Preparation method for composite modified facing protective layer, and power generation building material containing composite modified facing protective layer

A composite modification and protective layer technology, which is applied to the device, coating, special surface and other directions of coating liquid on the surface, which can solve the problems of unsightly surface, poor water resistance, light transmittance and haze, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

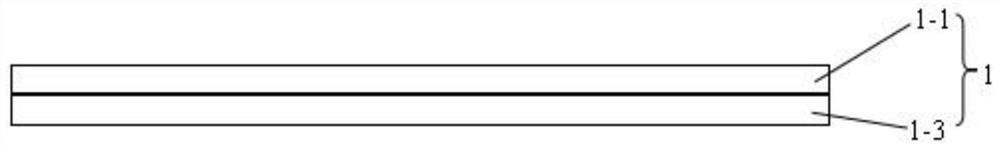

[0041] The present embodiment 1 provides a kind of preparation method of composite modified finishing protective layer, and described preparation method comprises the following steps:

[0042] (1) Spray the bottom layer 1-3 material on the carrier and bake it;

[0043] (2) Spraying the surface layer 1-1 material on the bottom layer 1-3 and baking;

[0044]Both the bottom layer material and the surface layer material are made of inorganic light diffusing agent and water glass, and the mass ratios of the inorganic light diffusing agent and water glass in the bottom layer material and the surface layer material are different, and in the bottom layer material and the surface layer material Inorganic light diffusing agents have different particle sizes. The carrier includes: inorganic glass, organic glass, transparent ceramics, glass ceramics and the like. The material characteristics of the light diffusing agent are: absorbed light ≤ 5%, reflected light ≤ 5%, and most of the lig...

Embodiment 2

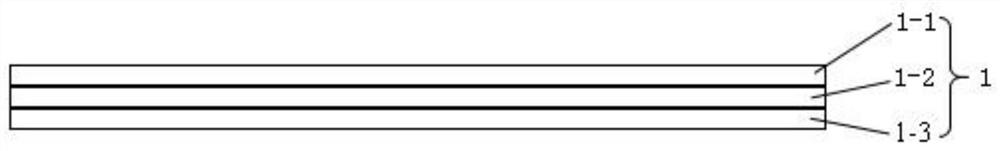

[0049] The middle layer 1-2 is added between the bottom layer 1-3 and the surface layer 1-1 of the finish protection layer, and this embodiment 2 provides a preparation method of a composite modified finish protection layer, the preparation method comprising The following steps:

[0050] (1) Spray the bottom layer 1-3 material on the carrier and bake it;

[0051] (2) Spraying the middle layer 1-2 material on the bottom layer (1-3) and baking;

[0052] (3) Spray and bake the surface layer 1-1 material on the middle layer (1-2).

[0053] The bottom layer material, the middle layer material and the surface layer material are all made of inorganic light diffusing agent and water glass, the bottom layer material, the mass ratio of inorganic light diffusing agent and water glass in the middle layer material and the surface layer material are different, the bottom layer The particle size of the inorganic light diffusing agent in the material and the surface layer material is differ...

Embodiment 3

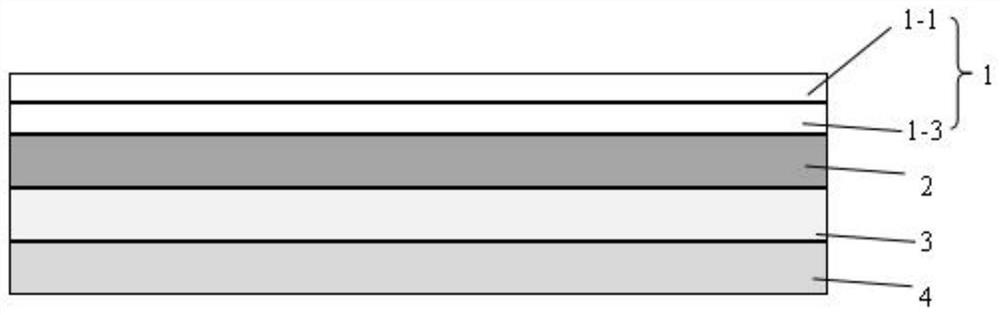

[0060] Embodiment 3 provides a power generation building material comprising a composite modified finish protective layer, such as image 3 As shown, according to the composite modified decorative finish protection layer 1 in Example 1, the power generation building material includes a composite modified decorative finish protective layer 1 , a photoelectric conversion layer 2 , an adhesive film 3 and a building material base layer 4 . There is a carrier between the composite modified finishing protective layer 1 and the photoelectric conversion layer 2, and the carrier is not marked in the figure. The power generation building material is sequentially composed of a composite modified finish protection layer 1, a photoelectric conversion layer 2, an adhesive film 3 and a building material base layer 4 from top to bottom; the composite modified finish protection layer 1 is transparent; the adhesive film 3 is used to seal the photoelectric conversion layer 2; the photoelectric c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spray thickness | aaaaa | aaaaa |

| Spray thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com