PVB (polyvinyl butyral) glass sandwich layer membrane sheet production line and operating method thereof

A production line and membrane technology, which is applied to other household appliances, flat products, household appliances, etc., can solve the problems of poor durability, easy aging, and loss of effectiveness, so as to improve and stabilize the molecular structure of the membrane and improve the membrane quality. Tablet performance and effect of reduction of impurity components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

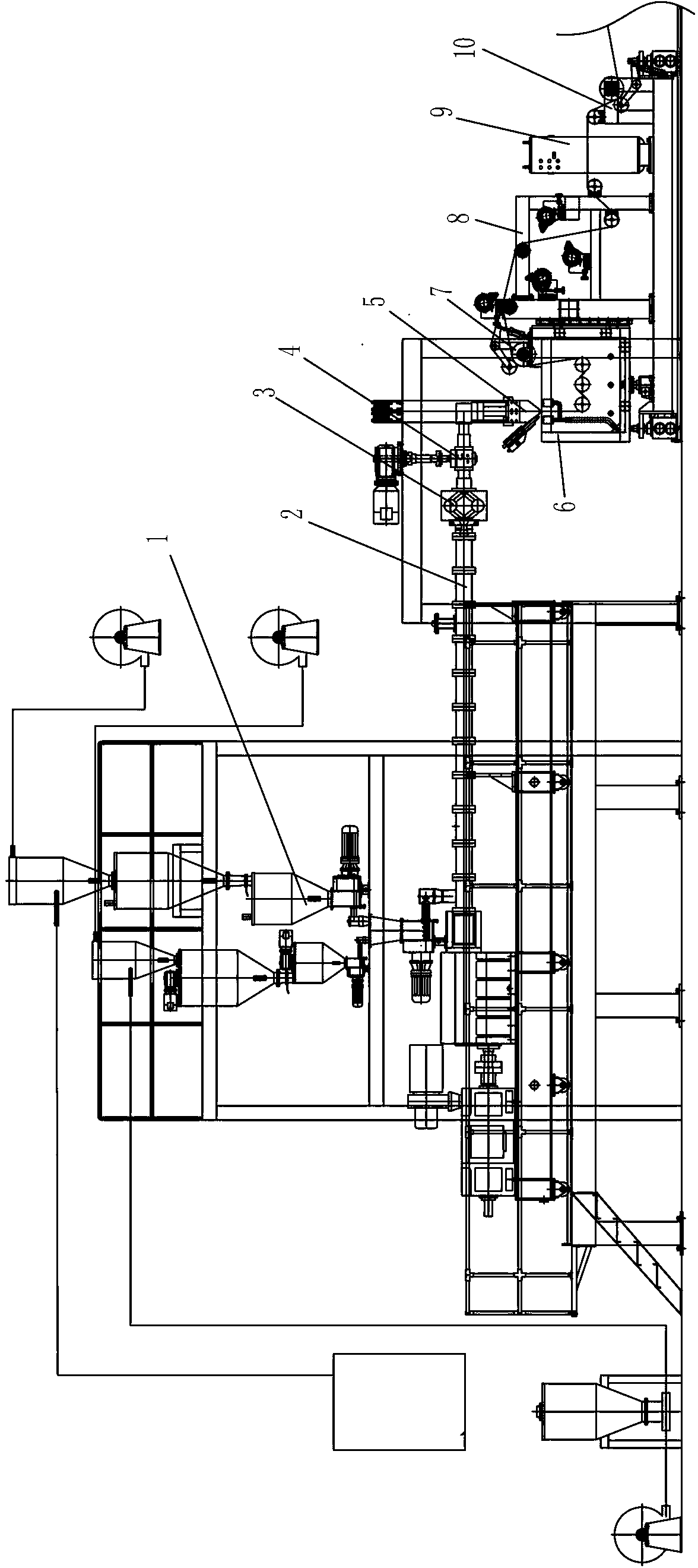

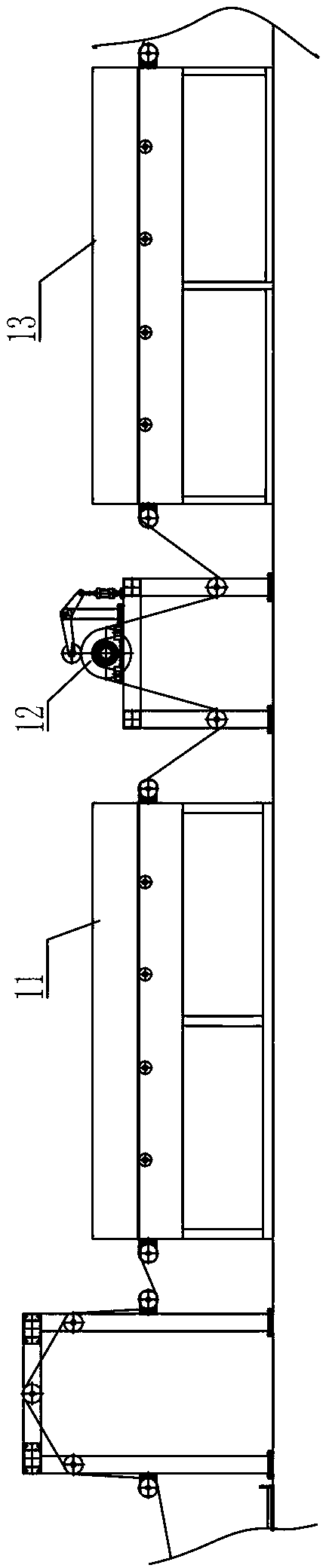

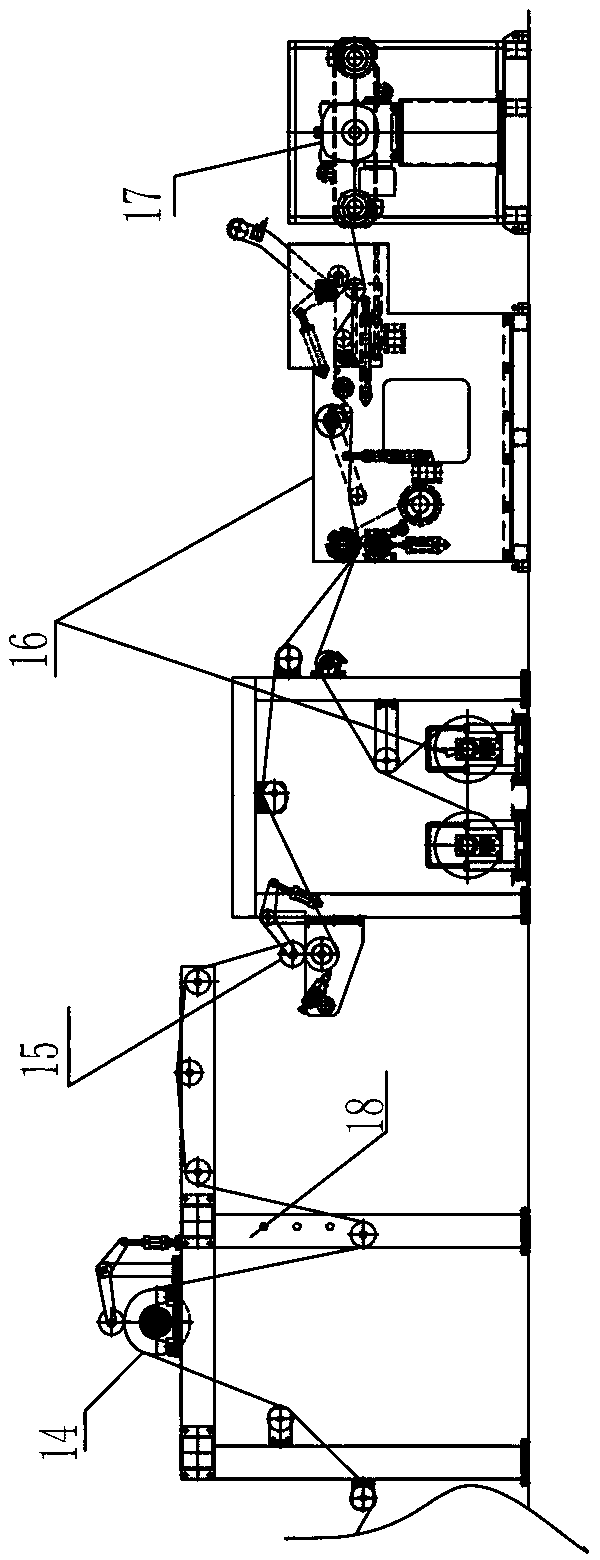

[0025] Such as Figure 1-5 , the PVB glass interlayer film production line of the present embodiment comprises: batching device 1, the extruder 2 that is used to melt the batching into a colloidal output that is connected with the output end of the batching device 1 is connected with the output end of the extruder 2 A screen changer 3 for filtering impurities, a die head 5 connected to the screen changer 3 through a metering pump 4, a feed port connected to the output end of the die head 5 for cooling the diaphragm output from the die head 5 The cooling water tank 6 of the cooling water tank 6 is connected with the discharge end of the cooling water tank 6 and is used to pull the first traction unit 7 of the diaphragm, and the dryer 8 connected with the output end of the first traction unit 7 is located at the dryer 8 The second traction unit 10 at the discharge end, the thickness gauge 9 arranged between the dryer 8 and the second traction unit 10, the devices for improving a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com