com