Gas oil base invert oil-emulsion drilling fluid and preparation method

A technology for emulsifying drilling fluid and oil-based oil, applied in chemical instruments and methods, drilling compositions, etc., to achieve the effect of strong anti-pollution ability, easy biodegradation and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

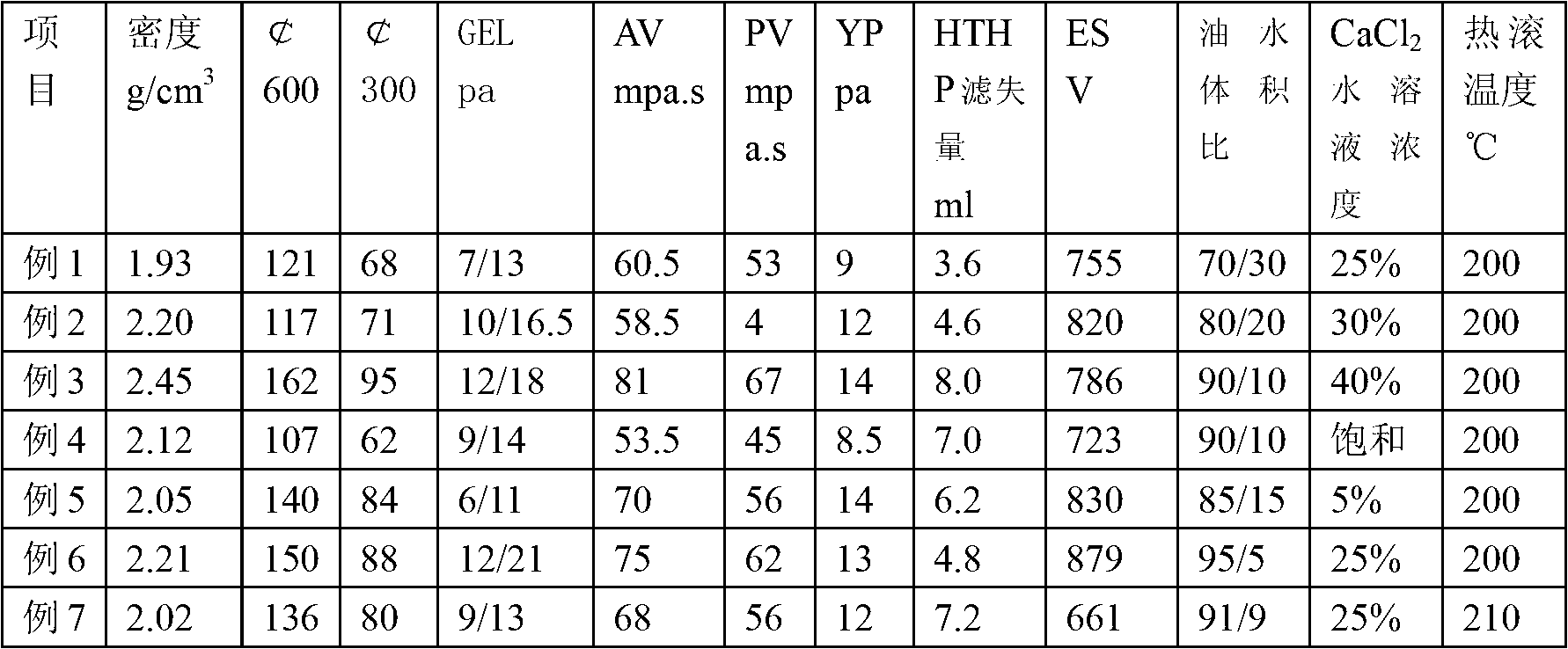

Examples

Embodiment 1

[0046] Example 1 Configured gas-to-oil-based emulsion drilling fluid with a density of 1.92 / cm3 and an oil-to-water ratio of 70 / 30

[0047] Measure 245ml of gas-based oil with a graduated cylinder and pour it into a high mixing cup. Add 3.85g of tall oil base hydrolysate after oxidation of main milk and pine pulp, and 7.0g of auxiliary milk-sodium dodecylbenzene sulfonate. Wetting agent-2.45g of the condensation reaction product of fatty acid and polyvinyl polyamine, stir it on a high-speed stirrer at 10000r / min for 5 minutes to dissolve it; add 105ml of 25% calcium chloride aqueous solution and continue stirring for 15 minutes; Then add 7g of organic soil, 10.5g of calcium oxide, 19.25g of filtrate reducer-oxidized asphalt, and continue to stir for 10 minutes; add 605g of barite and continue to stir for 20 minutes, and the required gas-to-oil-based drilling fluid is prepared.

[0048] Put the prepared oil-based drilling fluid into an aging tank, heat it at 200℃ for 16 hours, take ...

Embodiment 2

[0049] The configuration density of Example 2 is 2.12g / cm 3 , A gas-to-oil based emulsion drilling fluid with an oil-water ratio of 80 / 20

[0050] Measure 240ml gas-to-oil with a graduated cylinder and pour it into a high mixing cup, and add 3.3g of tall oil base hydrolysate after oxidation of main milk and pine pulp, and 6.0g of auxiliary milk-sodium dodecylbenzene sulfonate. Wetting agent-2.45g of the condensation reaction product of fatty acid and polyvinyl polyamine, stir on a high-speed stirrer at 11000r / min for 5 minutes to dissolve; add 60ml of 30% calcium chloride aqueous solution, and continue to stir 15 Add 6g of organic soil, 9g of calcium oxide, 16.5g of filtrate reducer-oxidized asphalt, and continue to stir for 10 minutes; add 750g of barite and continue to stir for 25 minutes. The required gas-to-oil-based drilling fluid is prepared.

[0051] Put the prepared oil-based drilling fluid into an aging tank, heat it at 200°C for 16 hours, take it out to cool down, pour it...

Embodiment 3

[0052] The configuration density of Example 3 is 2.45g / cm 3 , A gas-to-oil based emulsion drilling fluid with an oil-water ratio of 90 / 10

[0053] Measure 270ml gas-based oil with a graduated cylinder and pour it into a high mixing cup, and add 2.4g of tall oil base hydrolysate after oxidation of main milk and pine pulp, and 5.40g of auxiliary milk-sodium dodecylbenzene sulfonate. Wetting agent-the condensation reaction product of fatty acid and polyvinyl polyamine 3.0g, stir it on a high-speed stirrer at 12000r / min for 5 minutes to dissolve; add 30ml of 40% calcium chloride aqueous solution and continue stirring for 15 minutes Add 6g of organic soil, 9g of calcium oxide, 16.5g of filtrate reducer-oxidized asphalt, and continue to stir for 15 minutes; add 1160g of barite and continue to stir for 25 minutes. The preparation of the required gas-to-oil-based emulsion drilling fluid is completed.

[0054] Put the prepared oil-based drilling fluid into an aging tank, heat it at 200°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com