Anti-deformation pouring mold for building supporting column and pouring construction method thereof

A support column and anti-deformation technology, which is applied in the direction of construction, building structure, formwork/formwork/work frame, etc., can solve the problems of bulge on the surface of the column and affect the pouring quality of the column, so as to improve the quality of pouring and improve the application Range, an effect that increases edge strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

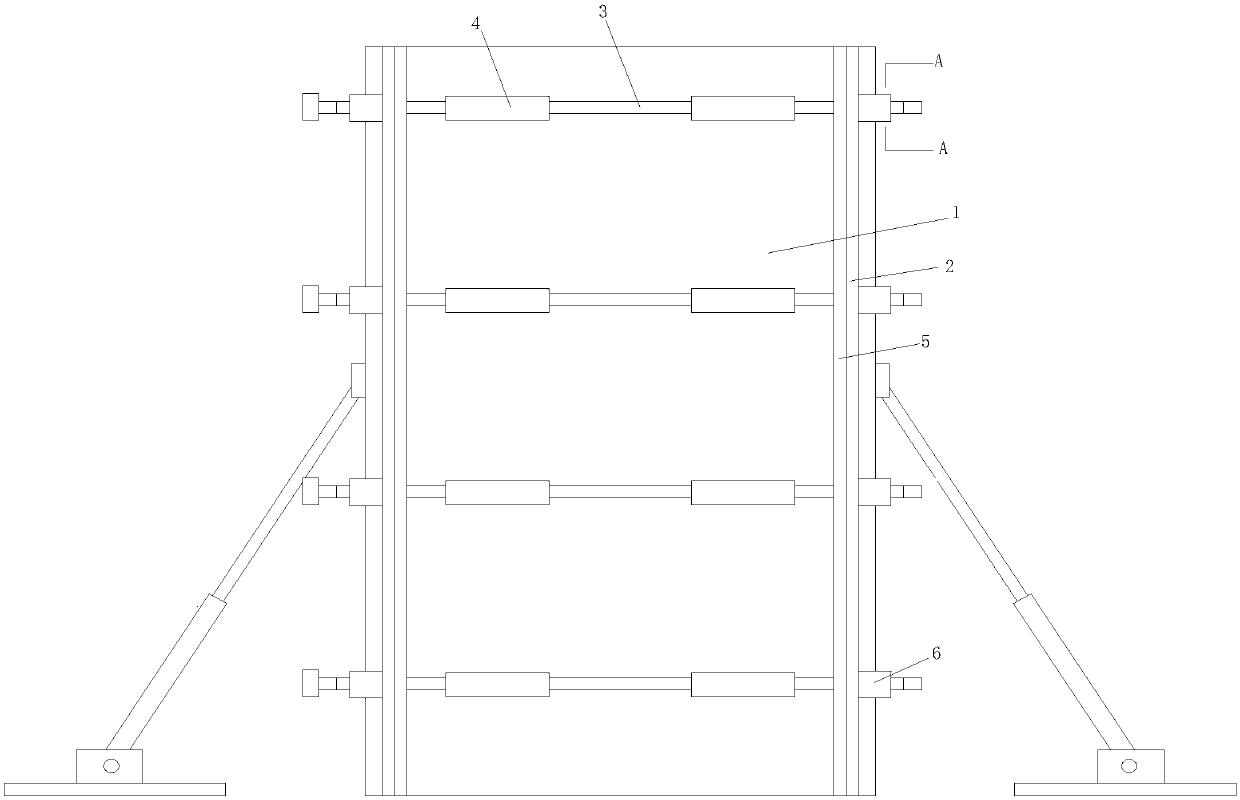

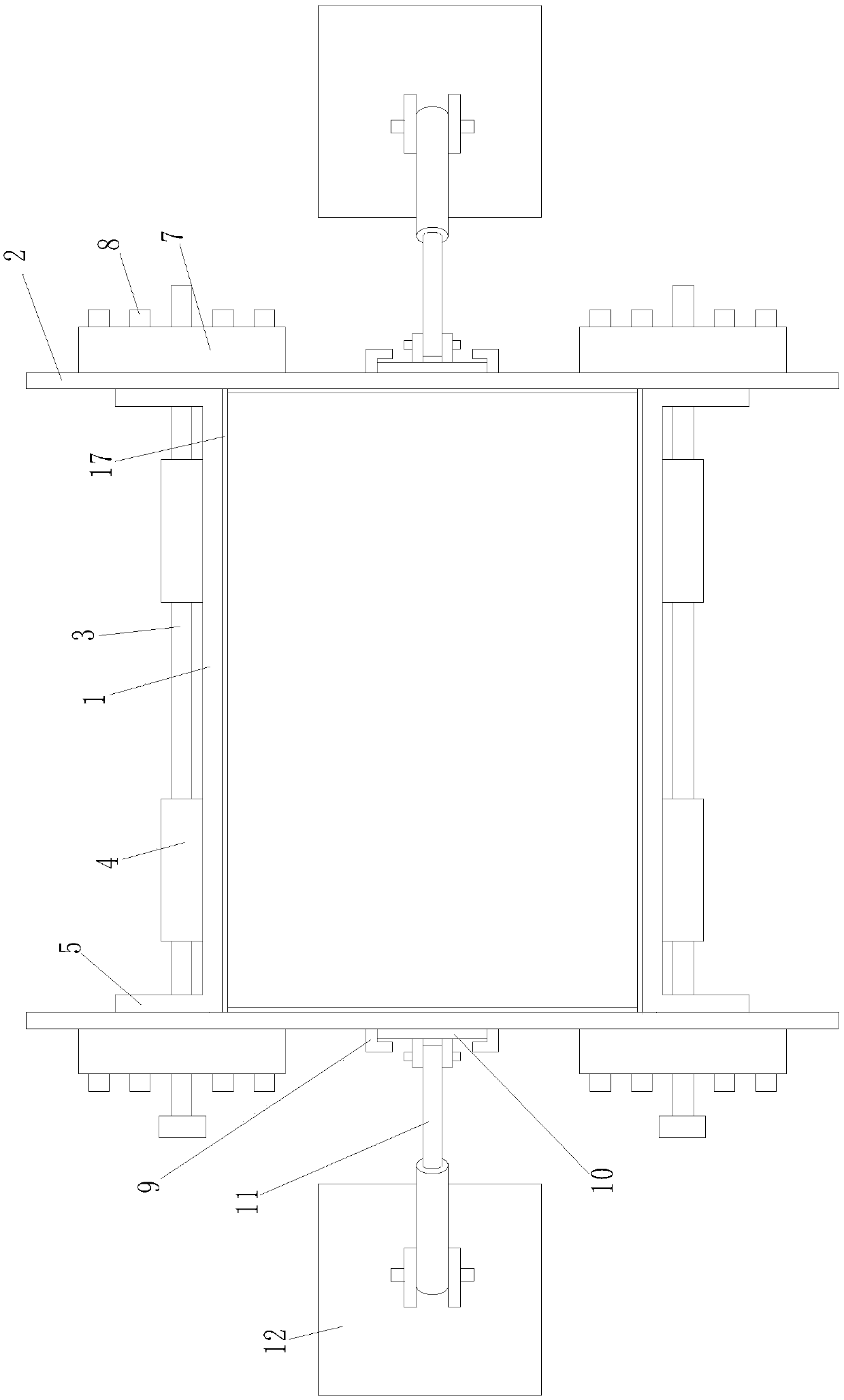

[0040] Such as Figure 1-Figure 3 As shown, the present invention is an anti-deformation pouring form for building support columns, which includes two parallel inner formworks 1 and two parallel outer formworks 2, the two inner formworks 1 and two outer formworks 2 form a prism shaped pouring space, the inner formwork 1 is set between two outer formworks 2 and is perpendicular to the outer formwork 2, the side edge of the inner formwork 1 is in contact with the outer formwork 2; the outer surface of the outer formwork 2 is provided with an inner formwork The fixed support assembly, the inner formwork fixed support assembly passes through the outer plate and is fixedly connected with the outer surface of the inner formwork 1; the outer formwork support assembly is arranged on the outer surface of the outer formwork 2, and the outer formwork support assembly extends along the length of the outer formwork 2 Orientation settings.

[0041] In the technical solution of the present ...

Embodiment 2

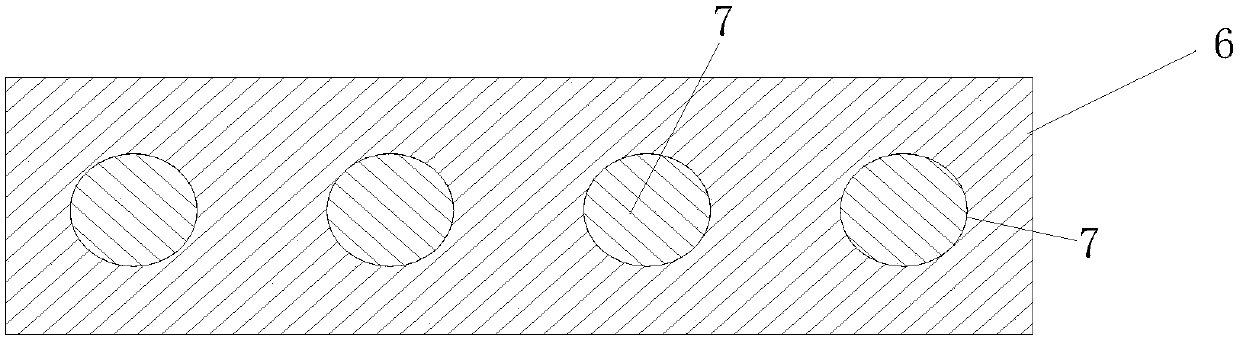

[0059] picture Figure 4-Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the outer formwork support assembly includes several parallel outer plate support rods 13 and several U-shaped buckles 14, and the two ends of the U-shaped opening of the U-shaped buckles 14 are connected to the outer formwork. The outer surface of 2 is fixedly welded, and the outer plate support rod 13 is sleeved in the U-shaped opening of the U-shaped buckle 14 and attached to the outer surface of the outer template 2 .

[0060] In the present application, the outer plate support bar 13 is fixed on the surface of the outer formwork 2 through the U-shaped buckle 14, and the outer plate support bar 13 forms an external support skeleton on the outer side of the outer formwork 2, which improves the strength of the outer formwork 2 and prevents the outside Formwork 2 deformed during pouring.

[0061] The two ends of the outer formwork 2 are respectively provided with a fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com