Solid wood structural geothermal floor

A technology of geothermal floor and structure, which is applied in the direction of building structure, floor, building, etc., can solve the problems that affect the service life of the solid wood geothermal floor, bulging, twisting, loosening and cracking, low moisture content of the floor, etc., and achieve lateral expansion The effect of reducing shrinkage and shrinkage, luxury comfort, and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

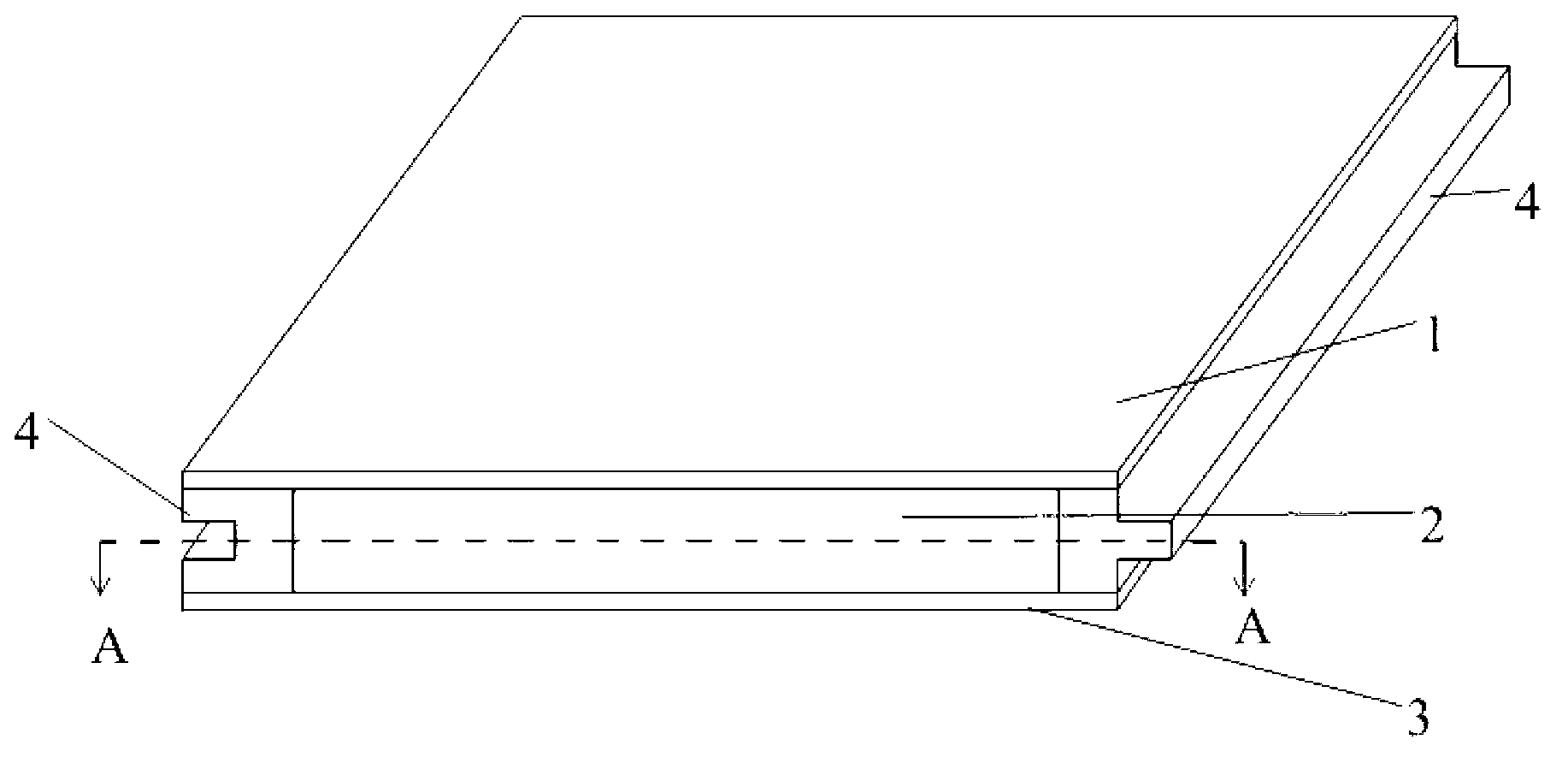

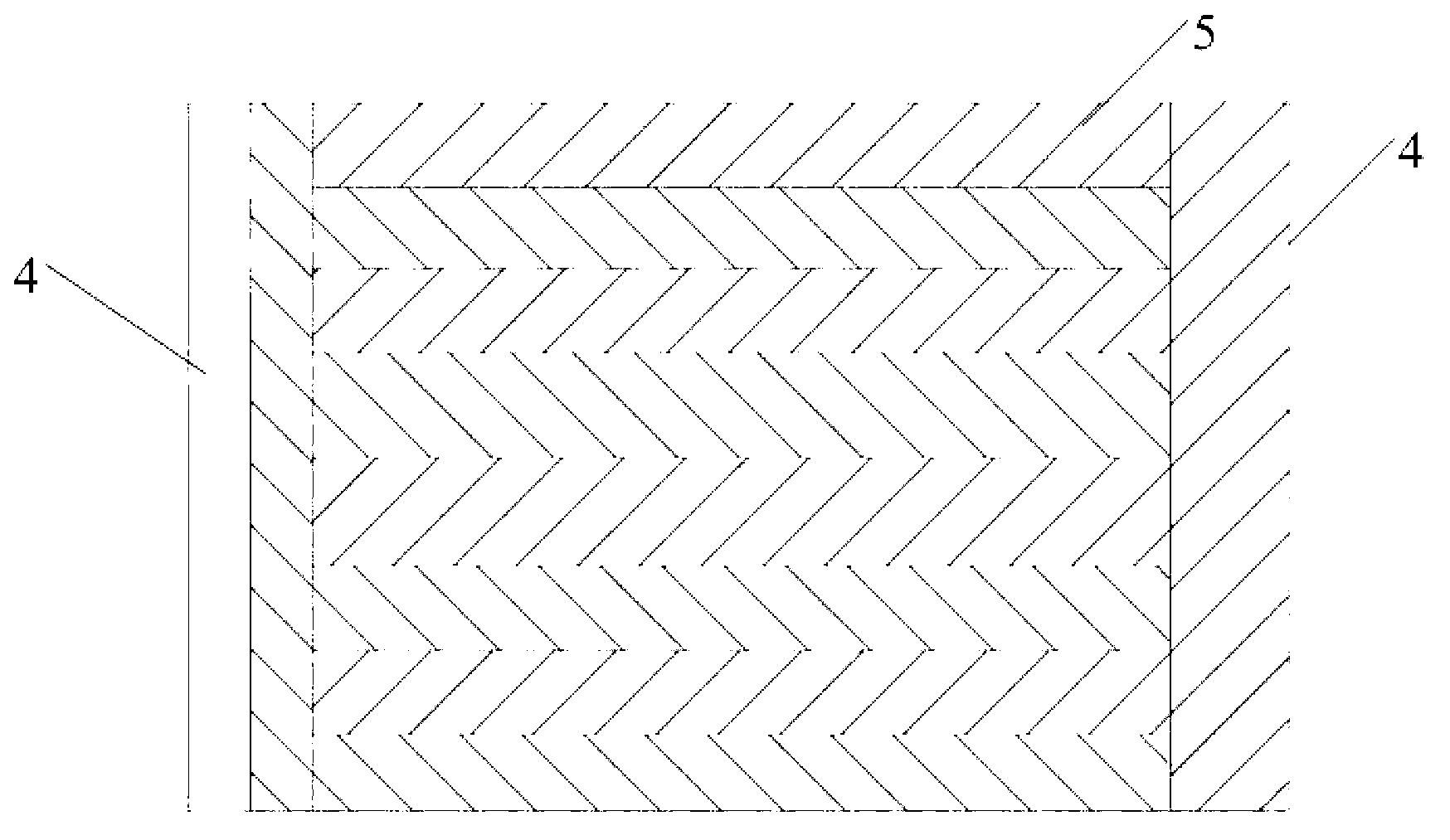

[0016] Such as figure 1 As shown, the present invention provides a geothermal floor with solid wood structure, including a surface layer 1, an inner layer 2 and a bottom layer 3, wherein the surface layer 1 may also be provided with a decorative layer, and the inner layer 2 is formed by joining several horizontal planks 5 , so that the lateral expansion rate and shrinkage rate of the inner layer 2 can be greatly reduced, so that the floor does not produce bulges, distortions, looseness or cracks, etc., thus prolonging the service life of the floor. Described inner layer 2 longitudinal left and right sides are respectively provided with tongue and groove plank 4, and described tongue and groove plank 4 and described inner layer 2 are glued together mutually, and what tongue and groove plank 4 adopts is high-grade wood, can guarantee like this t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com